Cement mortar and preparation method thereof

A technology of cement slurry and cement, which is applied in the field of building materials, can solve the problems of low concrete strength, and achieve the effects of strong penetration resistance and freeze-thaw resistance, low bleeding rate, and low bleeding rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

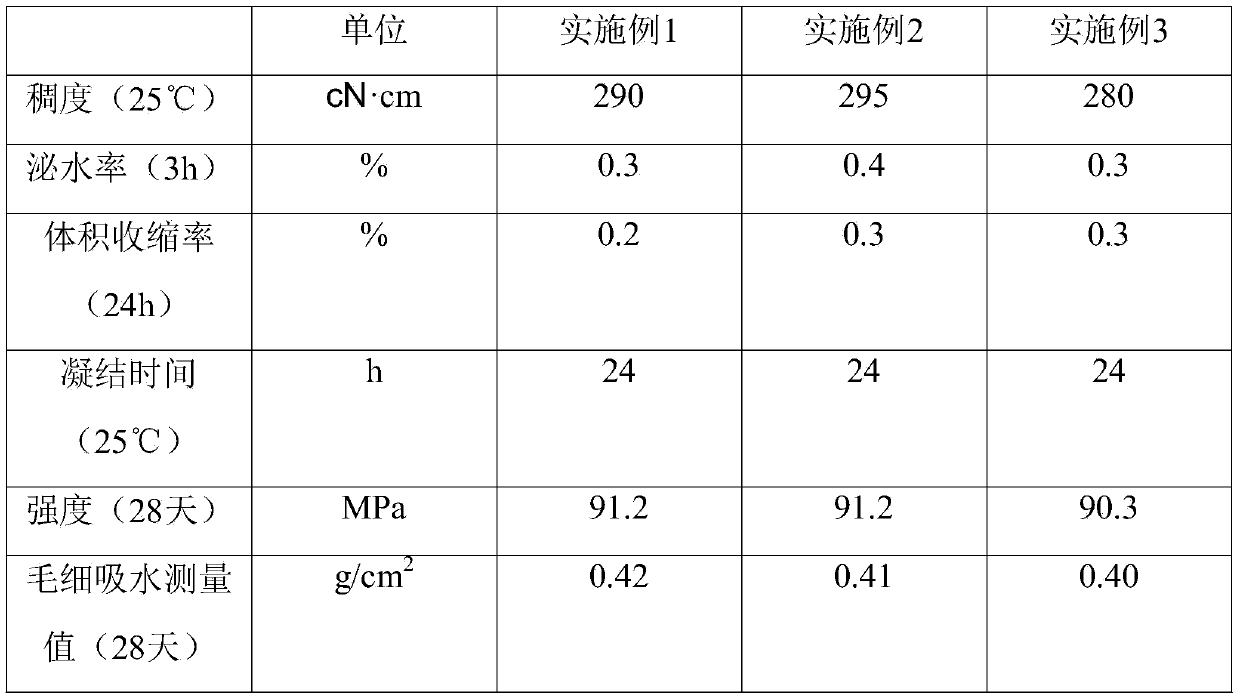

Examples

Embodiment 1

[0014] A cement slurry, comprising the following raw materials in parts by weight: 50 parts of aluminate cement and sulphoaluminate cement (weight ratio 1:1), 10 parts of zinc sulfide, 55 parts of urea-formaldehyde resin, 45 parts of sodium chloride, hydroxy 20 parts of methyl cellulose, 40 parts of diethylene glycol, 100 parts of calcium carbonate, 10 parts of antimony trioxide, 40 parts of chlorinated paraffin, 70 parts of methyl ethyl ketone, 80 parts of china clay powder (400 mesh), curing agent (weight ratio of 1:4 ammonium chloride and hexamethylenetetramine) 20 parts, water 100 parts.

[0015] The preparation method of cement slurry comprises the following steps: uniformly mixing cement, zinc sulfide, urea-formaldehyde resin, sodium chloride, hydroxymethyl cellulose, diethylene glycol, and water, heating to 200°C, stirring for 60s, adding calcium carbonate, three Antimony oxide, chlorinated paraffin, methyl ethyl ketone, china clay powder, and curing agent are mixed eve...

Embodiment 2

[0017] A cement slurry comprising the following raw materials in parts by weight: 100 parts of ferroaluminate cement, fluoroaluminate cement and phosphate cement (weight ratio 1:1:1), 50 parts of zinc sulfide, 65 parts of urea-formaldehyde resin, 55 parts of sodium chloride, 30 parts of hydroxymethyl cellulose, 80 parts of diethylene glycol, 120 parts of calcium carbonate, 50 parts of antimony trioxide, 50 parts of chlorinated paraffin, 80 parts of methyl ethyl ketone, 120 parts of china clay powder (500 mesh) 30 parts of curing agent (ammonium chloride and hexamethylenetetramine with a weight ratio of 1:5), 120 parts of water.

[0018] The preparation method of cement slurry comprises the following steps: uniformly mix cement, zinc sulfide, urea-formaldehyde resin, sodium chloride, hydroxymethyl cellulose, diethylene glycol, and water, heat to 200°C, stir for 50s, add calcium carbonate, three Antimony oxide, chlorinated paraffin, methyl ethyl ketone, china clay powder, and cu...

Embodiment 3

[0020] A cement slurry comprising the following raw materials in parts by weight: 70 parts of phosphate cement, 30 parts of zinc sulfide, 60 parts of urea-formaldehyde resin, 50 parts of sodium chloride, 25 parts of hydroxymethyl cellulose, 60 parts of diethylene glycol, carbonic acid 110 parts of calcium, 30 parts of antimony trioxide, 45 parts of chlorinated paraffin, 75 parts of methyl ethyl ketone, 90 parts of china clay powder (450 mesh), curing agent (ammonium chloride and hexamethylenetetramine with a weight ratio of 1:4.5 ) 25 parts, water 110 parts.

[0021] The preparation method of cement slurry comprises the following steps: uniformly mix cement, zinc sulfide, urea-formaldehyde resin, sodium chloride, hydroxymethyl cellulose, diethylene glycol, and water, heat to 220°C, stir for 70s, add calcium carbonate, three Antimony oxide, chlorinated paraffin, methyl ethyl ketone, china clay powder, and curing agent are mixed evenly.

PUM

| Property | Measurement | Unit |

|---|---|---|

| flow consistency | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| bleeding rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com