Rapid testing method for optical fiber gyroscope scale factor parameter

A fiber optic gyroscope and scaling factor technology, applied in the direction of measuring devices, instruments, etc., can solve the problems of easy wear, short life, long life, generally a few minutes to tens of minutes, etc., to achieve small damage, low requirements, and test time short effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the accompanying drawings.

[0038] The present invention adopts following steps:

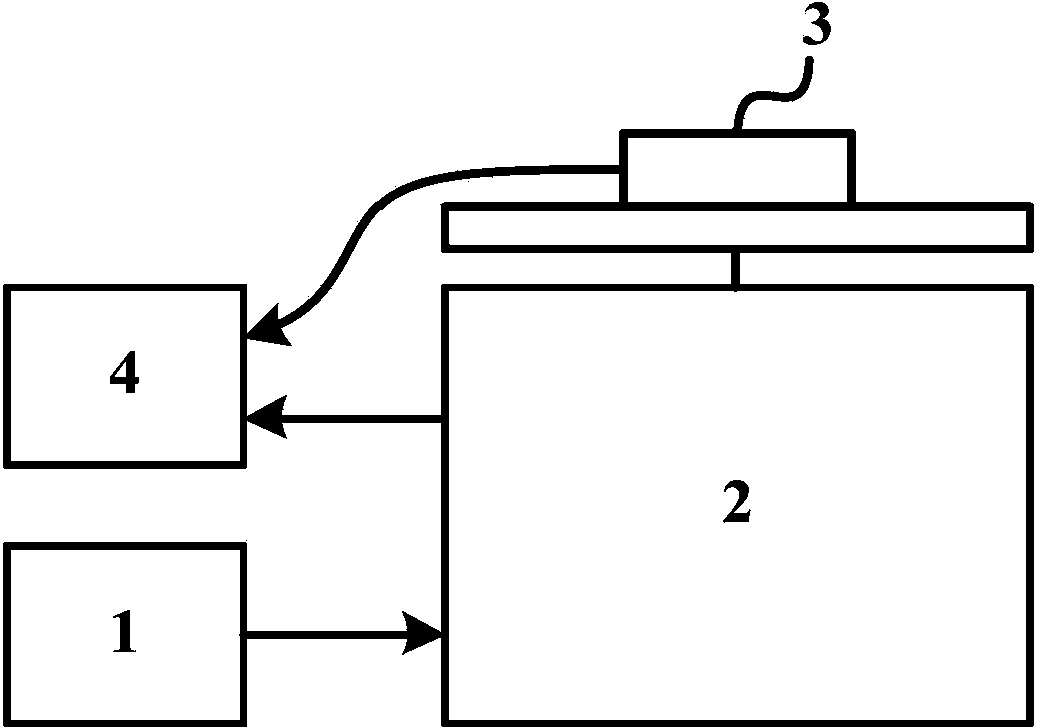

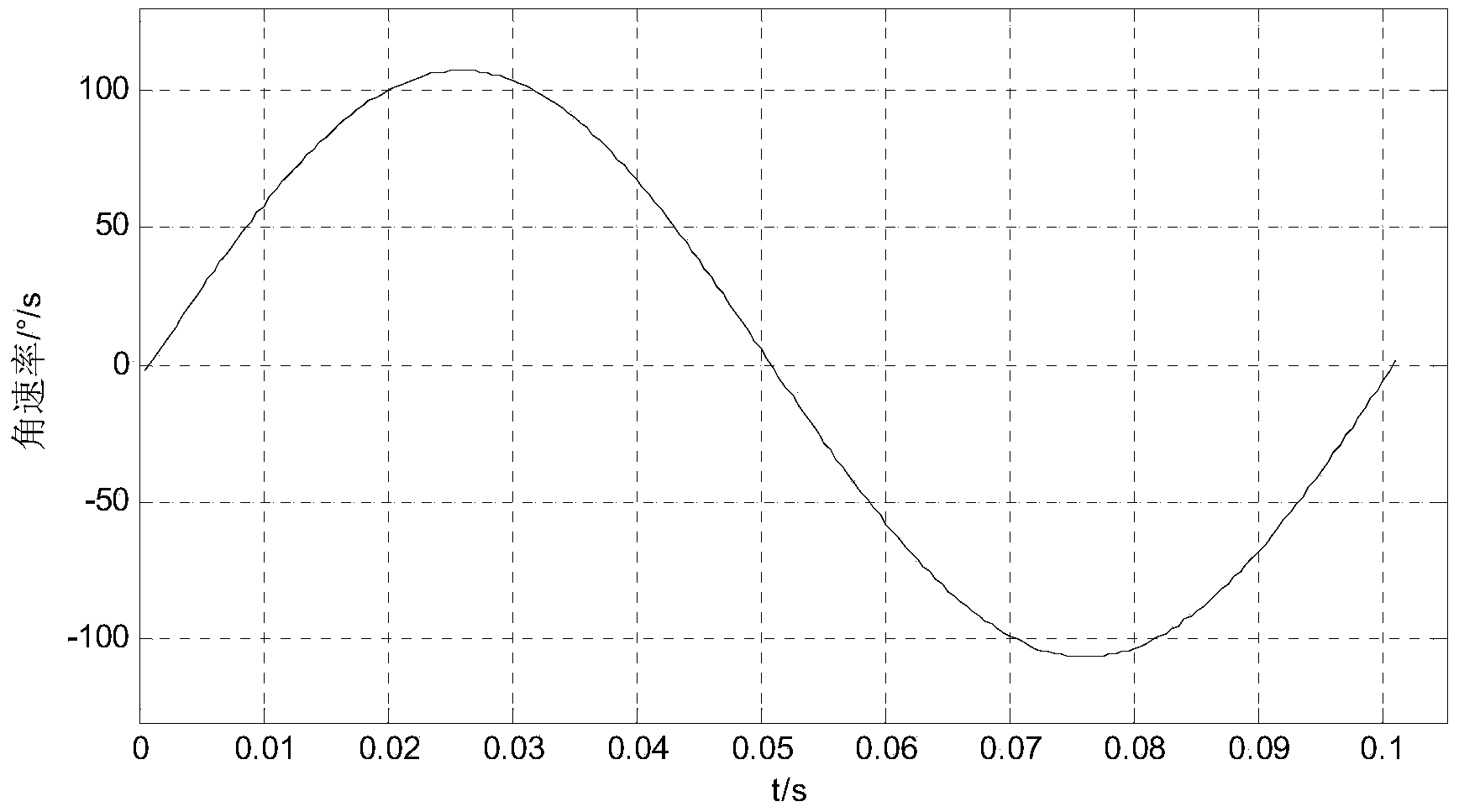

[0039] 1) if figure 1 As shown, the fiber optic gyroscope 3 is fixedly installed on the turntable 2, and the turntable 2 is controlled to rotate at a sinusoidal angular