Polymerizable composition for optical material containing thioepoxy compound, and preparation method of optical material

A technology of thioepoxy and optical materials, which is applied in optics, optical components, instruments, etc., can solve the problems of difficult hardening, low lens quality, and increased production costs, and achieve the effects of increasing yield and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

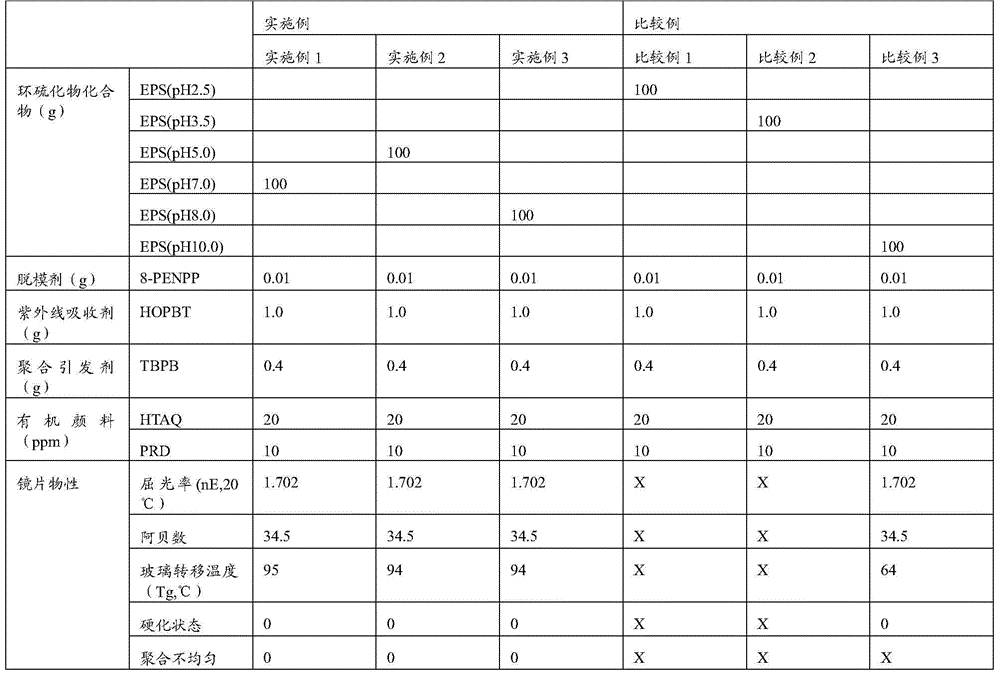

Examples

Synthetic example 1

[0041] Synthesis Example 1: Bis(3-chloro-2-hydroxylpropyl)sulfide (bis(3-chloro-2-hydroxylpropyl)sulfide) Synthesis

[0042] After adding epichlorohydrin (5563g, 60.12mol) and methanol (2500g) to a 10-liter reactor, the reaction temperature was adjusted to 6°C, and when the reaction temperature reached 6°C, caustic soda (caustic soda) (50% aq, 5g). Add NaSH.xH to another 10 L reactor 2 O (70%NaSH, 3660g, 45.75mol), methyl alcohol (1000g) and water (500g), after melting completely by stirring, slowly add hydrochloric acid dropwise, the hydrogen sulfide of generation is added to epichlorohydrin solution, obtained two ( 3-Chloro-2-hydroxypropyl) sulfide. The end point of the reaction is when the final product is confirmed by GC, epichlorohydrin and 3-chloro-2-hydroxy-propyl-1-thiol compound disappear completely, and bis(3-chloro-2-hydroxypropyl) sulfide is formed point in time. If there is 3-chloro-2-hydroxy-propyl-1-thiol, the relative content is calculated by GC, and t...

Synthetic example 2

[0043] Synthesis Example 2: Synthesis of Bis-(2,3-cyclothiopropyl)sulfide (pH2.5)

[0044] Bis(3-chloro-2-hydroxypropyl) sulfide (1072.48 g, 4.89 mol), 1300 g of toluene, and 800 g of methanol were added to a 10-liter reaction vessel, stirred, and the reaction temperature was adjusted to 30°C. When it reached 25°C, NaOH (50% aq., 783.08g, 9.78mol) was added dropwise, and the reaction temperature during the dropwise addition was carried out at 35-37°C, and the reaction was carried out while maintaining the temperature. Dropping is carried out within 1 hour, and then placed at 37°C for about 30 minutes to ferment. After the fermentation is over, add 2000g of toluene, stir for about 10 minutes, and carry out layering. The organic matter in the supernatant is washed twice with water. Remove moisture to the limit, add methanol 400g again to the organic solution with several layers, stir, add thiourea (thiourea) (1117.65g, 14.30mol) and anhydrous acetic acid (70g) at a reaction te...

Synthetic example 3

[0045] Synthesis Example 3: Synthesis of Bis-(2,3-cyclothiopropyl)sulfide (pH3.5)

[0046] Bis(3-chloro-2-hydroxypropyl) sulfide (1072.48 g, 4.89 mol), 1300 g of toluene, and 800 g of methanol were added to a 10-liter reaction vessel, stirred, and the reaction temperature was adjusted to 25°C. When it reached 25°C, NaOH (50% aq., 783.08g, 9.78mol) was added dropwise, and the reaction temperature during the dropwise addition was carried out at 35-37°C, and the reaction was carried out while maintaining the temperature. Dropping is carried out within 1 hour, and then placed at 37°C for about 30 minutes to ferment. After the fermentation is over, add 2000g of toluene, stir for about 10 minutes, and carry out layering. The organic matter in the supernatant is washed twice with water. Remove moisture to the limit, add methanol 400g again to the organic solution with several layers, stir, add thiourea (thiourea) (1117.65g, 14.30mol) and anhydrous acetic acid (70g) at a reaction te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| Abbe number | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com