Preparation method for viscosity index improver

A viscosity index and improver technology, which is applied in the field of preparation of viscosity index improvers, can solve problems such as unsatisfactory and difficult to control product quality, and achieve the effects of mild conditions, environmental friendliness, and simple process operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

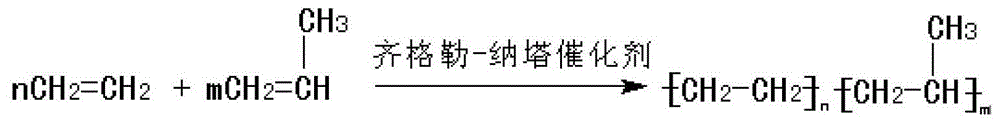

Method used

Image

Examples

Embodiment 1

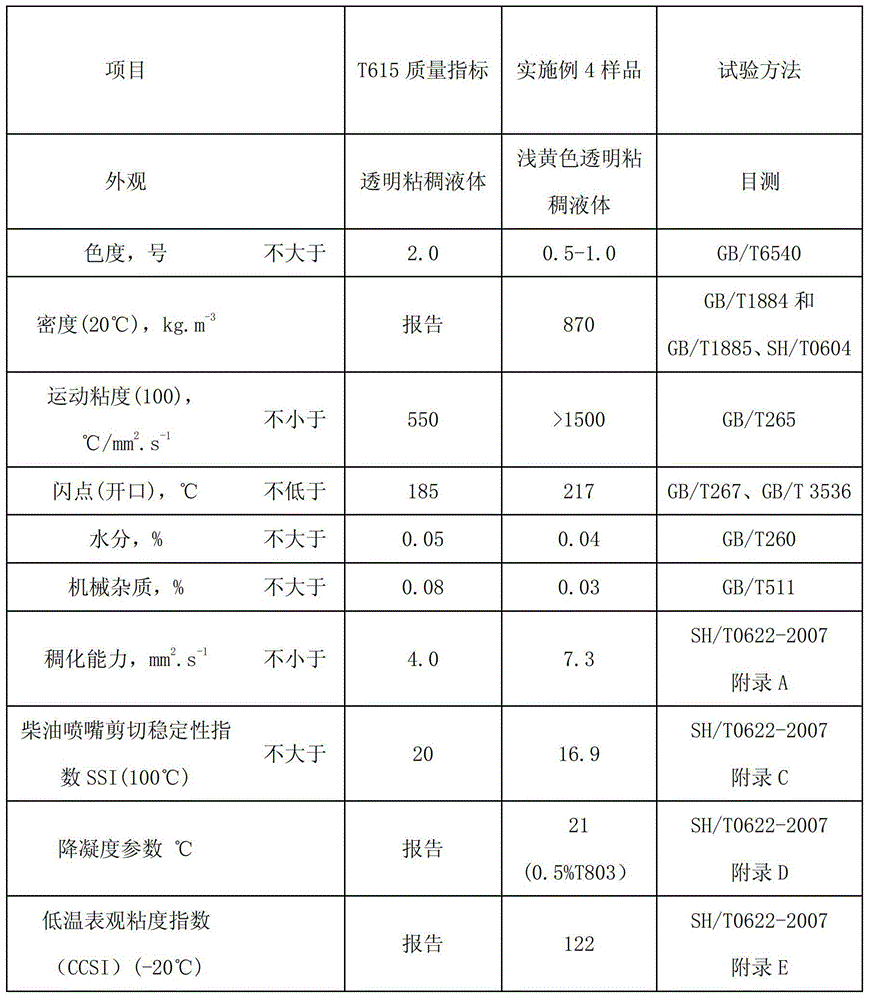

[0022] Add 86g of base oil into a 200ml glass container equipped with a stirrer, thermometer, heating mantle and air pipe, start stirring, then add 0.05g of octadecylamine, raise the temperature to 30°C, and then add 14g of ethylene propylene cut into small pieces glue. Open the gas valve, pass nitrogen protection to the reactor, continue to heat up to 120°C, react for 4 hours, close the gas valve, add 0.5g of 30% hydrogen peroxide, open the gas valve, and keep the temperature to continue the reaction for 60 minutes. After the reaction is over, stop ventilation, cool down and discharge. The product is analyzed and tested according to the petrochemical SH / T0622-2007 standard, and the product meets the T615 quality index. Its thickening capacity is 6.5mm 2 ·s -1 , Diesel nozzle shear stability index SSI (100 ℃) is 17.1.

Embodiment 2

[0024] Add 127g of base oil into a 250ml glass container equipped with a stirrer, thermometer, heating mantle and air pipe, start stirring, then add 1g of octadecylamine, raise the temperature to 40°C, and then add 22g of ethylene-propylene rubber cut into small pieces . Open the gas valve, pass nitrogen protection to the reactor, continue to heat up to 110°C, react for 5 hours, close the gas valve, add 2g of 30% hydrogen peroxide, open the gas valve, keep the temperature and continue the reaction for 30 minutes. After the reaction is over, stop ventilation, cool down and discharge. After the reaction is over, stop ventilation, cool down and discharge. The product is analyzed and tested according to the petrochemical SH / T0622-2007 standard, and the product meets the T615 quality index. Its thickening capacity is 7.7mm 2 ·s -1 , Diesel nozzle shear stability index SSI (100 ℃) is 18.4.

Embodiment 3

[0026] Add 680g of base oil into a 1000ml glass container equipped with a stirrer, thermometer, heating mantle and air pipe, start stirring, then add 20g of octadecylamine, raise the temperature to 40°C, and then add 120g of ethylene-propylene rubber cut into small pieces . Open the gas valve, pass nitrogen protection to the reactor, continue to heat up to 110°C, react for 4 hours, close the gas valve, add 20g of 30% hydrogen peroxide, open the gas valve, and keep the temperature to continue the reaction for 40 minutes. After the reaction is over, stop ventilation, cool down and discharge. The product is analyzed and tested according to the petrochemical SH / T0622-2007 standard, and the product meets the T615 quality index. Its thickening capacity is 8.2mm 2 ·s -1 , Diesel nozzle shear stability index SSI (100 ℃) is 18.9.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickening ability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com