C/C composite material deposition furnace

A composite material and deposition furnace technology, applied in the field of direct heating C/C composite material preparation, can solve the problems of complex equipment, long preparation cycle, and single workpiece form, and achieve low manufacturing cost and high reliability of current conduction , good temperature uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

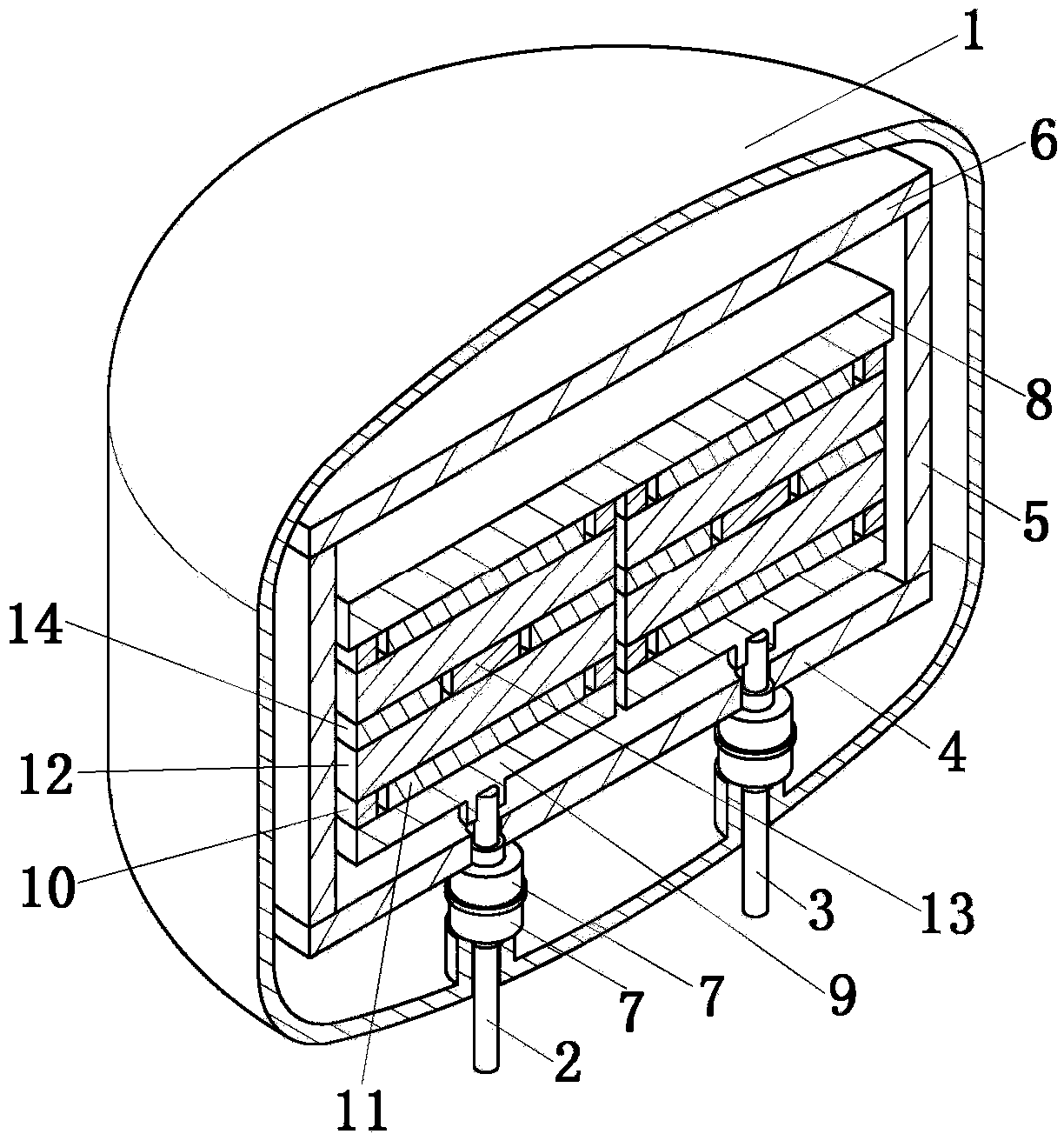

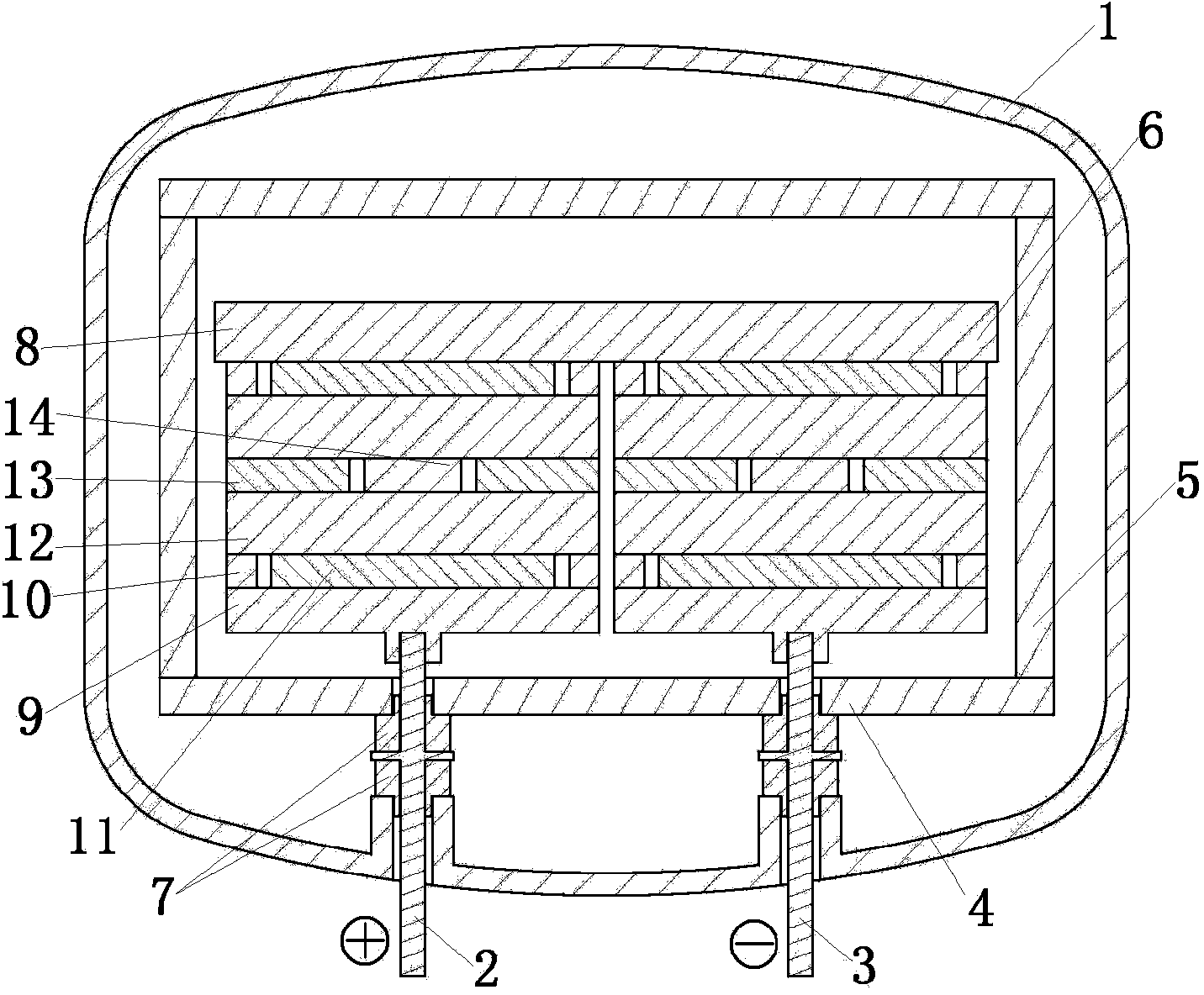

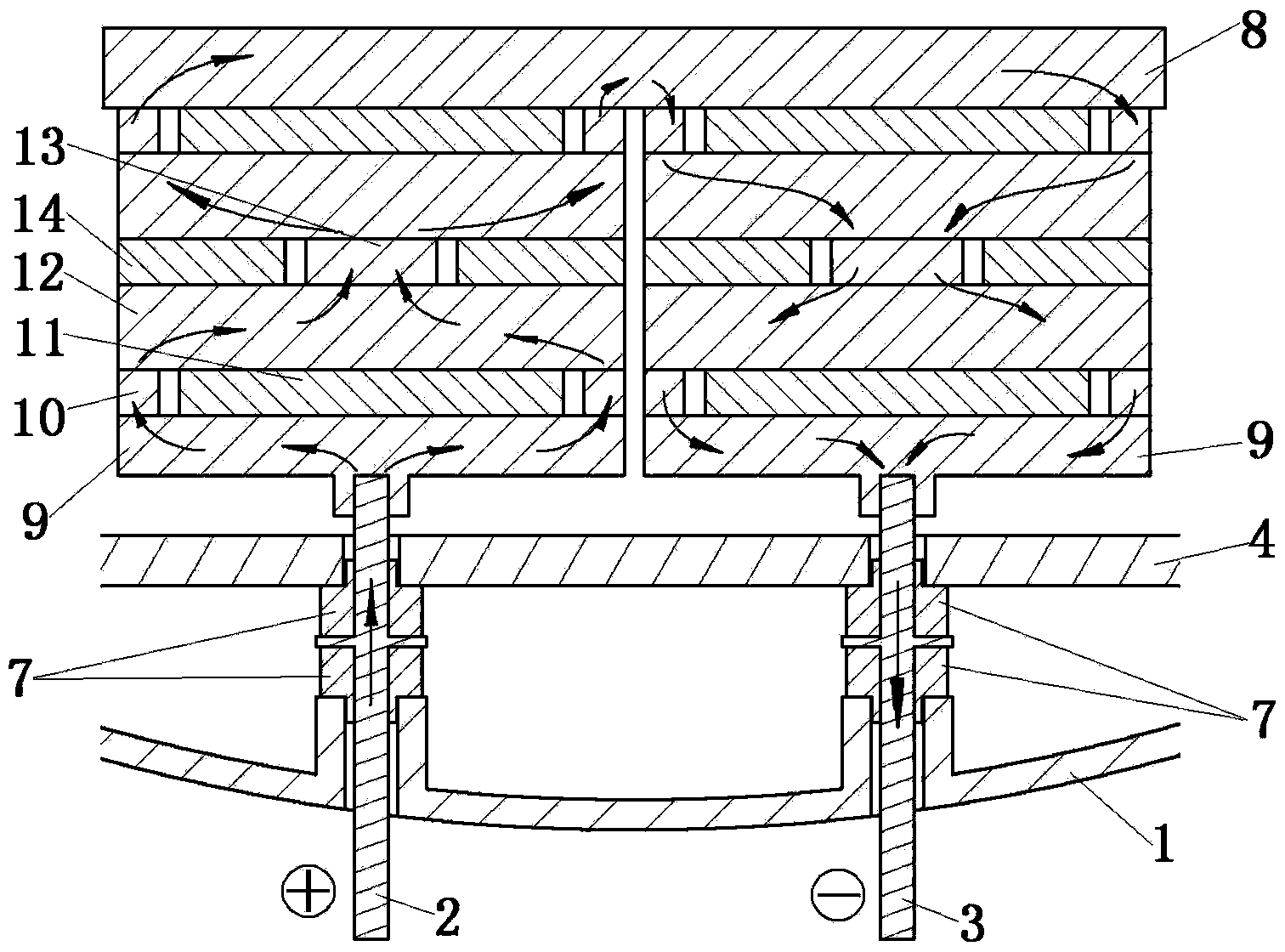

[0032] This embodiment is a C / C composite material deposition furnace with double columns.

[0033] This embodiment includes furnace shell 1, electrode rod, bottom plate 4, heat preservation barrel 5, heat preservation cover plate 6, pole plate insulation sleeve 7, conductive material tray 9, outer conductive ring 10, insulating sheet 11, workpiece 12, inner conductive sheet 13. An insulating ring 14 and a conducting plate 8 . The number of the electrode rods is the same as the number of the material columns. In this embodiment, there are two material columns, and the corresponding electrode rods are also two, which are respectively the first electrode rod 2 and the second electrode rod 3 . The number of the conductive material tray 9 and the conductive plate 8 is also the same as the number of the material column. The quantity of the outer conductive ring 10, insulating sheet 11, inner conductive sheet 13 and insulating ring 14 is determined according to the number of layer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com