hydraulic camshaft adjuster

A camshaft adjuster and hydraulic technology, which is applied in the direction of machines/engines, valve devices, mechanical equipment, etc., can solve the leaking of the hydraulic camshaft adjuster, the difficulty of adjusting the hydraulic camshaft adjuster, and the limitation of functional adjustment speed, etc. problems, achieve high adjustment force and adjustment torque, improve efficiency, and increase friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] specific implementation plan

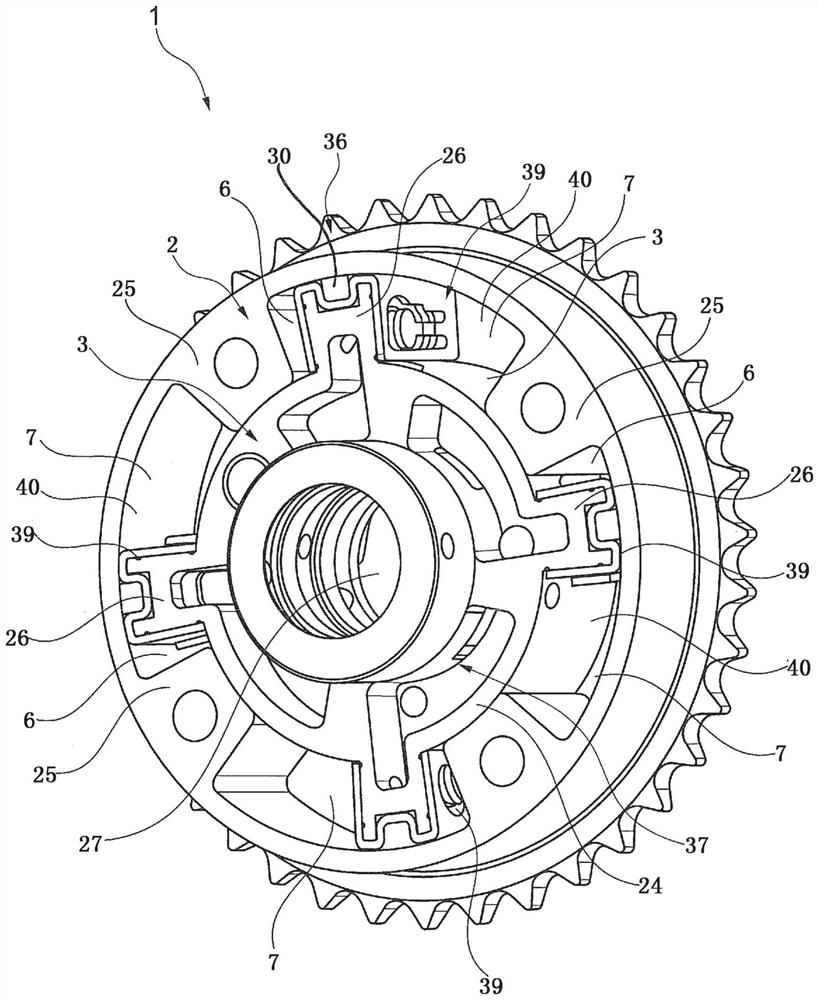

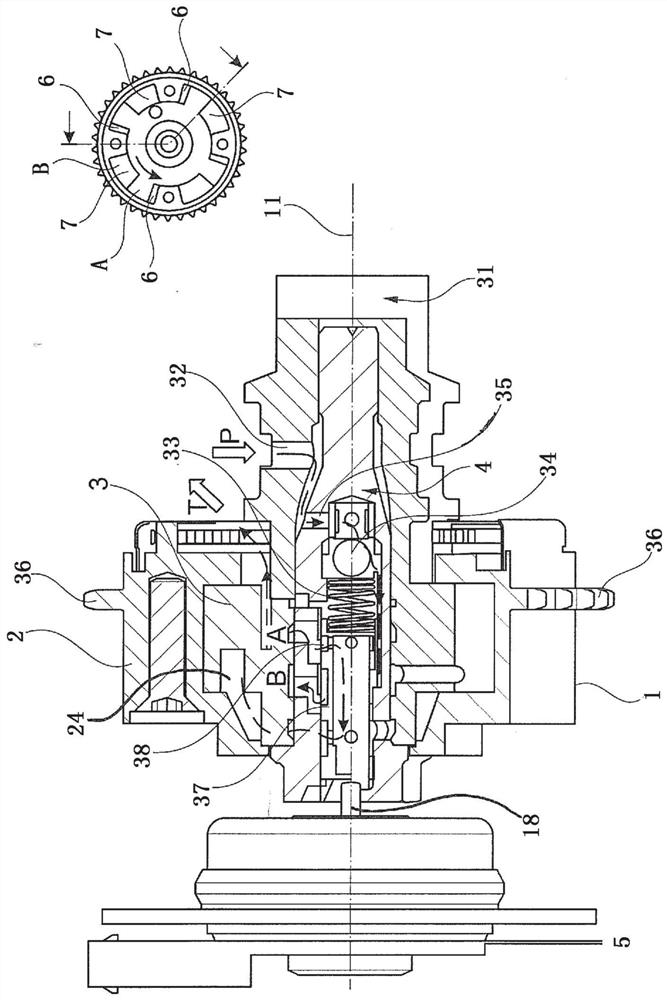

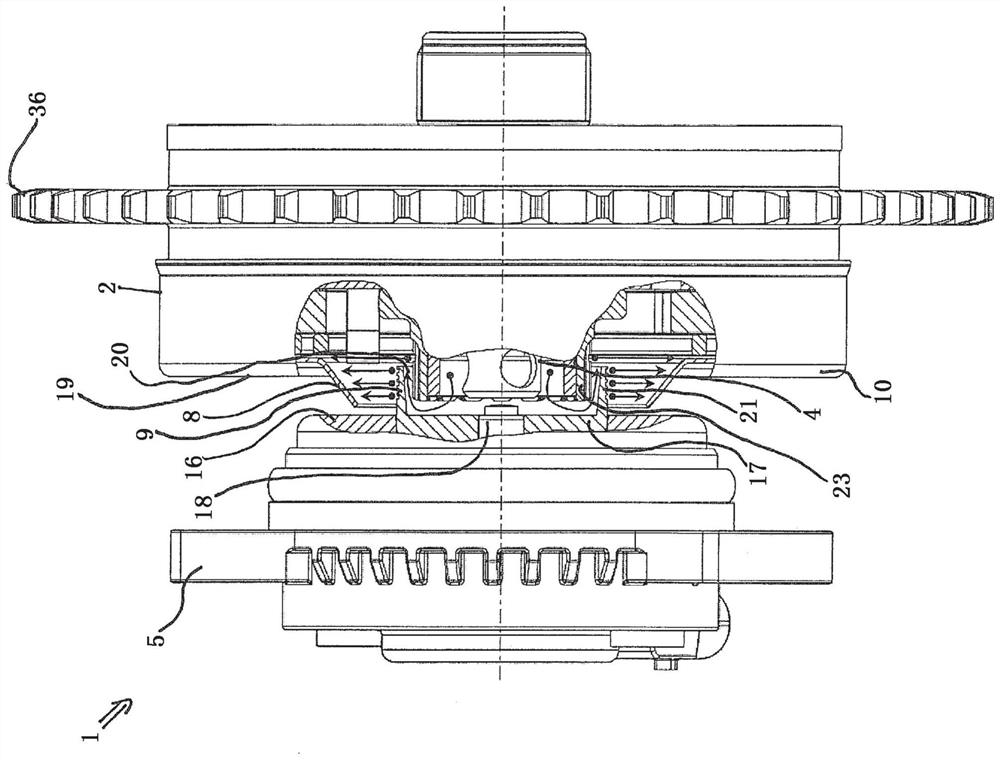

[0028] figure 1 A hydraulic camshaft adjuster 1 for adjusting the valve timing of an internal combustion engine is shown. The hydraulic camshaft adjuster 1 has a stator 2 and a rotor 3 . In this case, rotor 3 and stator 2 are arranged centrally about a common central axis 11 . The rotor 3 has a central opening 27 in which is arranged a central valve 4 for hydraulically controlling the working chambers 6 , 7 of the hydraulic camshaft adjuster 1 . Channels 37 , 38 are formed in stator 2 and / or rotor 3 for conveying or discharging hydraulic oil 12 into working chambers 6 , 7 . An annular space 40 is formed between the stator 2 and the rotor 3 . The stator 2 has inwardly protruding webs 25 in the radial direction, which delimit the individual pressure chambers of the hydraulic camshaft adjuster 1 . Outwardly protruding vanes 26 are formed on the rotor 3 in the radial direction and divide the individual pressure chambers into a first worki...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com