Biological combined reactor used for printing and dyeing waste water processing, device and method

A combined reactor and printing and dyeing wastewater technology, applied in the textile industry wastewater treatment, chemical instruments and methods, water/sewage multi-stage treatment, etc. The difficulty of treatment of printing and dyeing wastewater, the inability of biological treatment methods to achieve the treatment effect, etc., to achieve the effects of low infrastructure and operation costs, good effluent quality, and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0079] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

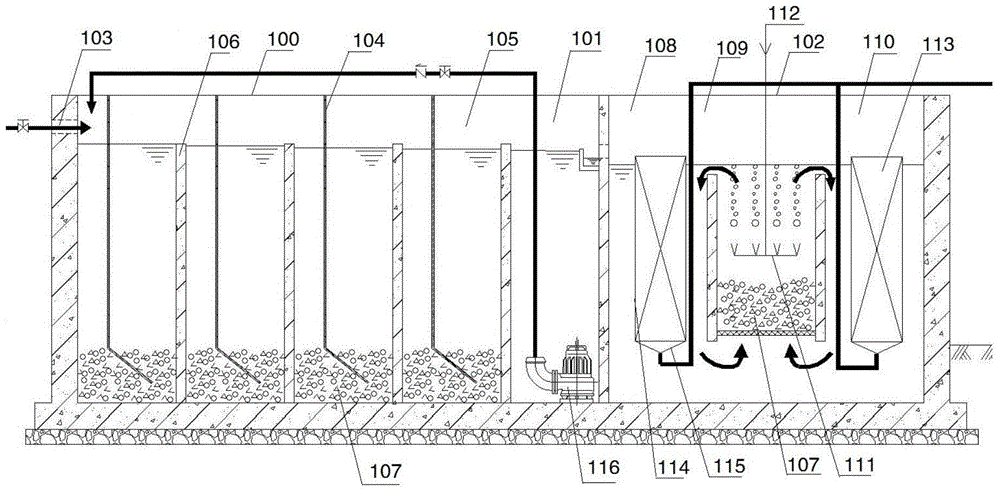

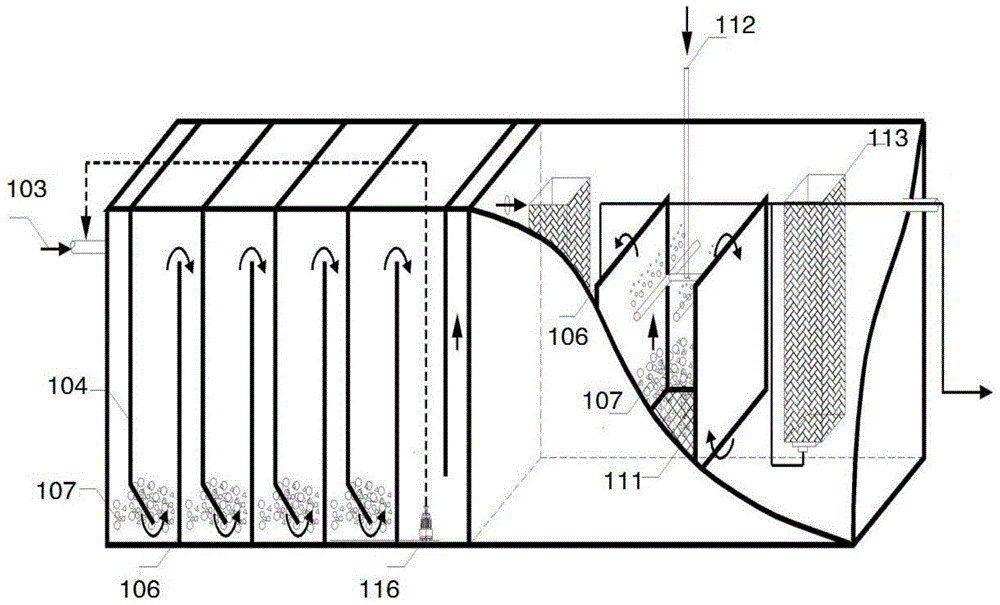

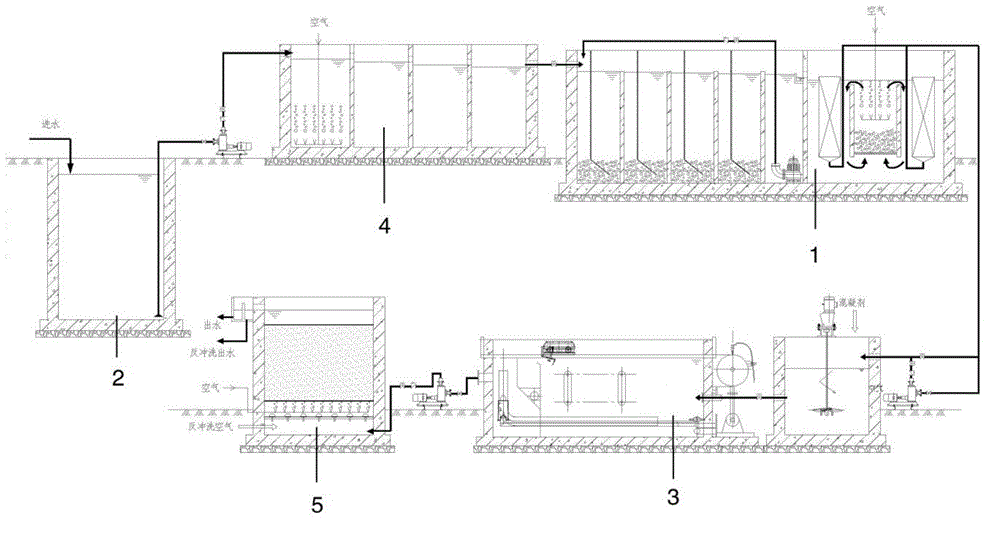

[0080] see figure 1 and figure 2 ; figure 1 It is a structural schematic diagram of a biological combination reactor 1 for printing and dyeing wastewater treatment in one embodiment of the present invention; figure 2 It is a three-dimensional schematic diagram of a biological combination reactor for printing and dyeing wastewater treatment in one embodiment of the present invention. The thick black arrows in the figure represent the direction of water flow. The biocombination reactor 1 includes an anaerobic baffle reaction zone 100, an anaerobic reflux chamber 101 and an aerobic dynamic reaction zone 102; the water inlet 103 of the biocombination reactor 1 is located in the anaerobic baffle reaction zone 100; The water outlet of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com