H-shaped tower column inner force adjustable temporary cross supporting structure and construction method thereof

A construction method and tower column technology, applied in the erection/assembly of bridges, bridges, buildings, etc., can solve the problems of difficulty in demolition work, difficulty in adjusting jacking thrust, and delay in construction period, so as to reduce the workload of high-altitude welding and reduce high-altitude operations Risk, the effect of speeding up the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

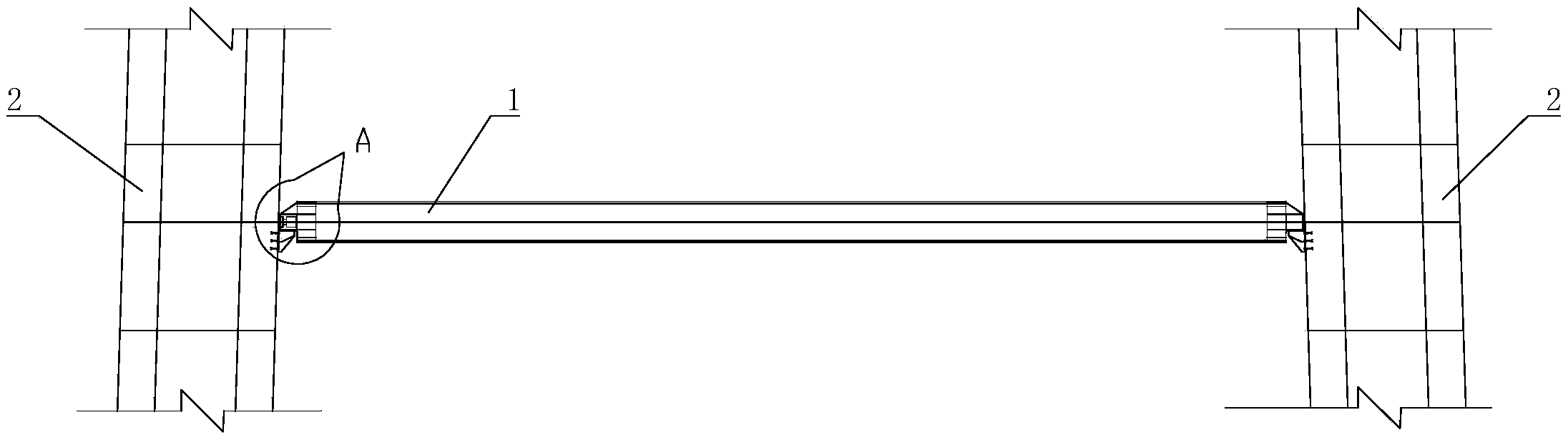

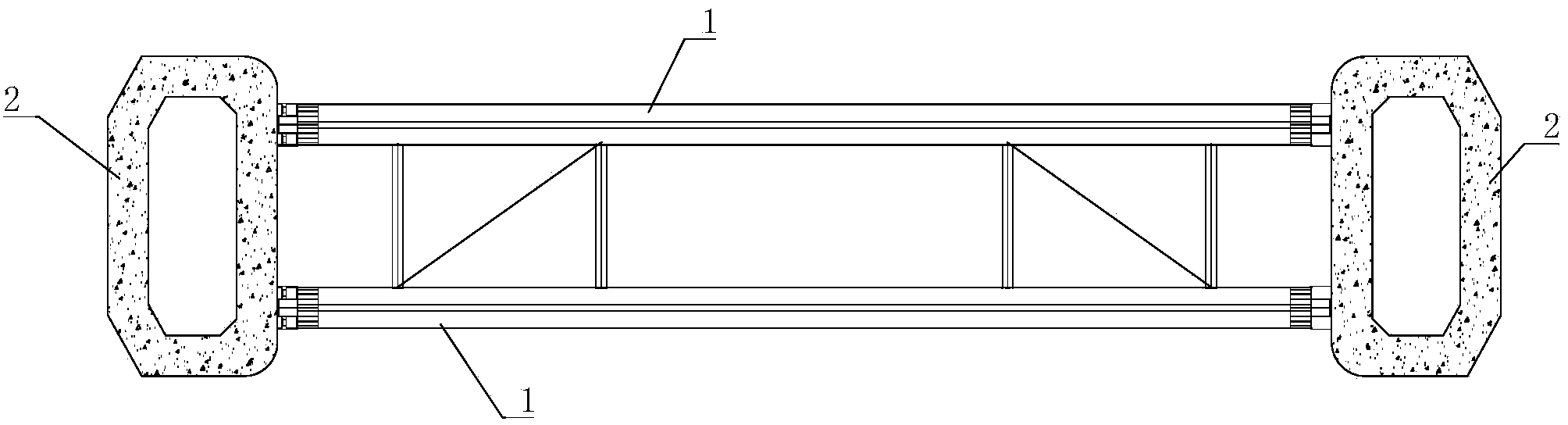

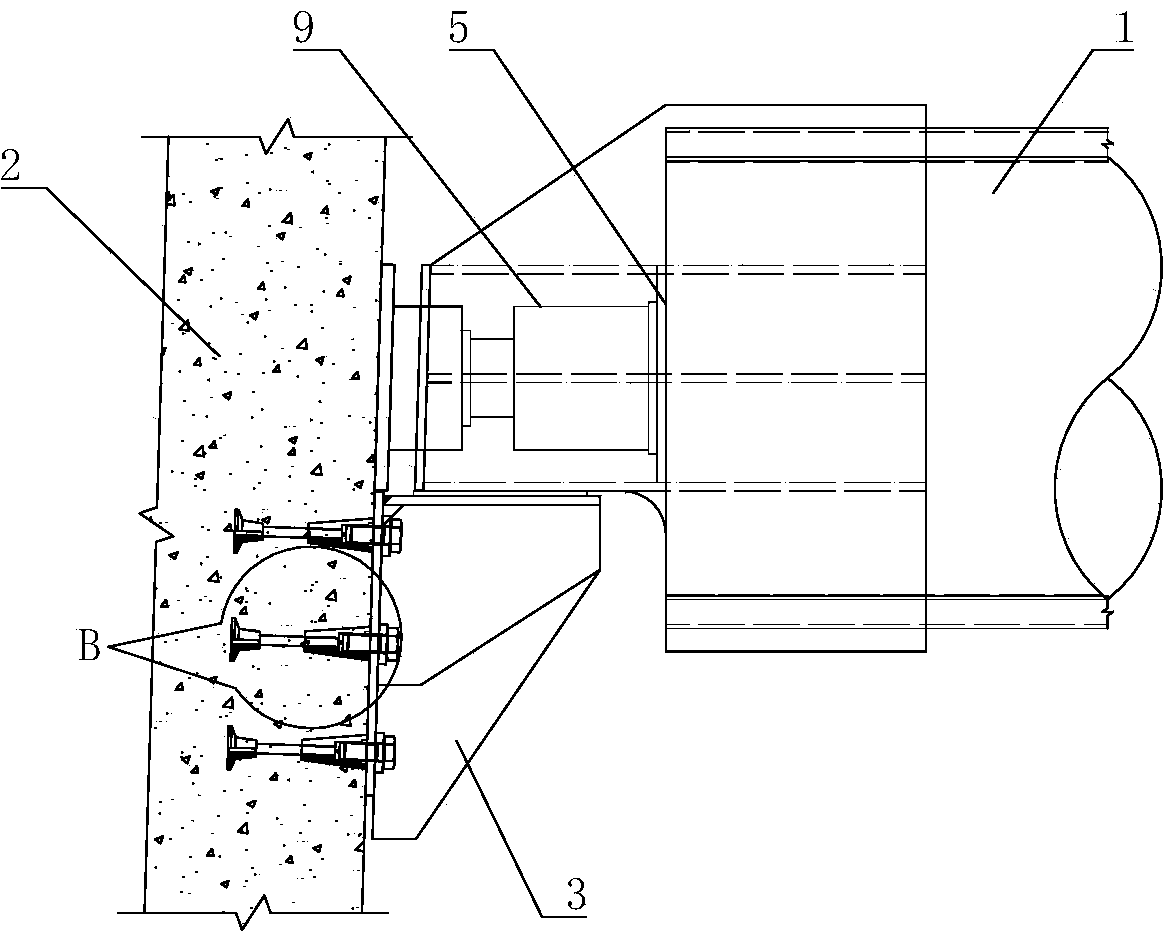

[0034] like Figure 1 to Figure 5 The temporary brace structure with adjustable internal force of the H-shaped tower column shown includes a brace 1 and corbels 3 respectively fixed on the tower columns 2 on both sides. The brace 1 is carried on the corbel 3, and the brace 1 includes a The abutment end where the tower column 2 on one side abuts and the push end located at the opposite end of the abutment end, a copy pad is inserted in the movable place between the push end and the tower column 2 on the other side, which is a copy pad in this embodiment The steel plate (not shown in the figure), the pushing end is provided with a pushing part 5, and the cross brace 1 is displaced to the abutting end after the pushing part 5 receives the pushing force.

[0035] Preferably, the pushing end is a stepped shaft structure, the shaft head of the stepped shaft structure is mounted on the corbel 3 , and the shaft shoulder of the stepped shaft structure constitutes the pushing portion 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com