Method for determining content of water in sample in process of preparing composite solid propellant

A solid propellant and preparation process technology, applied in the field of physical and chemical analysis, can solve the problems of difficulty in sample introduction, easy adhesion to the test electrode, inability to uniformly disperse the test medium, etc., to achieve good dispersion, good effect, and conducive to sample injection. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

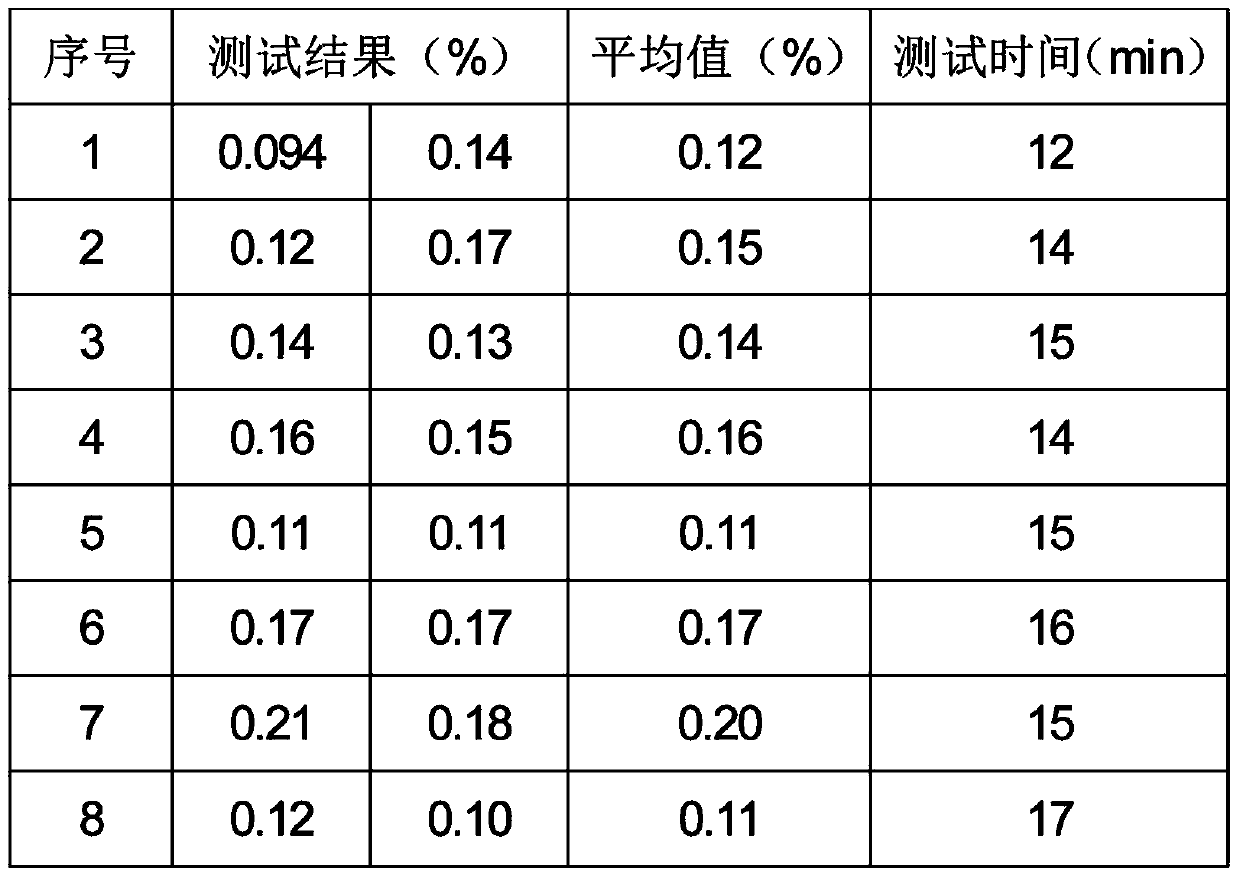

[0024] A method for assaying the moisture content of a sample during the preparation of a composite solid propellant, mainly comprising the following steps,

[0025] 1) Turn on the Karl Fischer moisture meter, titrate and remove the moisture in the methanol, then add chloroform reagent to the methanol, and titrate the chloroform moisture content, which is 0.0070%;

[0026] 2) Mix methanol and chloroform in a weight ratio of 1:1 to 1.5 as a titration solvent, add it to a titration cup, automatically add Karl Fischer solution through a Karl Fischer moisture meter, titrate to the end point, and remove the moisture in the titration solvent;

[0027] 3) Weigh the sample to be tested, take a clean 5mL syringe, weigh 0.1000g±0.0100g of the slurry sample, and place it in the syringe, accurate to 0.0001g, which are 0.1175g and 0.1135g respectively;

[0028] 4) To prepare the sample solution, add 3mL of analytically pure chloroform to the syringe containing the sample slurry, and at the...

Embodiment 2

[0035] A method for assaying the moisture content of a sample during the preparation of a composite solid propellant, mainly comprising the following steps,

[0036] 1) Turn on the Karl Fischer moisture meter, remove the moisture in the methanol by titration, then add chloroform reagent to the methanol, and titrate the chloroform moisture content, which is calculated as 0.0044%;

[0037] 2) Mix methanol and chloroform in a weight ratio of 1:1.2 as a titration solvent, add it to a titration cup, automatically add Karl Fischer solution through a Karl Fischer moisture meter, titrate to the end point, and remove the moisture in the titration solvent;

[0038] 3) Weigh M1g of the sample to be tested, accurate to 0.0001g, put it in the syringe for later use, weigh two samples, and M1 is calculated as 0.1061g and 0.1036g respectively;

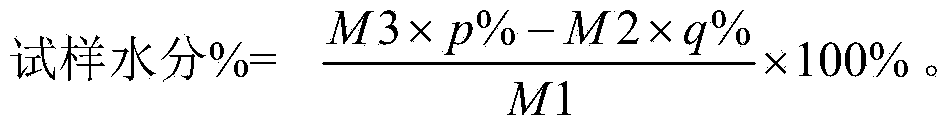

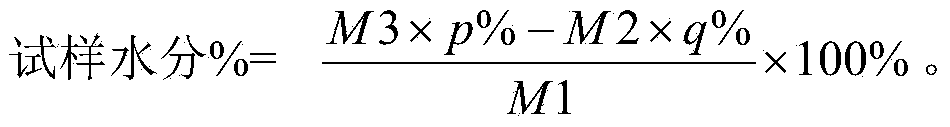

[0039] 4) Add accurately weighed M2g chloroform to the syringe of step 3), accurate to 0.0001g, then seal the needle of the syringe, put the syringe ...

Embodiment 3

[0045] A method for assaying the moisture content of a sample during the preparation of a composite solid propellant, mainly comprising the following steps,

[0046] 1) Turn on the Karl Fischer moisture meter, titrate and remove the moisture in the methanol, then add chloroform reagent to the methanol, and titrate the chloroform moisture content, which is 0.0070%;

[0047] 2) Mix methanol and chloroform in a weight ratio of 1:1.5 as a titration solvent, add it to a titration cup, automatically add Karl Fischer solution through a Karl Fischer moisture meter, titrate to the end point, and remove the moisture in the titration solvent;

[0048] 3) Weigh M1g of the sample to be tested, accurate to 0.0001g, put it in the syringe for later use, weigh two samples, and M1 is calculated as 0.1020g and 0.1311g respectively;

[0049] 4) Add accurately weighed M2g chloroform to the syringe of step 3), accurate to 0.0001g, then seal the needle of the syringe, place the syringe in a containe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com