High-efficiency energy-saving heat-shrinkable tube shrinking machine for assembly line

A high-efficiency energy-saving, heat-shrinkable tube technology, which is applied to conveyors, tubular objects, household appliances, etc., can solve problems such as uneven heating, lack of energy saving and economy, and high heat loss, so as to protect health and improve work efficiency , to reduce the effect of the operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

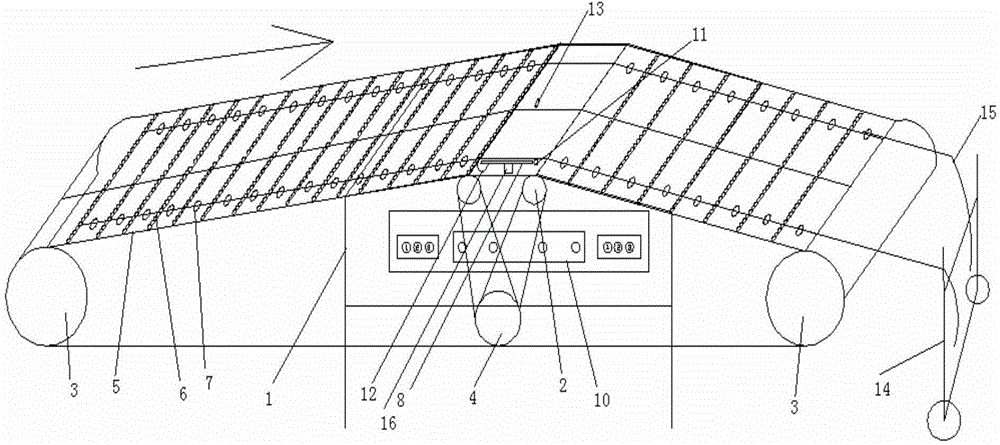

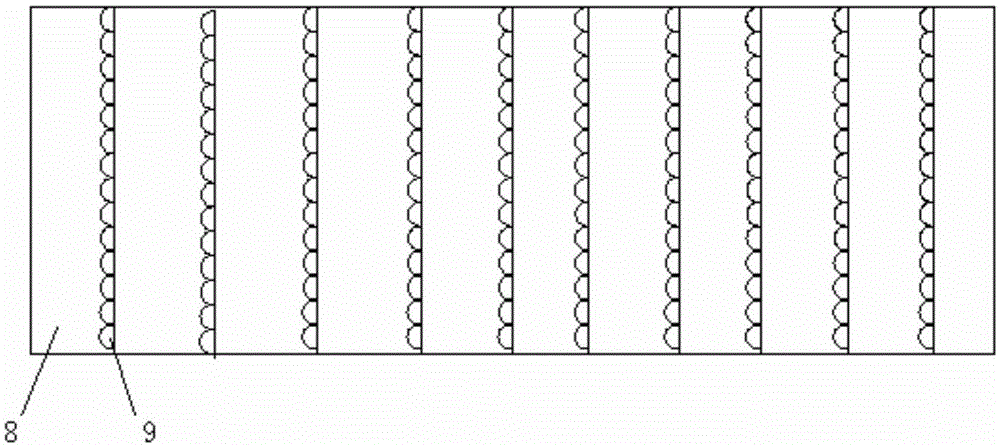

[0019] Such as figure 1 , 2 , 3, an assembly line high-efficiency energy-saving heat-shrinkable tube shrinking machine includes a trapezoidal support 1, a rotating roller 2 is installed above the trapezoidal support 1, and a rotating shaft 3 is respectively placed on the left and right sides of the trapezoidal support 1. The rotating shaft 3 and the motor 4 connection, a conveyor belt 5 is connected to the rotating shaft 3 and the rotating roller 2, heat-shrinkable tube branches 6 are evenly distributed on the conveyor belt 5, and two rows of wire harness ring clips are respectively arranged on the conveyor belt 5 near the edges of both sides Slot 7, the wire harness ring slot 7 of each column is on the same straight line, a heat shield 8 is fixed below the conveyor belt 5 above the trapezoidal support 1, and electric heating wires 9 are evenly distributed on the heat shield 8, and the electric heating wire 9 is connected with a heating wire switch 10, a strip fan 11 is insta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com