Preparation method of coal slime flotation accelerant and coal slime flotation method

A technology of coal slime flotation and accelerator, applied in flotation, solid separation, etc., can solve the problems of high ash content of clean coal, high synthesis cost, complex synthesis process, etc., to reduce interfacial tension, increase clean coal yield, The effect of improving dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Alkylphenol polyoxyethylene ether (the degree of polymerization of ethylene oxide is n=4-12) and sulfamic acid are used as raw materials, the molar ratio of the two is 1:0.5, and the reaction temperature is controlled at 70°C. During the synthesis process, it is necessary Stir continuously, and the reaction time is 30 minutes. After the reaction is completed, it can be lowered to normal temperature. The conversion rate of alkylphenol polyoxyethylene ether is 40.86%. The products obtained after the reaction include alkylphenol polyoxyethylene ether and synthetic Alkylphenol polyoxyethylene ether ammonium sulfate, and coexist in a molar ratio of 1.45:1.

[0033] In the flotation of coal slime, the amount of hydrocarbon oil collector is reduced by 23.71wt%, and the accelerant added accounts for 0.9wt% of hydrocarbon oil.

Embodiment 2

[0035] Alkylphenol polyoxyethylene ether (the degree of polymerization of ethylene oxide is n=4-12) and sulfamic acid are used as raw materials, the molar ratio of the two is 1:0.55, and the reaction temperature is controlled at 80°C. During the synthesis process, it is necessary to Stir continuously, and the reaction time is 35 minutes. After the reaction, it can be lowered to normal temperature. The conversion rate of alkylphenol polyoxyethylene ether is 45.62%. The products obtained after the reaction include alkylphenol polyoxyethylene ether and synthetic Alkylphenol polyoxyethylene ether ammonium sulfate, and coexist in a molar ratio of 1.2:1.

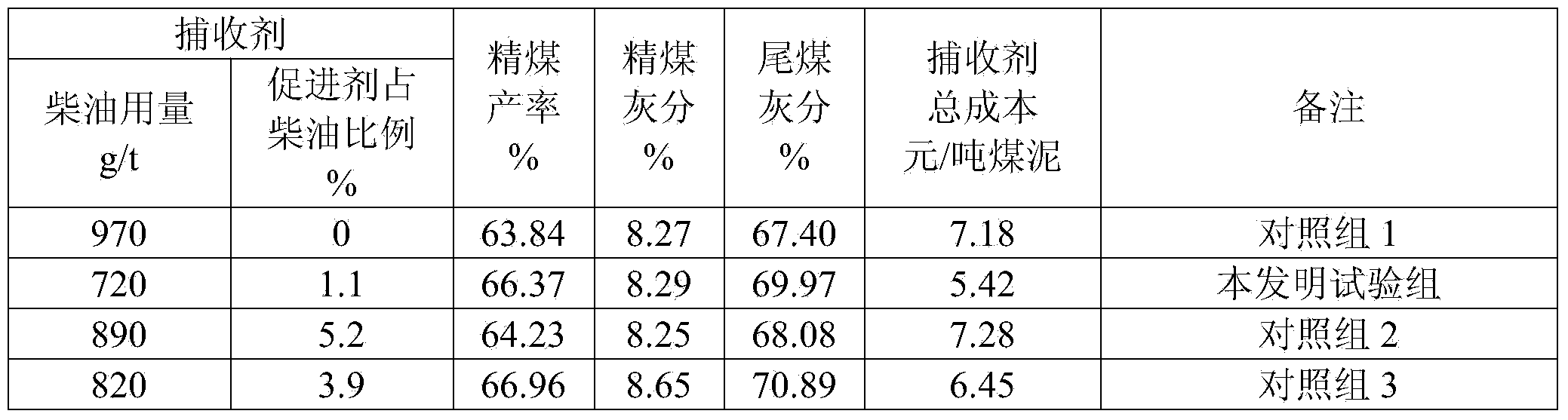

[0036] When flotation coal slime, the amount of hydrocarbon oil collector is reduced by 25.77wt%, and the accelerant added accounts for 1.1wt% of hydrocarbon oil.

Embodiment 3

[0038] Alkylphenol polyoxyethylene ether (the degree of polymerization of ethylene oxide is n=4-12) and sulfamic acid are used as raw materials, the molar ratio of the two is 1:0.6, and the reaction temperature is controlled at 90°C. During the synthesis process, it is necessary to Stir continuously, and the reaction time is 40 minutes. After the reaction is completed, it can be lowered to normal temperature. The conversion rate of alkylphenol polyoxyethylene ether is 49.21%. The products obtained after the reaction include alkylphenol polyoxyethylene ether and synthetic Alkylphenol polyoxyethylene ether ammonium sulfate, and coexist in a molar ratio of 1.03:1;

[0039] When flotation coal slime, the amount of hydrocarbon oil collector is reduced by 21.36wt%, and the accelerant added accounts for 1.5wt% of hydrocarbon oil.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com