Self-threading tape positioning device of soft tape sleeve in outlet of cold rolling and continuous annealing unit and positioning method thereof

A continuous annealing unit and automatic strip threading technology, which is applied in the direction of rolling mill control devices, metal rolling, metal rolling, etc., can solve the problems of strip head indentation, difficulty in electrical control, secondary damage to strip steel, etc., to reduce indentation , Simple and efficient automatic belt threading method, the effect of saving materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

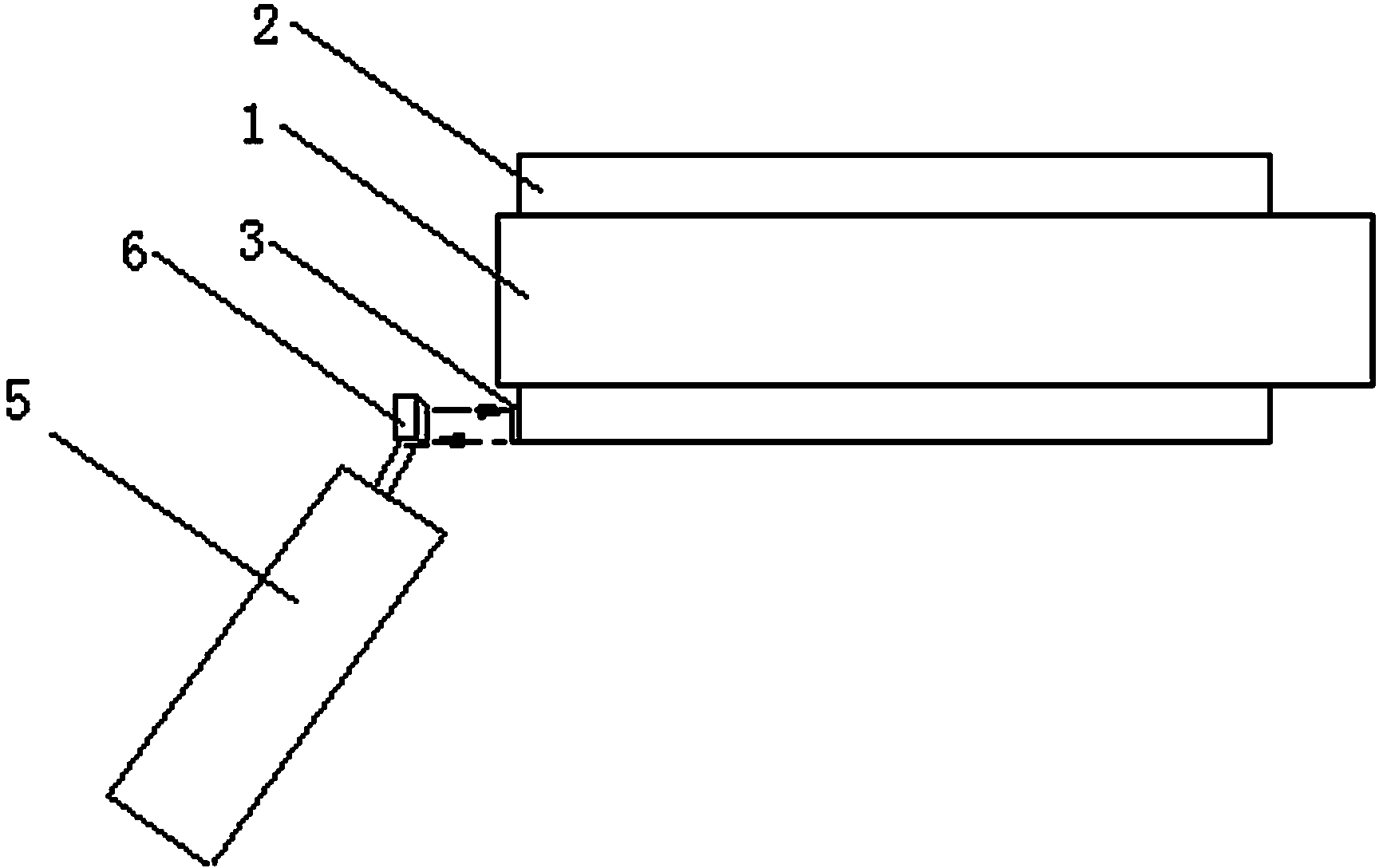

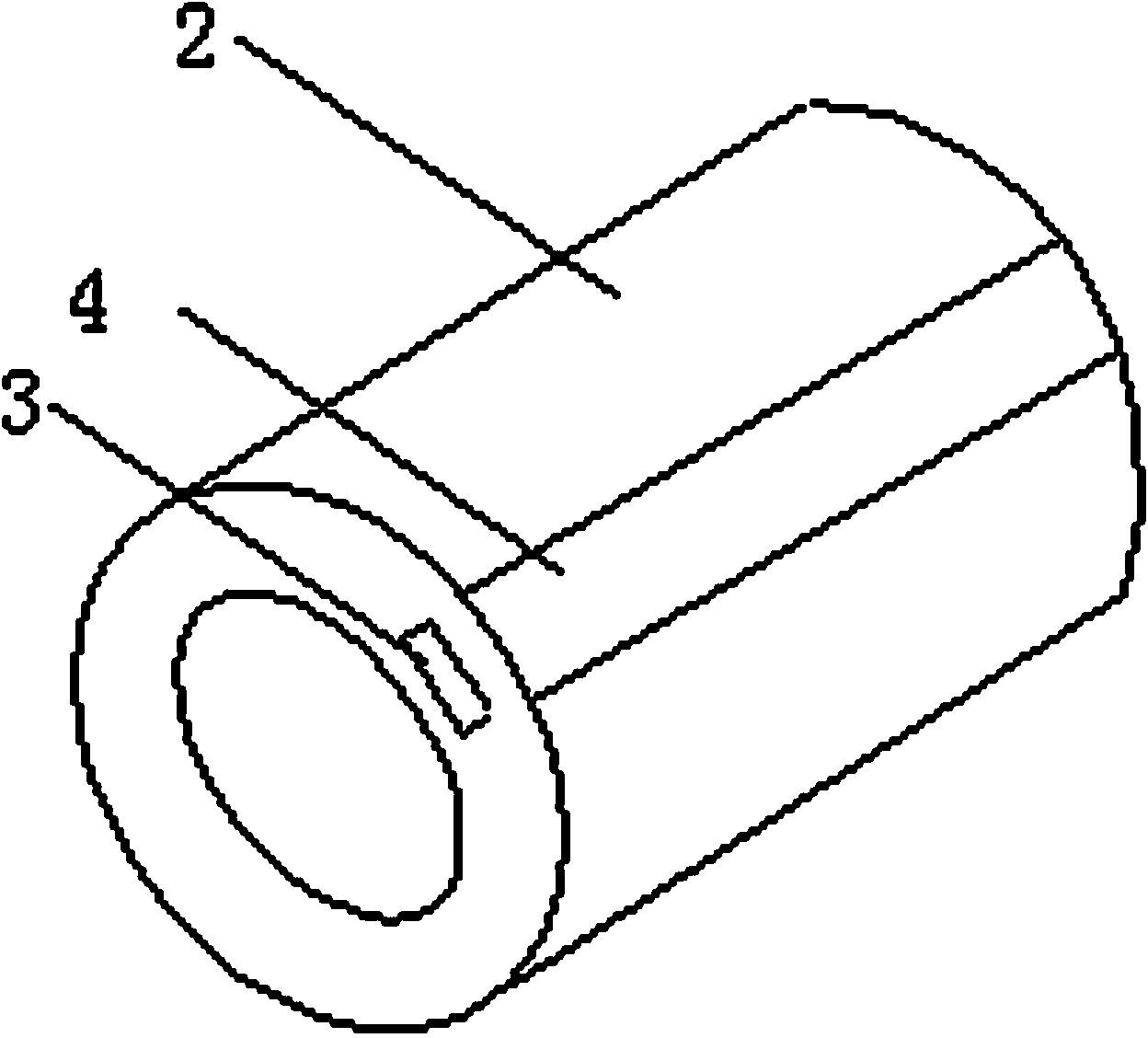

[0018] Such as Figure 1-4 As shown, this specific embodiment adopts the following technical scheme: its device includes a mandrel 1, a soft belt sleeve 2, a reflective paper 3, a soft area 4, an outer support arm 5 and a photoelectric cell 6, and the outer side of the mandrel 1 is sleeved There is a soft belt sleeve 2, and the soft belt sleeve 2 is provided with a soft area 4 from front to back, and the front end of the soft belt sleeve 2 corresponding to the soft area 4 is provided with a reflective paper 3, and the operation side of the soft belt sleeve 2 A photoelectric cell 6 is installed on the outer support arm 5 .

[0019] The flexible tape sleeve 2 is sleeved on the outside of the mandrel 1, and the mandrel 1 is driven by a coiler, and the coiler includes a tape head initial positioning system 8, a coiler motor controller 9 and a coiler Take machine motor 10.

[0020] The photoelectric cell 6 is connected with one end of the head initial positioning system 8, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com