High-efficiency pulverizer for pulverizing crops containing continuous fibers

A technology of long fiber and pulverizer, which is applied in the direction of grain processing, etc. It can solve the problems of long fiber entanglement, lower product yield, and increase the workload of the pulverizer, so as to achieve good material cutting and hammering effects, improve production efficiency, Avoid the effect of causing the machine to freeze

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing:

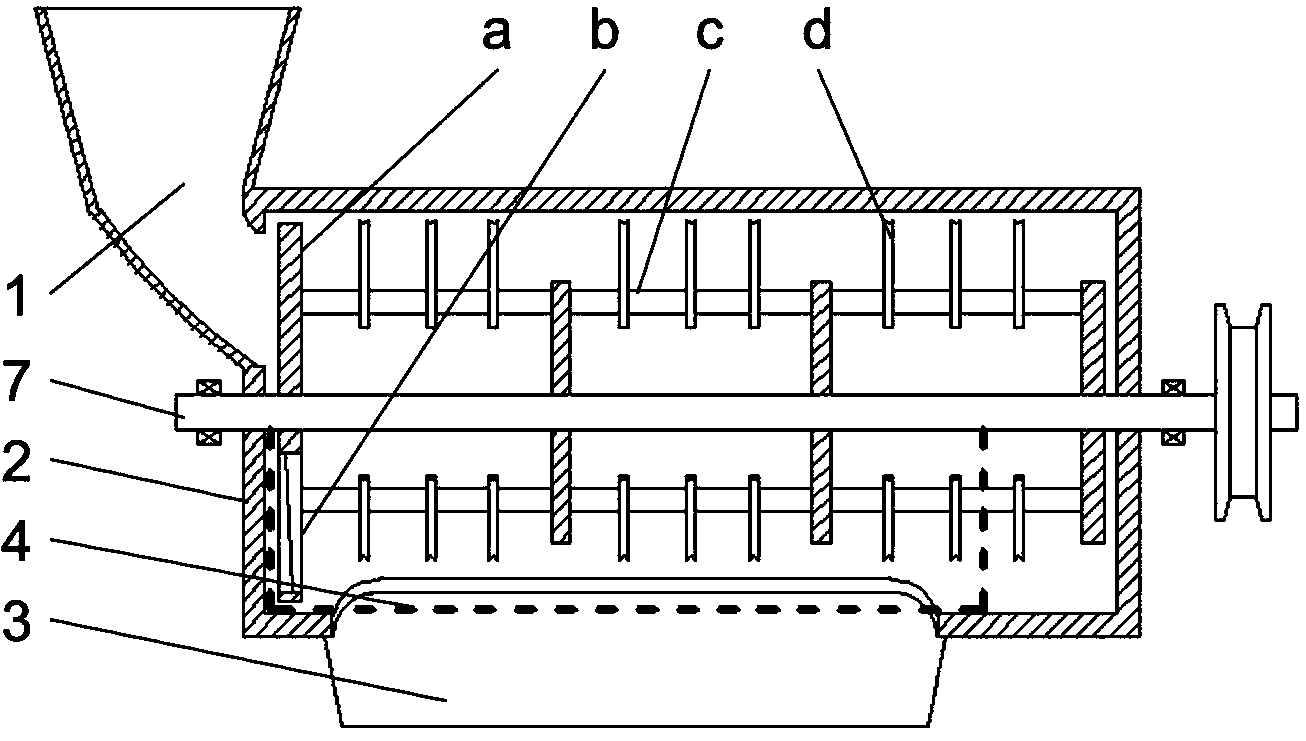

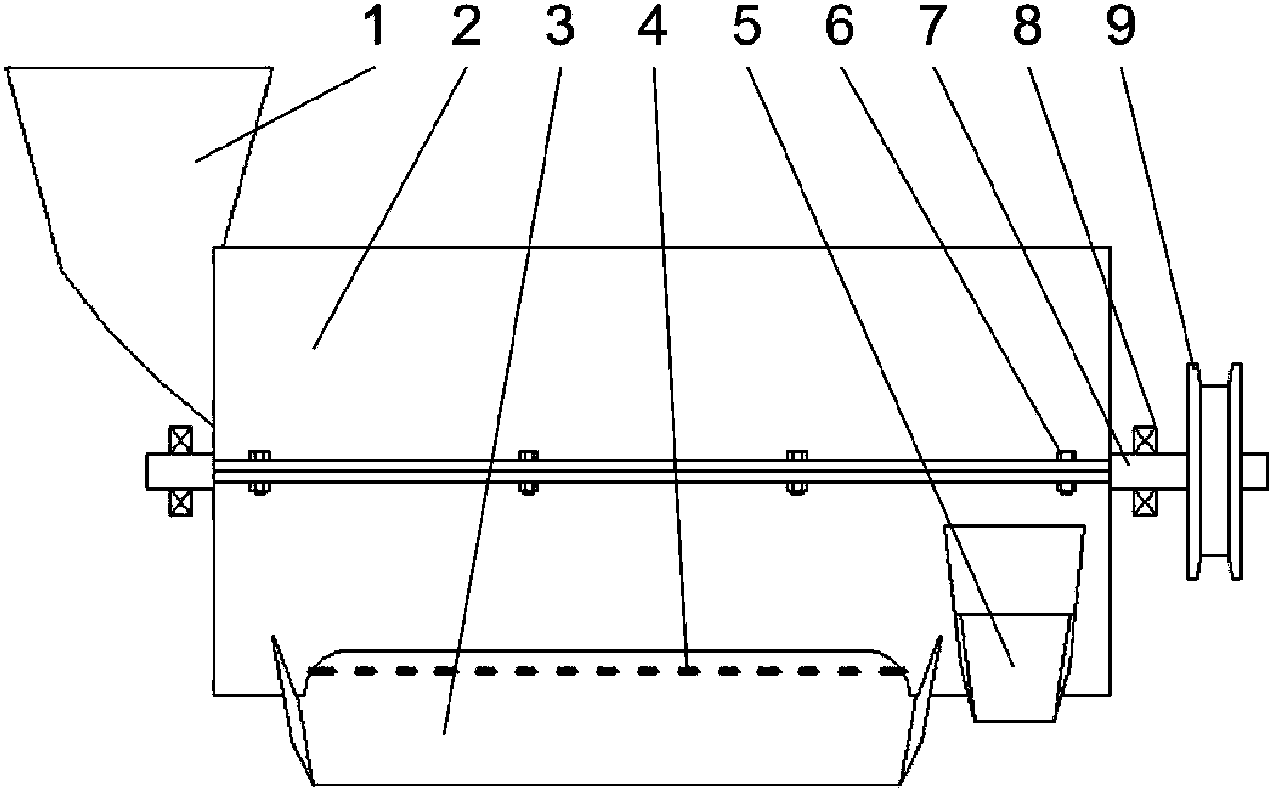

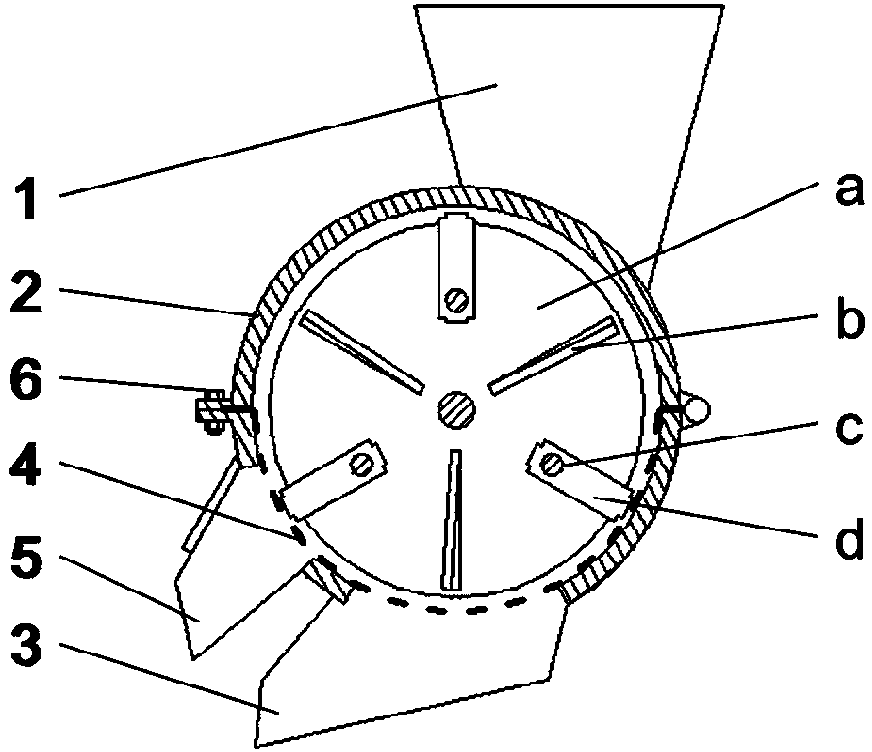

[0021] Such as figure 1 , figure 2 As shown, the high-efficiency pulverizer for crushing crops containing long fibers has a cylindrical casing (2) which is divided into an upper casing and a lower casing. The two parts are connected by a hinge on one side and screws on the other Fasten (6), and loosen the screws to open the casing. The feed inlet (1) is arranged on the left end face of the upper casing; the bottom of the lower casing is provided with a slurry outlet (3) on the left side; the side wall of the lower casing is provided with a slag outlet (5) on the right side. A 15-mesh screen (4) is arranged above the slurry outlet, and the screen is semicircular and closely attached to the inner wall of the lower casing, and its two ends are respectively clamped and fixed by the closure of the casing.

[0022] Such as figure 2 As shown, the internal rotor of the high-e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com