Three-position switch for transferring current by quickly disconnecting bus

A three-position switch and bus transfer technology, applied in the field of high-voltage power transmission and distribution, can solve the problems of poor safety, easy divergence, weak airflow, etc., and achieve the effects of convenient processing, difficult divergence, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] Specific embodiments of the present invention are provided below in conjunction with the accompanying drawings.

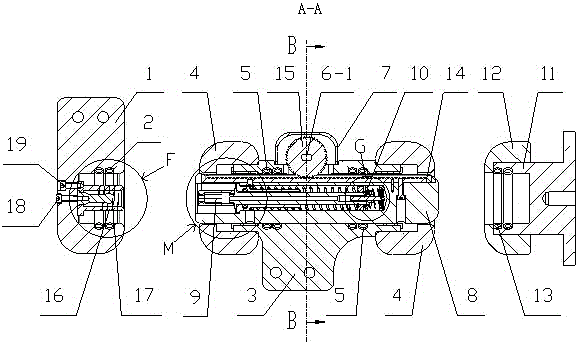

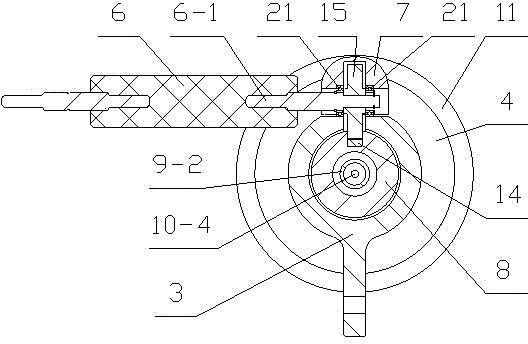

[0055] Such as Figure 1 to Figure 7 As shown, the present invention includes an isolated conductor 1, an intermediate conductor 3 and a grounding conductor 11, the isolated conductor 1, the intermediate conductor 3 and the grounding conductor 11 are on the same axis, and intermediate shielding rings 4 are respectively installed at both ends of the intermediate conductor 3, A ground shielding ring 12 is installed at the left end of the ground conductor 11, and a ground Basel spring 13 is installed in the inner cavity of the ground conductor 11, and an isolated Basel spring 2 and a spiral conductor 16 are installed in the inner cavity of the isolated conductor 1, such as Figure 8 with Figure 9 As shown, the spiral conductor 16 is a conductor with a transparent spiral groove 16-1 processed on the copper tube to form a spiral conduction mode, and a step ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com