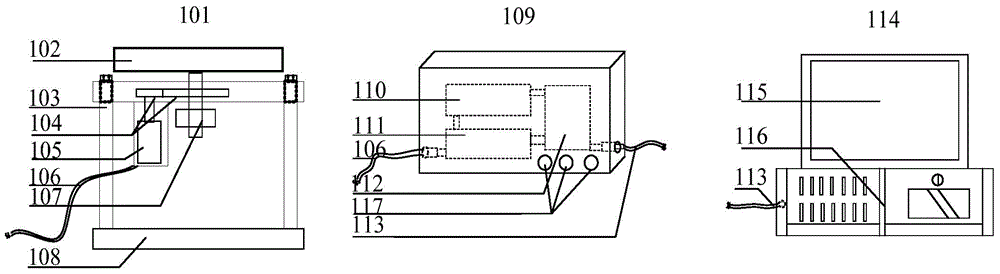

Precise servo mechanism resonance frequency testing system and testing method

A servo mechanism and resonant frequency technology, which is applied in the field of test systems for the resonance frequency of precision servo mechanisms, can solve the problems of difficult connection, difficult to control the tapping force, low repeatability, etc., so as to reduce the requirements of mechanical structure and reduce technical pressure. , operating the programmatic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

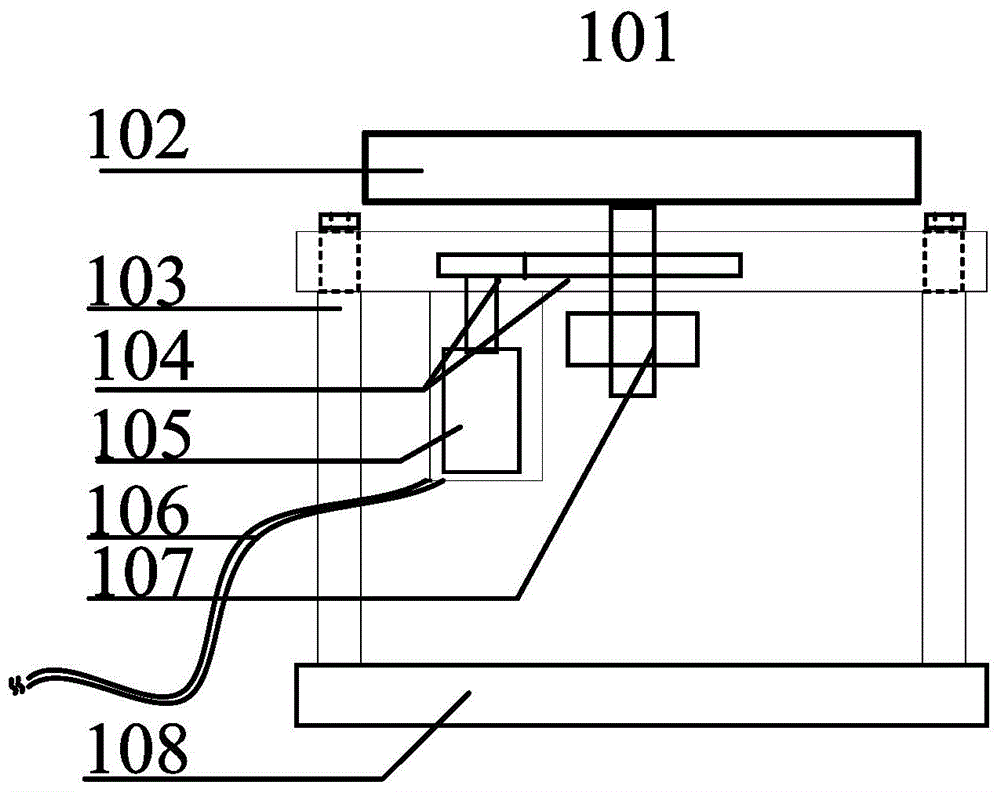

Method used

Image

Examples

Embodiment 2

[0068] The present invention also provides embodiment 2, adopts step method to test resonant frequency, comprises the following steps:

[0069]1) Initialize the system at first, set the motor driver 111 of the servo mechanism parameter tester 109 and the servo mechanism control parameter PID of the multi-axis motion control card 112 on the industrial computer 114;

[0070] 2) Then set the parameters of the excitation signal on the industrial computer, including the excitation signal S t (t) Amplitude V max , the excitation time t scan , where the excitation signal S in the step method t (t) Amplitude u rated is the rated voltage of the motor, and the excitation time is 100ms≤t scan ≤300ms;

[0071] 3) Setting keys for different position sensors on the sensor selection switch of the servo mechanism parameter tester; and selecting corresponding data transmission processing modules corresponding to different position sensors on the data conversion processing card;

[0072...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com