Pipe hammer system of percussion drill for rock-socketed inclined pile and impact construction method of rock-socketed inclined pile

A construction method and technology of percussion drilling, which are applied to sheet pile walls, drilling equipment, earthwork drilling, etc., can solve the problems of inconsistency between percussion drilling and sleeve axes, and the inability of percussion drilling to meet rock-socketed impact construction, etc. Shorten time, improve hole quality, and reduce the effect of sticking hammer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

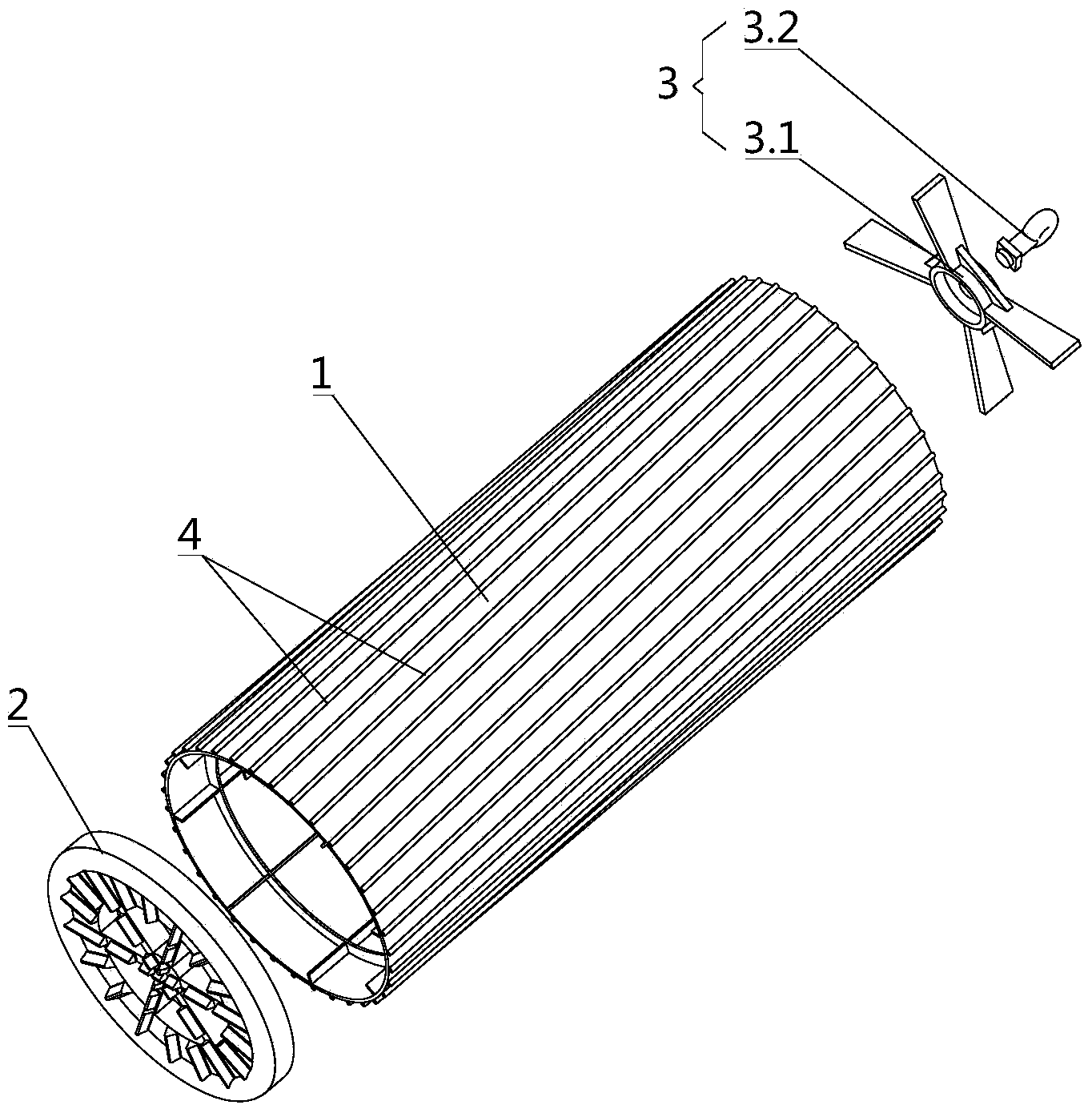

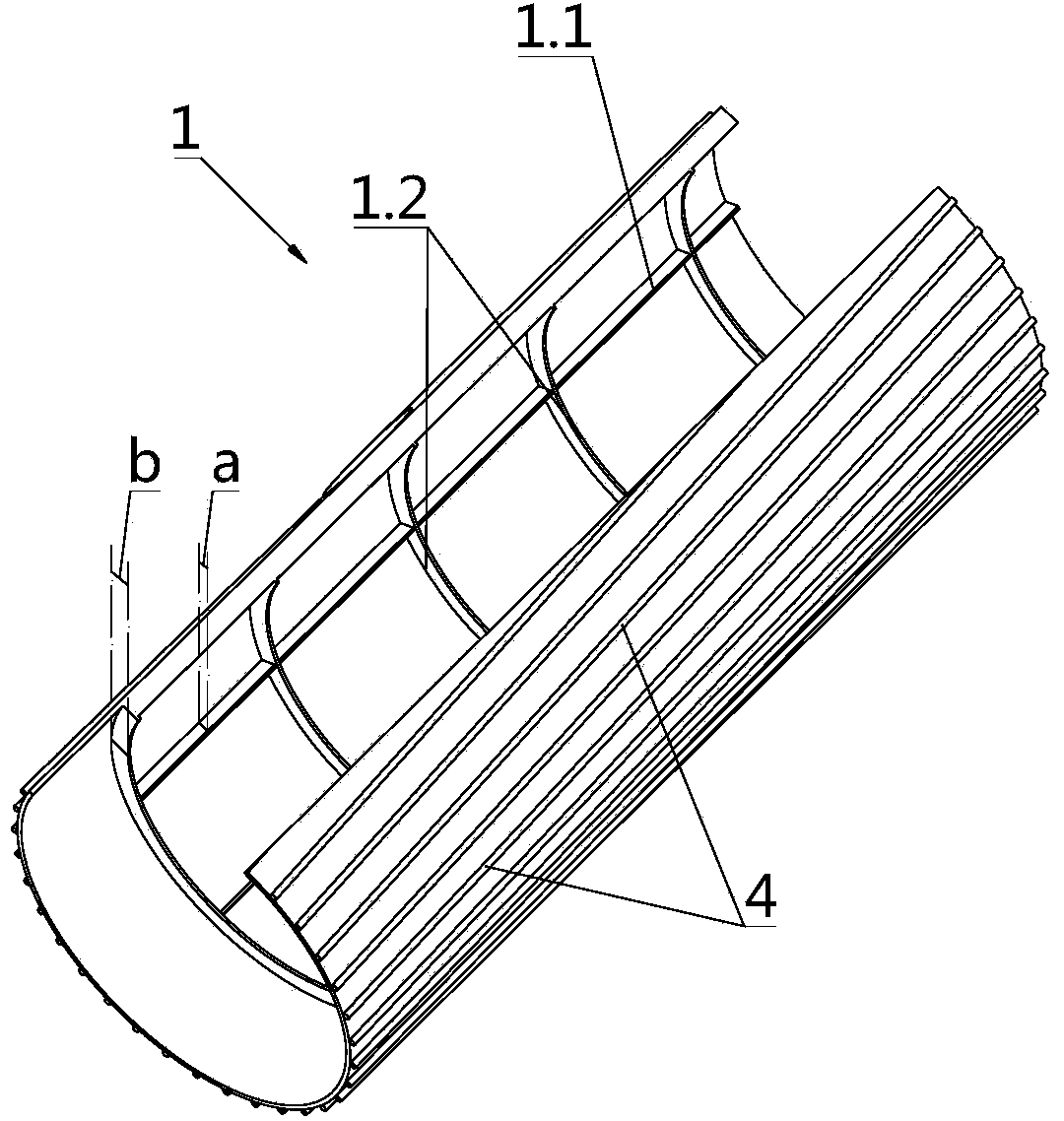

[0045] Such as figure 1 As shown, a rock-socketed inclined pile impact drill pipe hammer system designed by the present invention includes a tubular hammer body 1, a hammer head 2 is provided at one end of the tubular hammer body 1, and a hammer crane 3 is provided at the other end; the hammer head 2 includes a ring-shaped hammer head seat 2.1, and a plurality of connecting beams 2.2 are arranged inside the ring-shaped hammer head seat 2.1, and a plurality of connecting beams 2.2 are interlaced connected on the inner wall of the ring-shaped hammer head seat 2.1; A plurality of hammer teeth 2.3 are evenly distributed on the surface of the plurality of connecting beams 2.2; the hammer hanger 3 includes a hammer hanger 3.1 connected to the inner wall of the tubular hammer body 1, and the hammer hanger 3.1 is provided with a suspension ring 3.2; The outer wall of the tubular hammer body 1 is provided with a plurality of guide rods 4 at intervals; An acute angle is formed between ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com