Double-telescoping stand column of hydraulic support

A hydraulic support, double-telescopic technology, applied in pillars/supports, mining equipment, earthwork drilling and mining, etc., to achieve energy saving, energy saving and emission reduction economic benefits, and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

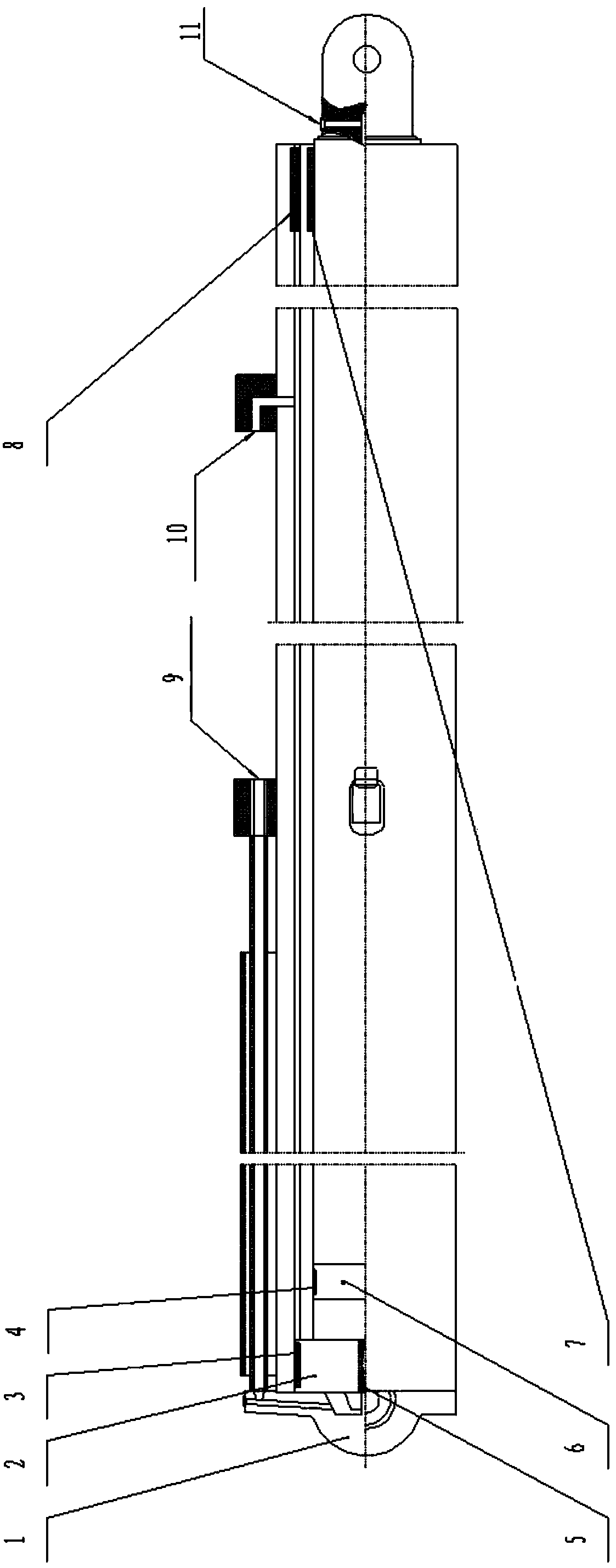

[0010] The present invention is described further in conjunction with accompanying drawing. The double telescopic column of the hydraulic support is composed of a primary telescopic column and a secondary telescopic column. The primary telescopic column includes the first cylinder body 1, the second cylinder body 2, the built-in bottom valve 5, the guide ring 3, the precision seal 8, the oil Port a9, oil port b10, the built-in bottom valve 5 is installed on one side of the inner wall of the bottom end of the first cylinder body 1 and the outer wall of the bottom end of the second cylinder body 2, and the other side is equipped with a guide ring 3, and the static seal 8 is installed in the first cylinder body Between the inner wall of the front end of the body 1 and the outer wall of the front end of the second cylinder body 2, an oil port a9 is provided in the middle of the outer wall of the first cylinder body 1, and an oil port b10 is located at the front end of the outer wal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com