Threshing cylinder of harvester

A technology for threshing drums and harvesters, which is applied in threshing equipment, agricultural machinery and implements, applications, etc., can solve problems such as grain overflow, and achieve the effects of shortened overall length, compact structure, and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

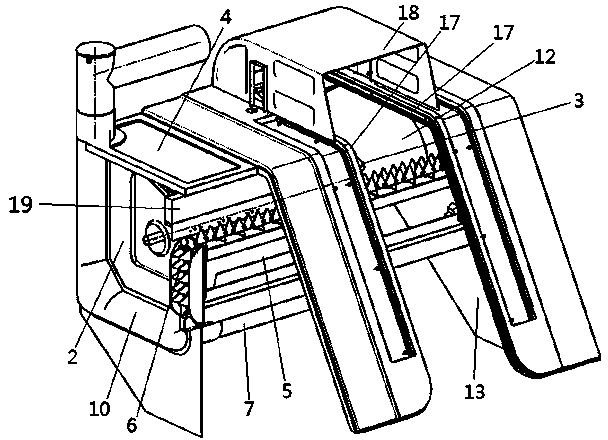

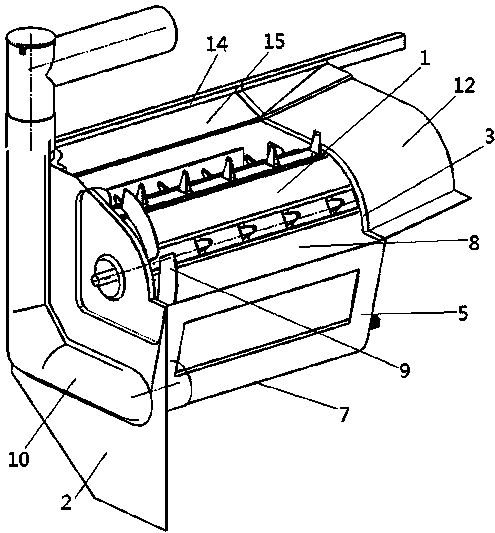

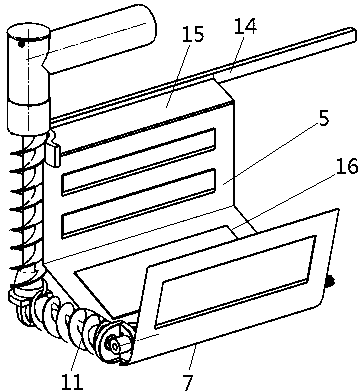

[0026] Such as Figure 1-4 As shown, the harvester threshing drum includes a threshing drum body 1 and a drum box body, and the drum box body includes a side guard plate 2 , a middle partition plate 3 , an upper cover plate 4 and a drum box bottom plate 5 .

[0027] Wherein, the middle part of roller box bottom plate 5 is bent downwards, as Figure 4 As shown, the front and rear sides of the roller case bottom plate 5 form baffles respectively, and the tops of the front and rear side baffles of the roller case bottom plate 5 are open, and the upper cover plate 4 is arranged on the open top of the roller case bottom plate 5, and the top of the roller case bottom plate 5 The front side apron stretches towards the clamping conveyor chain 6 . The bottom of the roller box bottom plate 5 forms an arc groove 7 close to the front side baffl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com