Underground tunnel large dynamic water plugging method

An underground roadway and water plugging technology, applied in tunnels, shaft linings, tunnel linings, etc., can solve the problems of difficult dredging work, poor plugging effect, waste of aggregate and time, etc. The effect of small hydraulic power and large specific gravity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

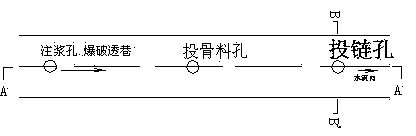

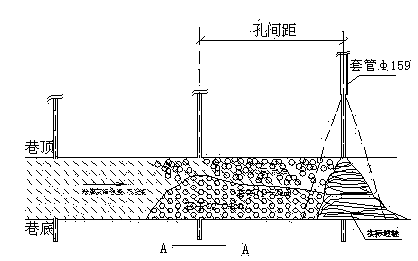

[0023] As shown in the figure, the water plugging method of large dynamic water in the underground roadway is characterized in that the process steps are:

[0024] (1) First determine the position, direction and specification shape of the roadway according to the roadway design drawing;

[0025] On the ground along the direction of the roadway, drill multiple boreholes into the permeable roadway, with a certain distance between the holes, and an orifice pipe is arranged at the upper opening of the borehole;

[0026] ⑶ Try throwing aggregates into the permeable roadway from any borehole to determine the dynamic conditions of the water inrush roadway and determine the number of iron chains to be put in;

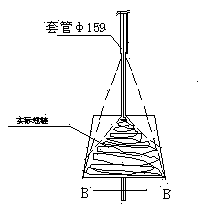

[0027] (4) Throw iron chains into the permeable roadway from the most downstream borehole, so that the iron chains are piled up into a mountain shape in the permeable roadway;

[0028] (5) Put large and small aggregates into the upstream boreholes in order from the boreholes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com