Modularized ship ballast water treatment system

A technology of ship ballast water and treatment system, applied in the field of modular ship ballast water treatment system, can solve the problems of unfavorable personnel use and maintenance, inconvenient installation and maintenance, unreasonable location setting, etc., to achieve convenient installation and maintenance, saving Installation time, reasonable effect of modular layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

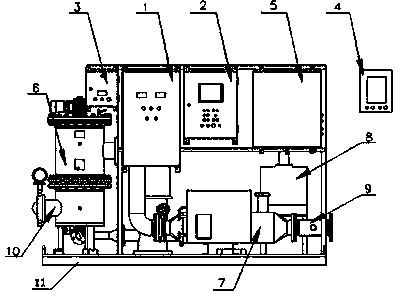

[0019] Such as figure 1 A modular ship ballast water treatment system is shown, including main cabinet 11, power distribution cabinet 1, control cabinet 2, filter control box 3, detection cabinet 5, filter 6, EUT electrocatalytic device 7, EUT power supply 8. Electromagnetic flowmeter 9, valve 10, and a remote control cabinet 4 installed in the turbine control room or cab. The control cabinet 2 is connected to the remote control unit 4 through RS485 communication cables; the main cabinet 11 is provided with vertical partitions 12, The filter control box 3, the filter 6, the valve 10 are on the side of the vertical partition 12, and are installed in the main cabinet 11 from top to bottom; the power distribution cabinet 1, the control cabinet 2, and the detection cabinet 5 are installed in the vertical partition 12 in turn On the upper part of the other side, the EUT power supply 8 is installed under the detection cabinet 5, and the EUT electrocatalytic device 7 is connected to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com