Method for forming needed article and dot-matrix graphic by utilization of 3D printing platform

A dot-matrix graphics and 3D printing technology, applied in the field of 3D printing, can solve problems such as inability to fix micro-dots and easy peeling off of glue, and achieve the effect of increasing curing performance and avoiding falling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

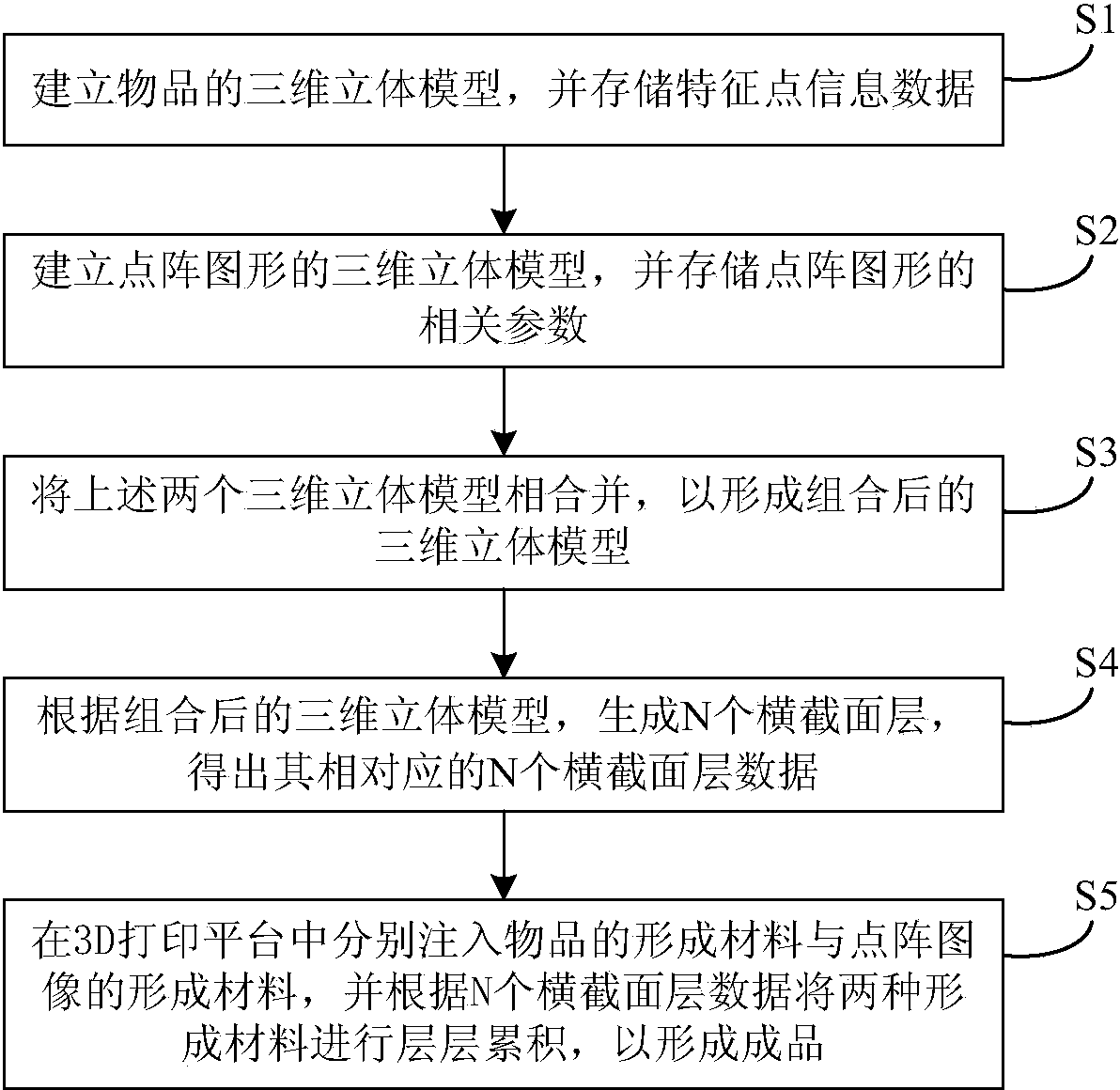

[0031] Such as figure 1 As shown, the present invention provides a method for utilizing a 3D printing platform to form required items and dot matrix graphics, comprising the following steps:

[0032] S1. Use a 3D scanner to scan the item that needs to be implanted with dot matrix graphics, and build a three-dimensional model of the item according to the feature point information data of the item, and store the feature point information data.

[0033] Wherein, the feature point information data is stored in the feature point information database.

[0034] S2. Input the relevant parameters of the dot matrix graphics, build a three-dimensional model of the dot matrix graphics, and store the relevant parameters.

[0035] In step S2, the relevant parameters of the dot matrix graphics include the area of the dot matrix graphics, the number, size, distribution, thickness, shape and color of ink dots in the dot matrix graphics, and the relevant parameters of the above dot matrix gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com