Gear Pair Adjustable Speed Permanent Magnetic Coupling

A permanent magnet coupling and gear pair technology, applied in the field of mechanical transmission, can solve the problems of difficult compensation of the axial offset of the external drive device, not suitable for occasions with low power, increase the eccentricity of the coupling, etc., and achieve a simplified structure. , easy to adjust, the effect of reducing the diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

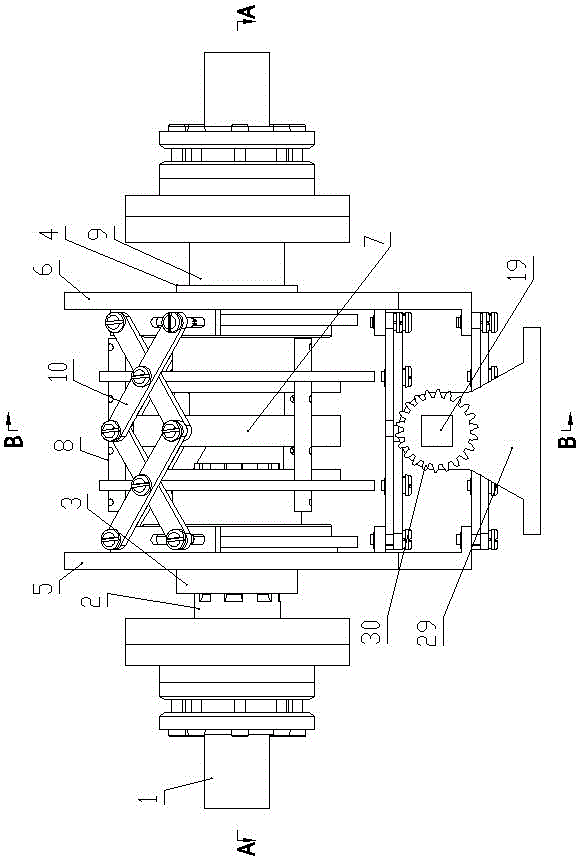

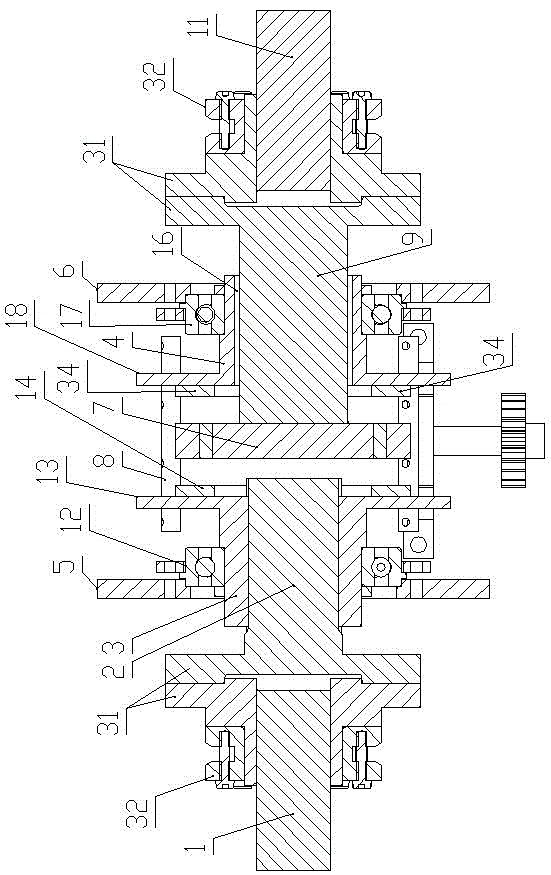

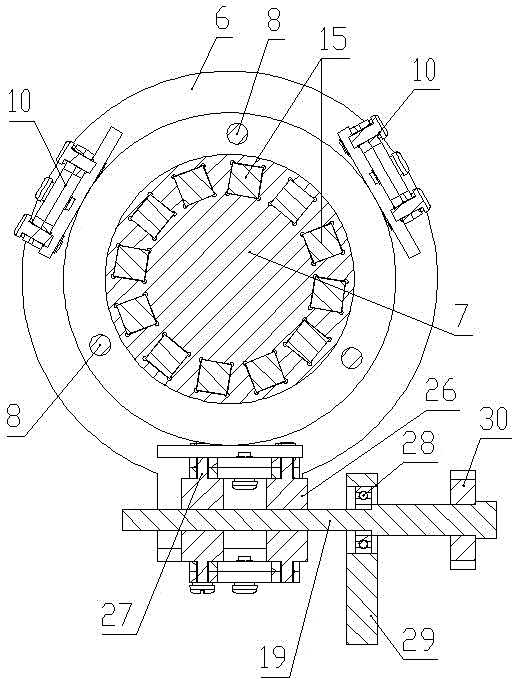

[0048] Such as Figure 1 to Figure 5 As shown, this embodiment provides an adjustable speed permanent magnet coupling, including a power input shaft 1, a drive shaft 2, a left sleeve 3, a right sleeve 4, a left control panel 5, a right control panel 6, an aluminum Alloy bearing disk 7, torque transmission shaft 8, driven shaft 9, parallelogram four-bar mechanism 10 and power output shaft 11;

[0049] The power input shaft 1 is connected to the driving shaft 2 through the first coupling structure, the left sleeve 3 is fixedly sleeved on the driving shaft 2, and the middle part of the left sleeve 3 is equipped with a first bearing 12, and the first bearing 12 is installed with a The left control panel 5 is described; the radial protrusion of the right end of the left sleeve 3 is provided with a left mounting plate 13, and a left copper ring 14 is installed on the right end surface of the left mounting plate 13;

[0050] The bearing disk 7 is fixedly connected to the left end of...

Embodiment 2

[0070] Such as Figure 6 As shown, the difference between this embodiment and Embodiment 1 is that the speed regulating mechanism is different.

[0071] The speed regulating mechanism includes a first threaded sleeve 35 arranged at the bottom of the left control panel 5, a second threaded sleeve 36 arranged at the bottom of the right control panel 6, and passing through the first and second threaded sleeves 35, 36 and The threaded speed regulating shaft 19 which is threadedly connected with the first and the second threaded sleeves 35 and 36 respectively.

[0072] The threaded speed regulating shaft 19 is bounded by the middle part, and the external threads on both sides of the middle part are in the opposite direction. The external thread on the other side of 19 is compatible with the internal thread of the second threaded sleeve 36; the external thread is an existing conventional technology, and the two sections of external thread on the thread speed regulating shaft 19 are...

Embodiment 3

[0079] Such as Figure 7 As shown, the difference between the present embodiment and the second embodiment lies in that the speed regulating mechanism is different.

[0080] The speed regulating mechanism is a gear pair speed regulating mechanism, including a first threaded sleeve 35 arranged at the bottom of the left control panel 5, a second threaded sleeve 36 arranged at the bottom of the right control panel 6, and a bevel gear speed regulating device;

[0081]The bevel gear speed regulating device includes a lower bevel gear 37, a left bevel gear 38 and a right bevel gear 39 installed in the gear box 42. The left bevel gear 38 is located on the left side of the lower bevel gear 37 and is meshed with the lower bevel gear 37. The bevel gear 39 is located on the right side of the lower bevel gear 37 and is meshed with the lower bevel gear 37;

[0082] The left bevel gear 38 is connected with the left speed regulating shaft 40, the right bevel gear 39 is connected with the ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com