Integrally prefabricated multifunctional composite external wall panel and industrial building external wall

A composite exterior wall panel and integral prefabrication technology, which is applied to buildings, building components, building structures, etc., can solve the problems of construction dust pollution, heavy weight of prefabricated panels, and increased construction costs. The effect of saving construction time and convenient hoisting and construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

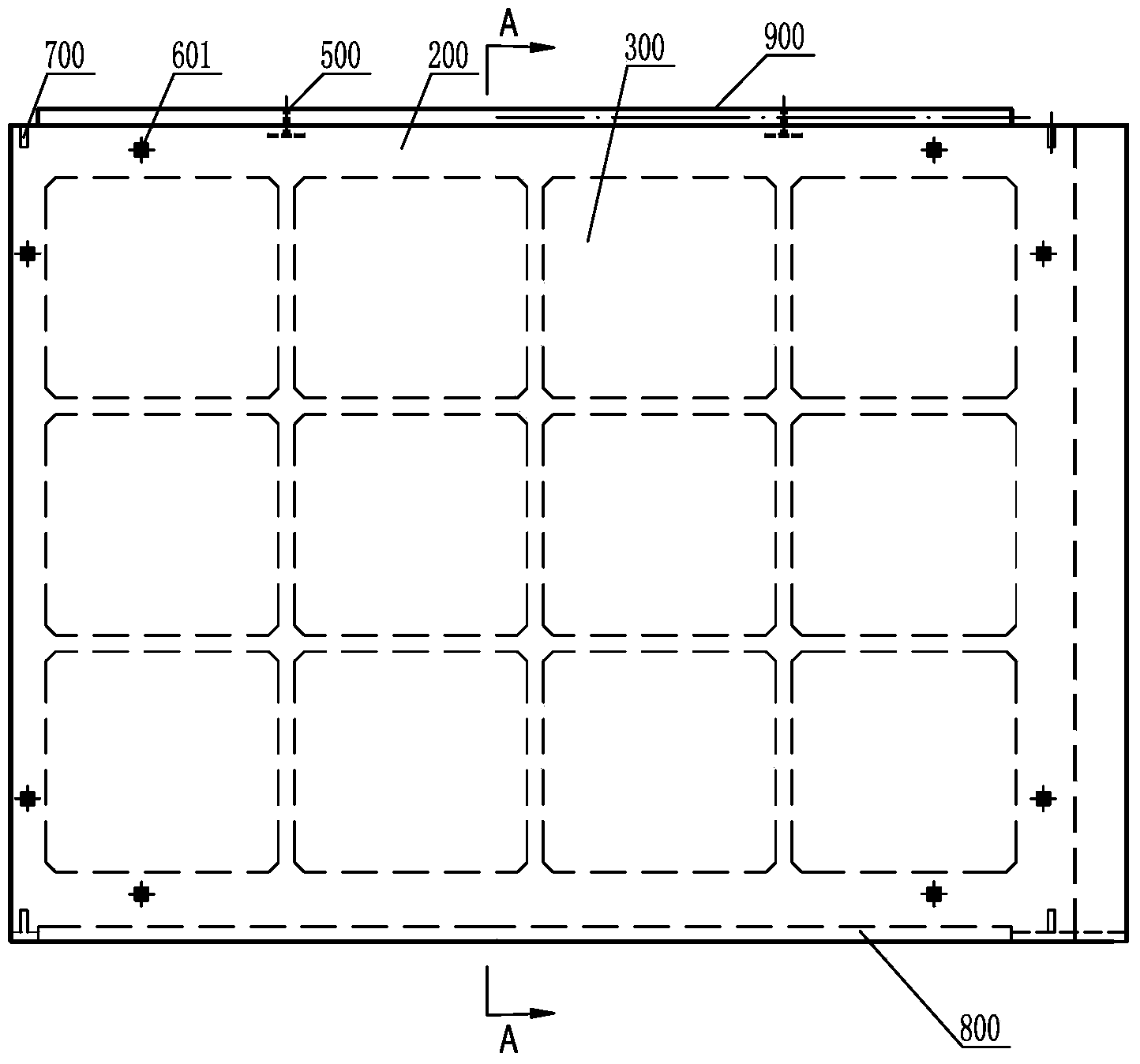

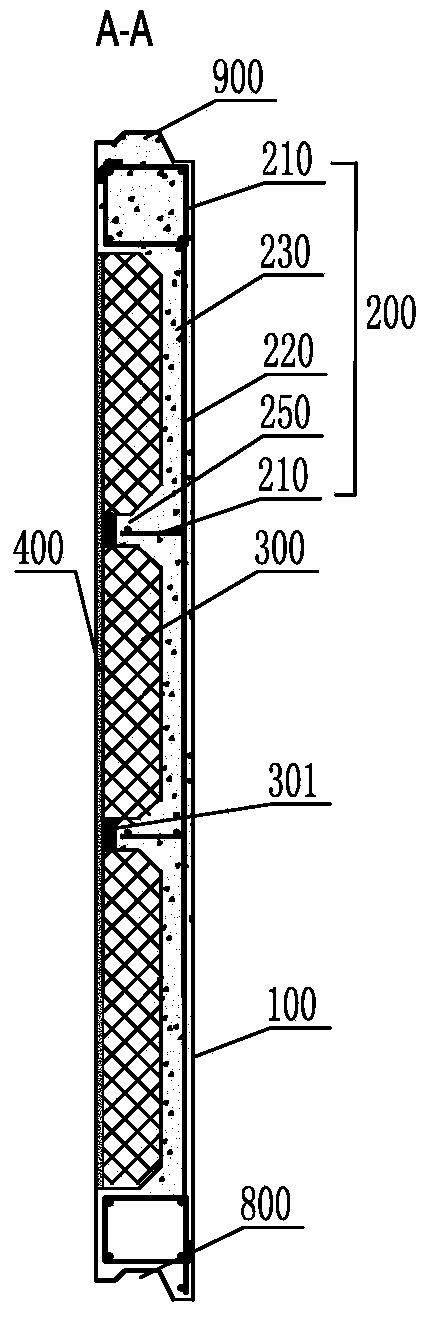

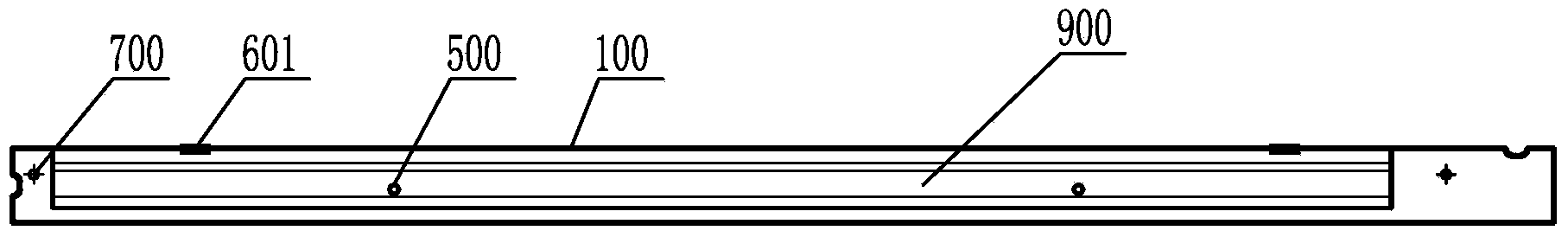

[0047] Embodiment 1, as Figure 1-9 As shown, an integrally prefabricated multifunctional composite exterior wall panel includes an exterior decorative layer 100 consolidated from outside to inside, a reinforced fine stone concrete structure layer 200, a lightweight heat insulation layer 300 and an interior Decorative layer 400 ; the reinforced fine stone concrete structure layer 200 is filled into the lightweight heat insulation layer 300 to form a slab rib 250 .

[0048] Such as Figure 1-9 As shown, the reinforced fine stone concrete structure layer 200 mainly plays the role of supporting skeleton. The exterior decoration layer 100 and the interior decoration layer 400 are used for indoor and outdoor decoration. The lightweight heat insulation layer 300 is used for heat insulation and noise reduction.

[0049] From the inside to the outside, the innermost part of the overall prefabricated multifunctional composite exterior wall panel of the present invention is the inter...

Embodiment 2

[0065] Embodiment 2, as Figure 12 Shown is the structural drawing of the overall prefabricated composite exterior wall. It is formed by arranging up, down, left, and right sides of the outer wall panels of Embodiment 1, Figure 12 Shown in is the individual exterior wall panel structures on the same level. The exterior wall panel 1 is shown as a windowless exterior wall panel, the exterior wall panel 2 is an exterior wall panel with doors and windows, and the exterior wall panel 3 is an exterior wall panel with windows. Each of the exterior wall panels is provided with a connection mechanism connected to the main force-bearing member 5, and the rear part of the connection mechanism is pre-embedded in the reinforced fine stone concrete structure layer 200 of the exterior wall panel; The wall panels are sealed and connected by telescopic seals.

[0066] The specific structure of the exterior wall panels is shown in Embodiment 1, and will not be repeated here.

[0067] Such as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com