Preparation method of 2-methyl-3-butyne-2-ol

A technology of butyne and methyl, applied in the field of preparation of 2-methyl-3-butyne-2-ol, can solve the problems of difficulty in automation, complicated production procedures, large temperature difference and concentration difference, etc. The effect of less quantity, simple process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

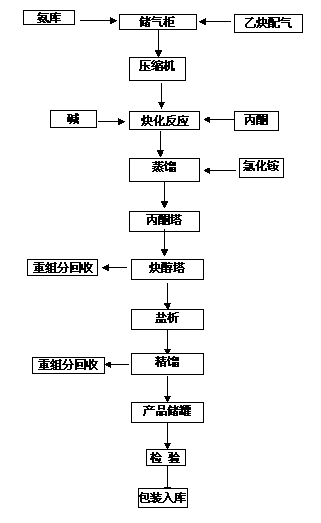

Image

Examples

Embodiment 1

[0025] In the present embodiment, its reaction steps are:

[0026] a. Turn on the liquid ammonia switch, and the ammonia in the liquid ammonia cylinder will be throttled and charged into the 2000L gas storage tank. Turn on the acetylene switch, and the acetylene will pass into the gas storage tank after being sealed with water. Acetylene gas and ammonia are mixed in the gas storage tank to adjust the amount of acetylene and ammonia entering, 520g of acetylene and 780g of liquid ammonia (the ratio of acetylene to ammonia: 1:1.5).

[0027] b. The acetylene-ammonia mixed gas passes through a 2.0L gas-liquid separator to separate the entrained liquid, and then goes to the acetylene compressor to a pressure of 1.5Mpa.

[0028] c. The acetylene ammonia mixture gas is condensed through the condenser and cooled to 30°C. According to the amount of acetone of 234 g, that is, the ratio of acetylene: acetone = 1:0.45, the acetylene ammonia mixture gas enters the 2.5L acetylenization reac...

Embodiment 2

[0038] In the present embodiment, its reaction steps are:

[0039] a. Turn on the liquid ammonia switch, and the ammonia in the liquid ammonia cylinder will be throttled and charged into the 2000L gas storage tank. Turn on the acetylene switch, and the acetylene will pass into the gas storage tank after being sealed with water. Acetylene gas and ammonia are mixed in the gas holder to adjust the amount of acetylene and ammonia entering, 260g of acetylene and 1040g of liquid ammonia (ratio of acetylene to ammonia: 1:4.0).

[0040] b. The mixed gas of acetylene and ammonia passes through a 2.0L gas-liquid separator to separate the entrained liquid, and then goes to the acetylene compressor to a pressure of 2.1Mpa.

[0041] c. The acetylene ammonia mixture gas is condensed through the condenser, cooled to 40°C, and the amount of acetone is 286 g, that is, the ratio of acetylene: acetone = 1:1.10, the acetylene ammonia mixture gas and acetone enter the 2.5L acetylenization reactor...

Embodiment 3

[0051] In the present embodiment, its reaction steps are:

[0052] a. Turn on the liquid ammonia switch, and the ammonia in the liquid ammonia cylinder will be throttled and charged into the 2000L gas storage tank. Turn on the acetylene switch, and the acetylene will pass into the gas storage tank after being sealed with water. Acetylene gas and ammonia are mixed in the gas storage tank to adjust the amount of acetylene and ammonia entering, acetylene 390g, liquid ammonia 1170g (alkyne-ammonia ratio: 1:3.0).

[0053] b. The mixed gas of acetylene and ammonia passes through a 2.0L gas-liquid separator to separate the entrained liquid, and then goes to the acetylene compressor to a pressure of 2.7Mpa.

[0054] c. The acetylene ammonia mixture gas is condensed through the condenser and cooled to 50°C. According to the amount of acetone of 292.5 g, that is, the ratio of acetylene: acetone = 1:0.75, the acetylene ammonia mixture gas enters the 2.5L acetylenization reactor together...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com