Treatment process of diketene distillation residues

A technology of diketene refining and processing technology, applied in the chemical industry, can solve the problems of low extraction utilization rate, incomplete decomposition, easy to cause pollution, etc., and achieve the effects of long fermentation time, improved efficiency and high utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A. Diketene rectification residue and waste liquid are mixed according to the ratio of 1:1.5, and fly ash and water are added to the mixture. According to the mass ratio, the ratio of mixture to fly ash and water is 1:1:3. After mixing, stir for 25 minutes , forming a slurry;

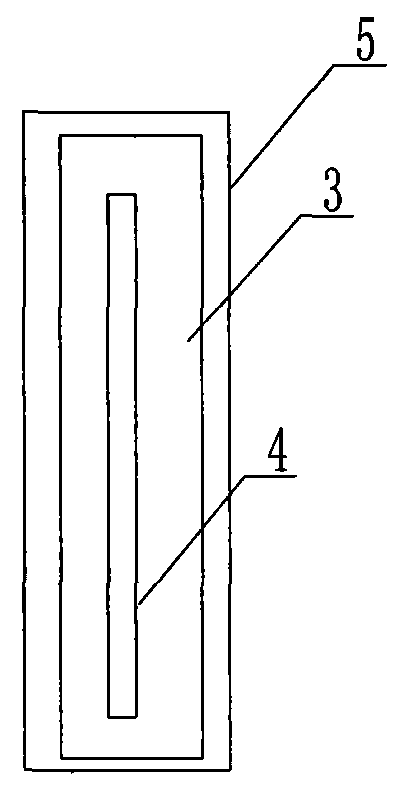

[0043] B. Put the mixed slurry into the distillation tank, and under the action of 20Hz ultrasonic waves, heat it to 35-40°C under the condition of 0.12MPa for distillation. The distilled gas passes through the pipeline and condensing device and is stored in the receiving tank , the pipeline 1 is a 3-fold elbow, the heating and purification filter 2 is 4, and the temperature of the heating and purification filter 2 is 57° C. during work; the fly ash in the heating and purification filter 2 can be recovered after working Add in step A and mix with the mixture; the heating and purification filter sheet 2 includes a shell 5 with a through hole, the fly ash wrapped in non-woven fabric is the fly ash ...

Embodiment 2

[0049] Ultrasonic wave is not used during distillation in step B, all the other are the same as embodiment 1, the acetone purity that reclaims reaches 98.9%, is that efficiency is obviously lower than embodiment 1 about 30%.

Embodiment 3

[0051] Purify the filter disk and ultrasonic wave without heating, the rest is the same as in Example 1, and the purity of recovered acetone is lower, reaching 95%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com