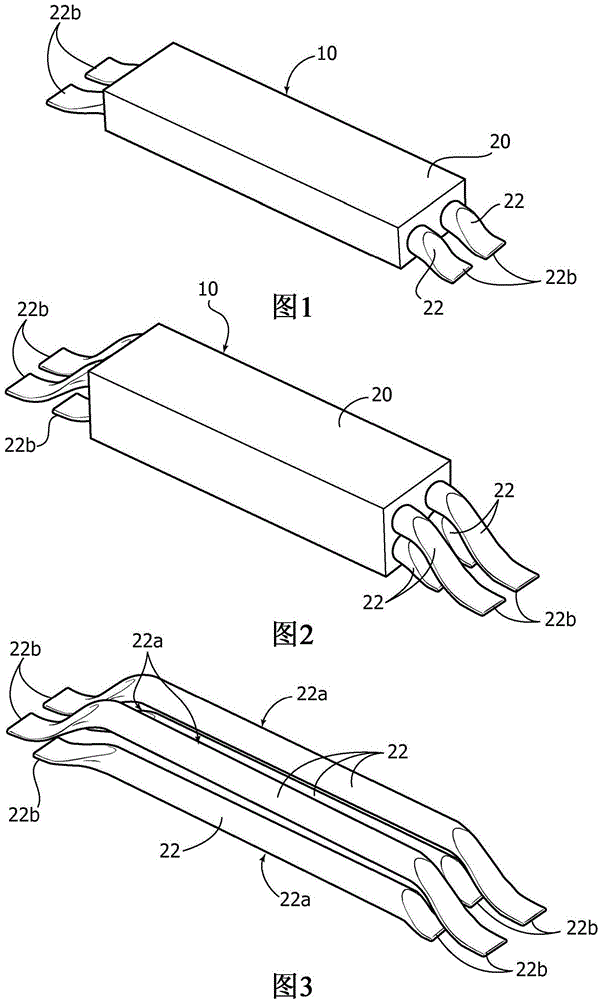

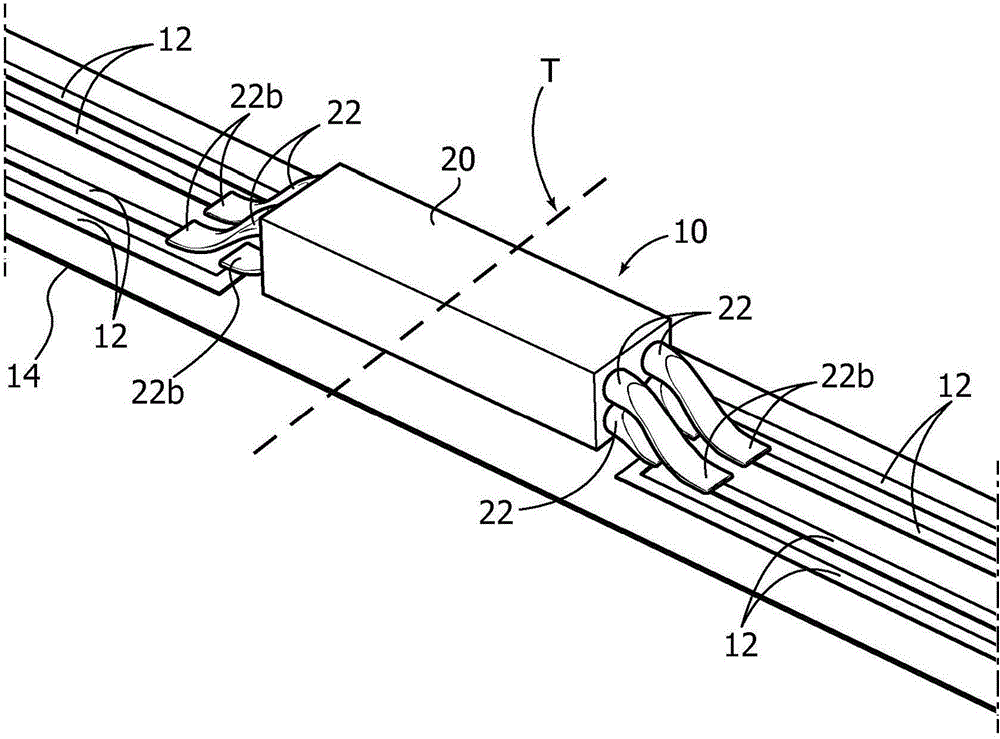

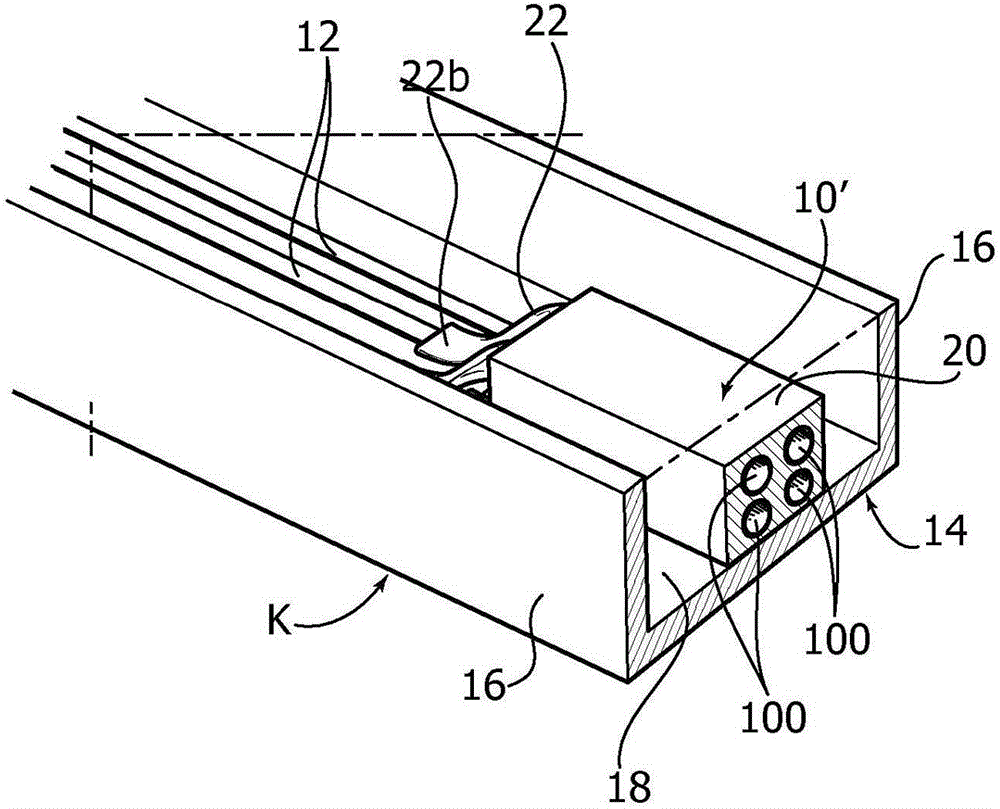

Method of producing flexible electrical cords and connector therefor

A flexible technology for electrical connectors, applied in the direction of reducing the size of conductors/cables, manufacturing contacts, manufacturing cables/conductors, etc., can solve problems such as damage to lighting modules, difficulties, inconvenient use of connectors, etc., to achieve size reduction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following description illustrates various specific details to provide a better understanding of the embodiments. One or more of the specific details may not be employed, or other methods, components, materials, etc. may be used in the manufacture of the described embodiments. In other instances, well-known structures, materials, or operations are not shown or described in detail to avoid obscuring aspects of the embodiments.

[0022] The "one embodiment" mentioned in this specification is used to indicate that the specific configuration, structure or feature of this embodiment is included in at least one embodiment. Thus, phrases such as "in one embodiment," which may appear in various parts of this specification, are not necessarily referring to the same embodiment. In addition, in one or more embodiments, certain constituents, structures or characteristics may be combined together in an appropriate manner.

[0023] References used herein are for convenience only...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com