Welding device for fuel injector bases

A technology of injector seat and welding device, applied in welding equipment, resistance welding equipment, transportation and packaging, etc., can solve problems such as poor welding points, reduced product quality, inaccurate welding positioning, etc., to achieve convenient maintenance and ensure installation. Angle, the effect of improving the quality of projection welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

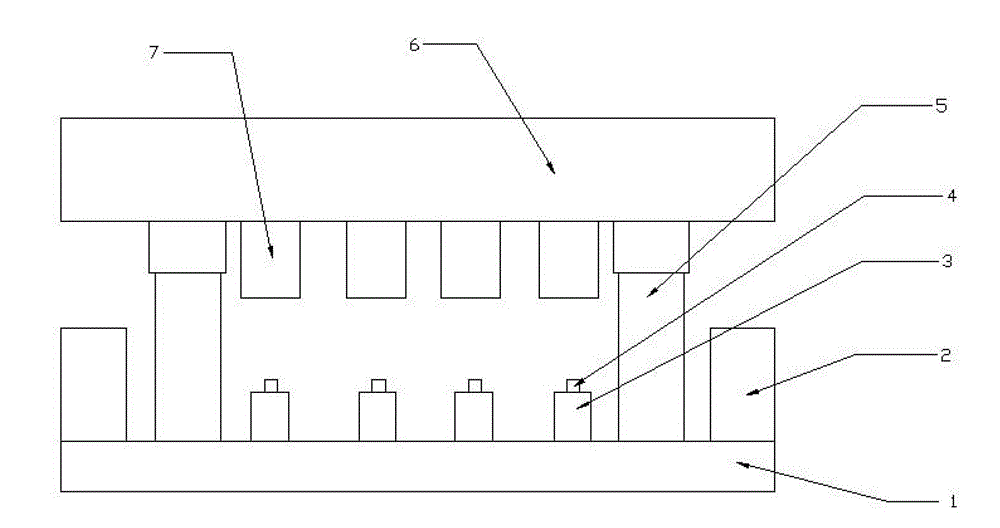

[0020] Such as figure 1 As shown, a welding device for the fuel injector seat, the welding device is used for welding the fuel injector seat and the round tube, including the bottom plate 1, the cylinder 2, the fixing pin 3, the mandrel 4, the guide rail 5, the top plate 6 and Conductive block 7, described cylinder 2, fixing pin 3 are all installed on the base plate 1, described conductive block 7 is installed on the top plate 6, and described top plate 6 is connected with base plate 1 by guide rail;

[0021] First install the fuel injector seat to be welded in the fixed pin 3, and then position and connect the round tube with the fuel injector seat through the mandrel 4, and press the conductive block 7 to press the round tube for electric welding. After welding, Cylinder 2 pushes top plate 6 out.

[0022] There are four fixed pins 3, core rods 4 and conductive blocks 7. Described fixed pin 3 is bakelite pin.

[0023] The bottom plate 1 and the top plate 6 of the present i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com