A three-dimensional digital floor mold production method

A production method, three-dimensional digital technology, applied in the direction of manufacturing tools, ceramic molding machines, etc., to achieve the effect of low equipment and site requirements, improve production efficiency, ensure surface smoothness and seam accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Example 1 Production of three-dimensional digital ground mold for building curtain wall in Tianjin Port

[0041] 1) Use RHINO software on the computer to perform overall three-dimensional modeling of the Tianjin Port building curtain wall to form an overall model, such as figure 1 Shown.

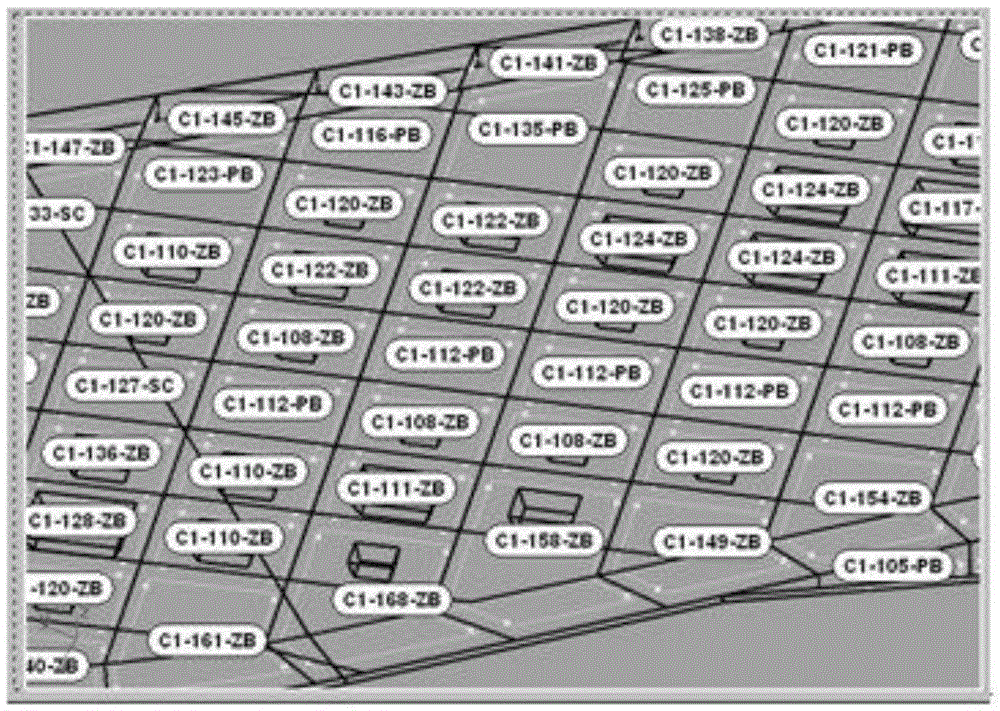

[0042] 2) Divide the overall model into a number of individual modules with an overall drop of less than 1600mm, and each individual module uses 3D digital software to perform 3D modeling again, using the segmented datum plane as the horizontal plane, select the origin, and establish 3D coordinates and Mark the space coordinates of key points, such as figure 2 As shown, the origin is the point closest to the corners of the monomer modules on the horizontal plane; the key points refer to the corners of the individual modules, and the edges of the individual modules are divided into equal points on the ground. The line point and the space base point of the line.

[0043] 3) Obtain the conto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com