rate Ω(t)=Ωsin(2πft), and the fiber optic gyroscope 3 follows the turntable 2 to rotate at the same angular rate, where Ω is The magnitude of the sinusoidal angular rate, f is the frequency of the sinusoidal angular rate, and t is the time;

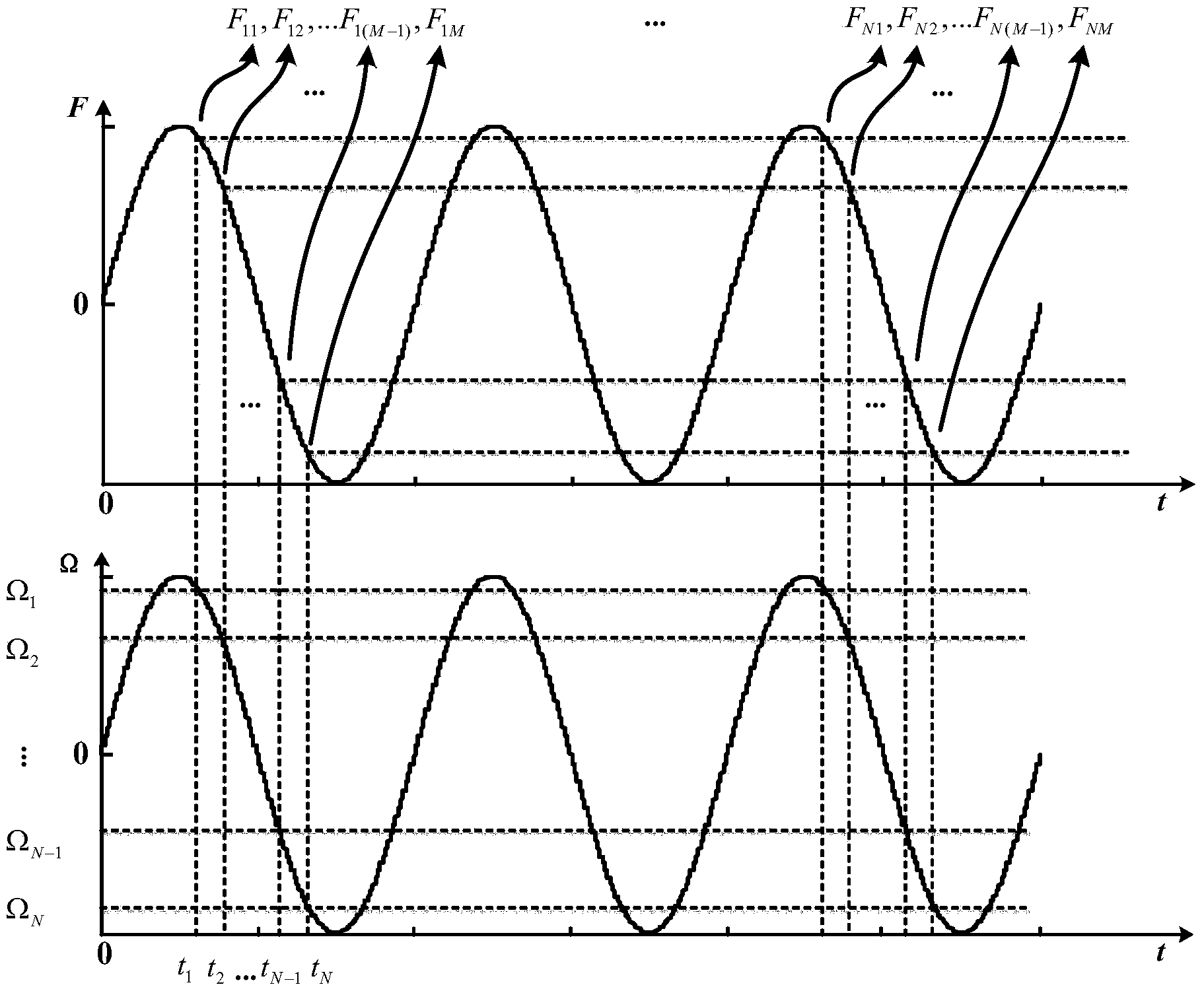

[0040] 2) Collect the output digital quantity of the fiber optic gyroscope 3 and the rotational sine angular rate of the turntable 2, and obtain the output digital quantity F(t) of the fiber optic gyroscope 3 and the rotational sine angular rate Ω(t) of the turntable 2 at different time points t ;

[0041] 3) Perform linear least squares fitting on the output digital quantity F(t) of the fiber optic gyroscope ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com