Conveyor system, adjustable rail assembly for the system, and method of adjusting the assembly

A transfer device, adjustable technology, applied in the direction of conveyors, transportation and packaging, rotary conveyors, etc., can solve time-consuming and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

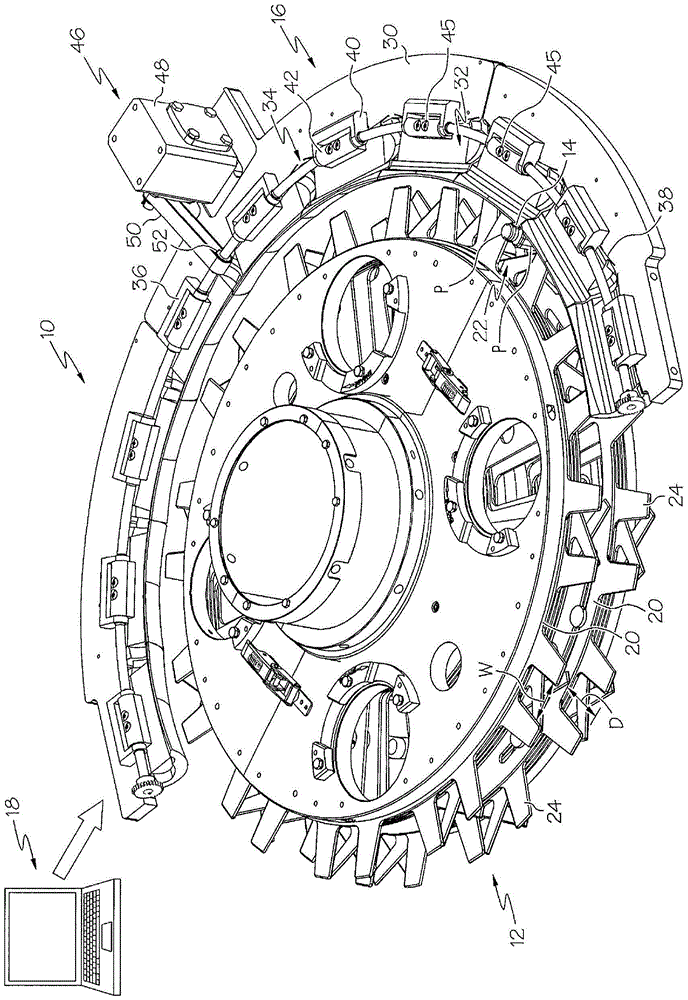

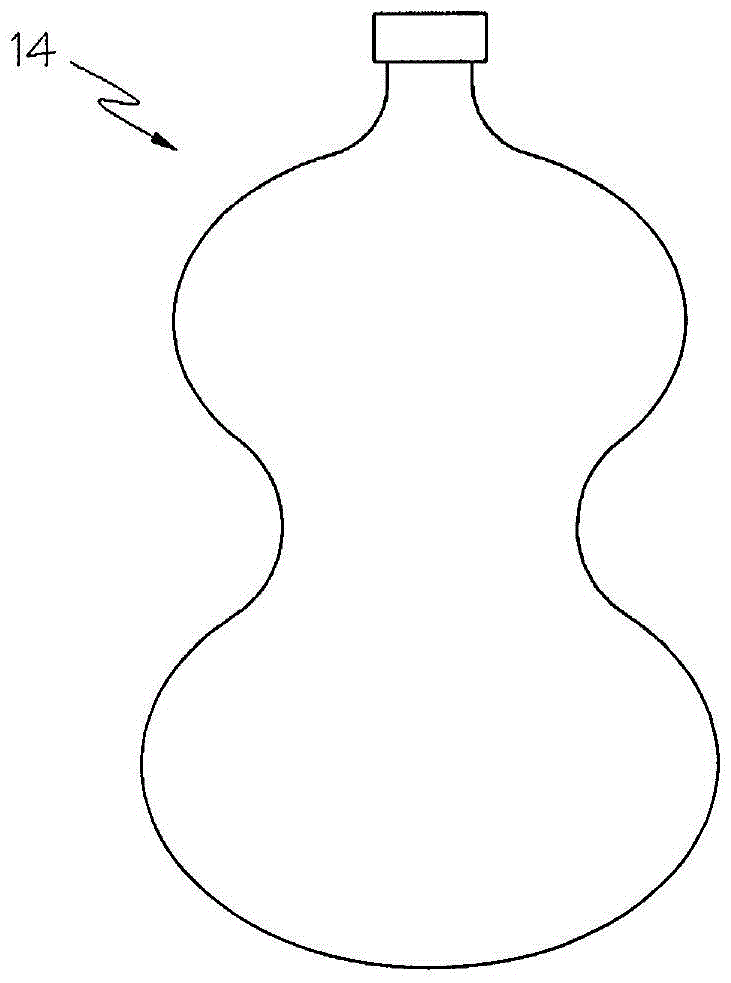

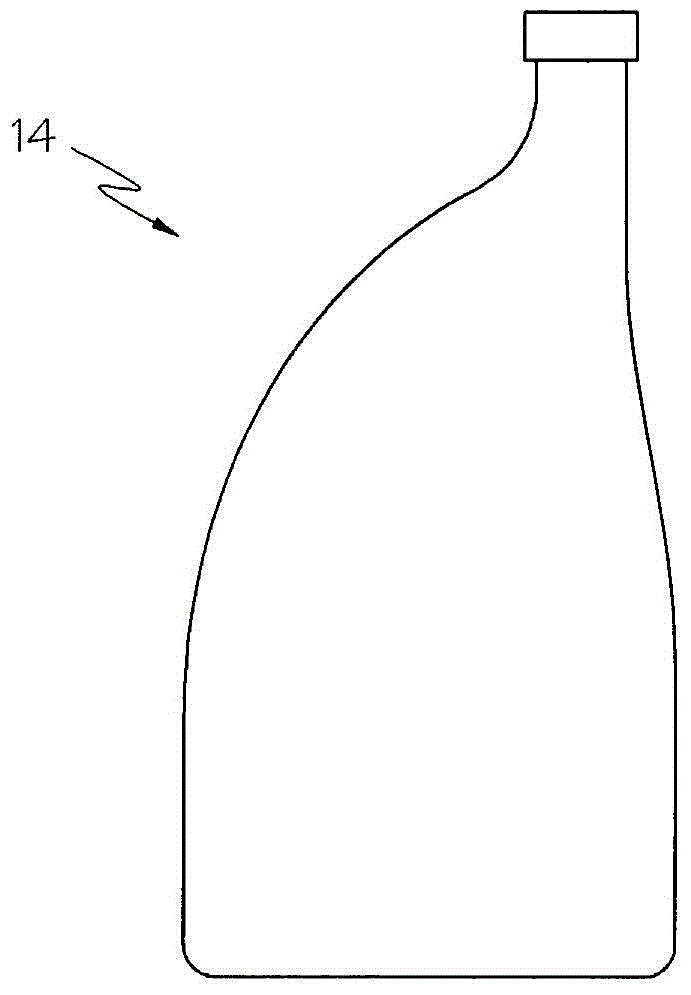

[0022] Embodiments described herein generally relate to adjustable (or reconfigurable) track assemblies. The adjustable guide rail assembly includes a plurality of individual adjustable guide members that together define an arcuate or curved guide path for a three-dimensional article (eg, container). Arc or curved guide paths may have constant or varying radii. For example, an arcuate guide path may surround a star wheel conveyor. The adjustable guide member has a profile that changes the radius of curvature of the arcuate guide path as the adjustable guide member rotates. Such a guide member configuration can accommodate three-dimensional articles of different sizes guided along an arcuate guide path.

[0023] figure 1 One non-limiting embodiment of a conveyor system 10 is shown that includes an adjustable star wheel assembly 12 for conveying three-dimensional articles about an arcuate guide path. exist figure 1 In the illustrated embodiment, the conveyor system 10 inclu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com