Right mounting bracket blanking and punching composite die

A technology of blanking, punching and composite molds, which is applied in the field of mechanical processing, can solve the problems of easy out-of-tolerance processing dimensions, high labor intensity, and high production costs, and achieve the effects of good dimensional consistency, low labor intensity, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

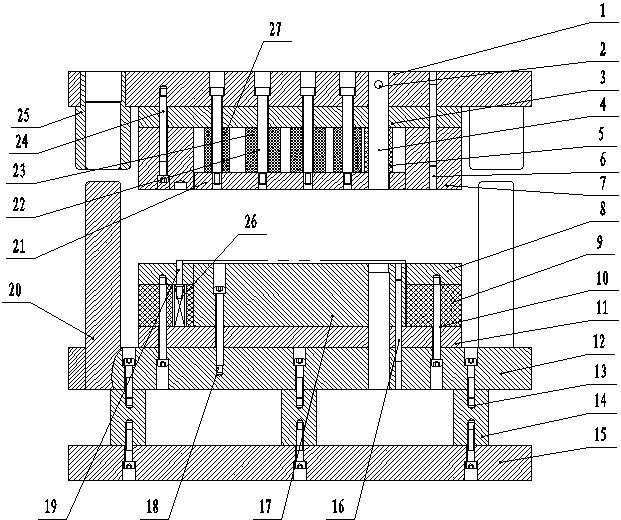

[0034] As shown in the accompanying drawings: a blanking and punching compound die for the right mounting bracket, which includes: an upper die assembly and a lower die assembly.

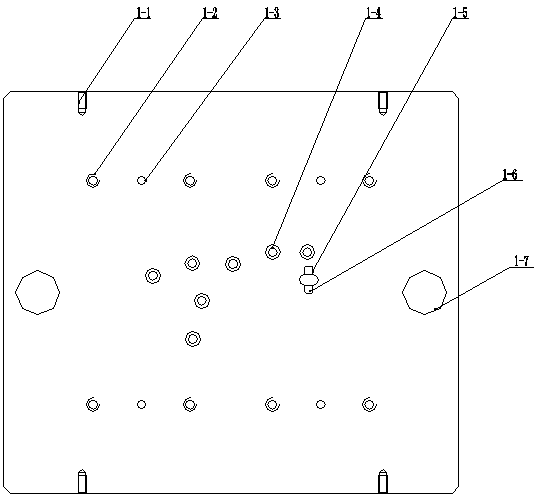

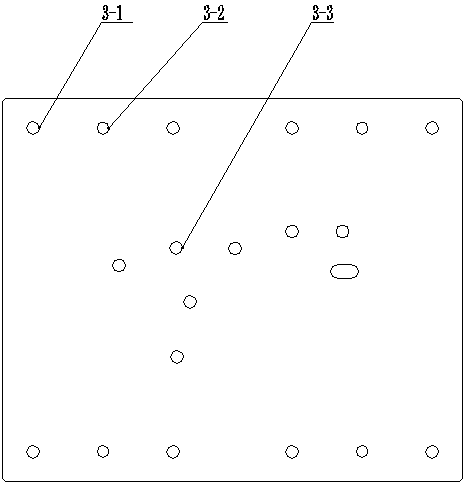

[0035] Described patrix assembly comprises patrix 1, fixed pin 2, patrix backing plate 3, square punch 4, rubber 5, the 1st cylindrical pin 6, die piece piece 7, unloading plate 21, unloading screw 22 , unloading rubber 23, hexagon socket head cap screw 24, guide sleeve 25, small round rubber 27; the upper mold base 1 is located at the top of the mold, the upper mold backing plate 3 is located under the upper mold base 1, and the die block 7 is located on the upper Below the die backing plate 3, the die block 7, the upper die backing plate 3, the upper die seat 1 are connected together by the hexagon socket head cap screw 24 and the 1st cylindrical pin 6, the discharge plate 21, the rubber 5, the discharge rubber 23. The small round rubber 27 is located in the blanking hole in the middle of the die ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com