Processing method of long and thin workpiece thread and chuck fixture assembly

A technology for slender workpieces and processing methods, applied in metal processing machinery parts, manufacturing tools, metal processing equipment, etc., can solve the problems of inability to complete processing, low processing efficiency, and high labor intensity, and achieve simple and convenient use and reduced labor intensity. , the effect of expanding the length range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] like figure 1 , figure 2 As shown, when processing threads of slender parts with a length of more than 300 mm, the standard Morse quick release taper sleeve 1 is welded on the semi-finished flange 3, and then the end of the Morse taper sleeve 1 away from the flange is inserted into the taper hole of the lathe spindle and Fastening; Turning steps and end faces on the semi-finished flange 3 (the steps and end faces should match the end faces of the selected chuck fixtures to facilitate tight connection), used to connect the end of the chuck fixture 4 away from the jaws. There are at least two connecting bolts 2 (preferably 3) evenly distributed on the flange 3, which are used to connect and fasten the chuck fixture 4, and are easy to replace when different chuck fixtures need to be replaced according to the size of the slender piece. According to the size of the small square hole on the chuck fixture 4, it is necessary to make a matching chuck fixture key 6 and a booste...

Embodiment 2

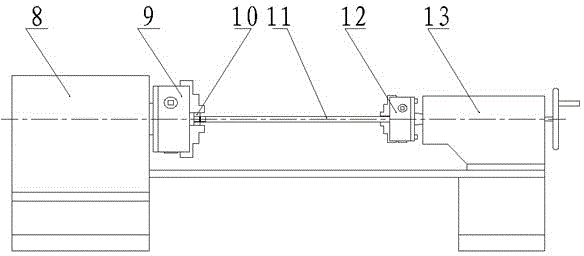

[0042] When the thread length of the processed slender parts is less than 300 mm, and the parts that do not need to be processed are longer, the workpiece 11 can be clamped on the lathe chuck 9, and the die 10 can be clamped on the chuck clamp assembly 12. The manufacturing method of the chuck fixture assembly 12 is the same as that described in the first embodiment. This facilitates the loading and unloading of the workpiece 11, and the length range of the threads of the elongated parts is wider.

[0043]Specifically, select the die 10 that is matched with the thread of the workpiece 11 to be processed, put it into the chuck clamp assembly 12 to correct and clamp firmly, and the workpiece 11 to be processed is clamped in the lathe chuck 9, and the jaws of the lathe chuck 9 and A certain clearance is maintained in the outer diameter direction of the workpiece 11 to be processed, so that the workpiece 11 to be processed can freely move axially in the chuck 9 of the lathe. Hold...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com