Preparation method of pre-paved waterproof membrane for concrete mortar bonded construction

A technology of concrete mortar and waterproof membrane, applied in the direction of chemical instruments and methods, lamination, layered products, etc., can solve the problems of cement-based particle isolation layer, poor water resistance, ultraviolet aging performance, increased production cost, poor aging resistance, etc. , to achieve the effect of eliminating ultraviolet aging problems, good water resistance, excellent weather resistance and water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

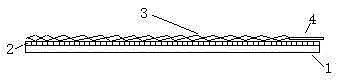

Image

Examples

Embodiment 1

[0048] 1. Preparation method of modified polyethylene plastic waterproof main layer

[0049] First, 70 parts of high-density polyethylene resin, 30 parts of linear low-density polyethylene resin, 10 parts of thermoplastic elastomer resin, 0.5 part of antioxidant 1010, 0.5 part of antioxidant 168 and 2 parts of titanium dioxide are added to the mixer, Mix and stir for 5 minutes; then add the mixture into a single-screw extruder, and extrude a modified polyethylene plastic waterproof main layer diaphragm with a thickness of 0.8mm. The operating process parameters are respectively that the temperature of the screw is 140-210°C, the temperature of the mold is 190-220°C and the temperature of the three rolls is 40-70°C.

[0050] 2. Preparation method of SIS hot-melt pressure-sensitive self-adhesive

[0051] First, add 15 parts of naphthenic white oil, 20 parts of polyisobutylene, 0.5 part of antioxidant 1010, 0.5 part of antioxidant 168 and 45 parts of petroleum resin with a softe...

Embodiment 2

[0056] 1. Preparation method of modified polyethylene plastic waterproof main layer

[0057] First, 90 parts of high-density polyethylene resin, 30 parts of linear low-density polyethylene resin, 20 parts of thermoplastic elastomer resin, 0.8 part of antioxidant 1010, 1.2 parts of antioxidant 168 and 4 parts of titanium dioxide are added to the mixer, Mix and stir for 5 minutes; then add the mixture into a single-screw extruder, and extrude a modified polyethylene plastic waterproof main layer diaphragm with a thickness of 1.0mm. The operating process parameters are respectively that the temperature of the screw is 140-210°C, the temperature of the mold is 190-220°C and the temperature of the three rolls is 40-70°C.

[0058] 2. Preparation method of SIS hot-melt pressure-sensitive self-adhesive

[0059] First, add 30 parts of naphthenic white oil, 30 parts of polyisobutylene, 0.8 parts of antioxidant 1010, 1.2 parts of antioxidant 168, and 50 parts of petroleum resin with a s...

Embodiment 3

[0066] 1. Preparation method of modified polyethylene plastic waterproof main layer

[0067] First, add 60 parts of high-density polyethylene resin, 10 parts of linear low-density polyethylene resin, 0.5 part of antioxidant 1010 and 1 part of titanium dioxide into the mixer, mix and stir for 5 minutes; then add the mixture to the single-screw extruder In the exiting machine, a modified polyethylene plastic waterproof main layer membrane with a thickness of 1.0mm is extruded. The operating process parameters are respectively that the temperature of the screw is 140-210°C, the temperature of the mold is 190-220°C and the temperature of the three rolls is 40-70°C.

[0068] 2. Preparation method of SIS hot-melt pressure-sensitive self-adhesive

[0069] First, add 10 parts of naphthenic white oil, 10 parts of polyisobutylene, 0.5 parts of antioxidant 168 and 30 parts of petroleum resin with a softening point of 110°C into a reactor with a stirring device and mix when the temperatu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com