Quick argon feeding method for air separation device

An air separation and rapid technology, applied in liquefaction, coagulation, lighting and heating equipment, etc., can solve the problems of repeated working conditions of argon system, long interval time, and reduced pressure of external pipe network, so as to shorten adjustment time and reduce venting loss. , the effect of improving utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

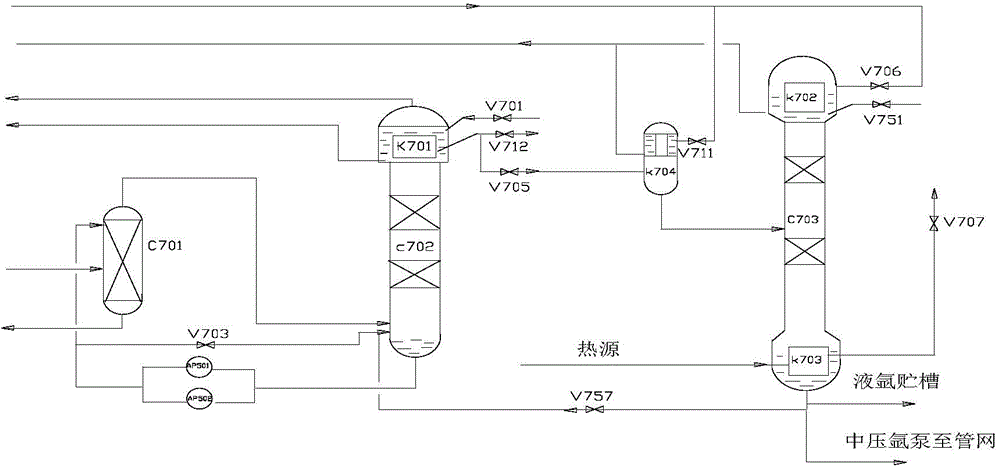

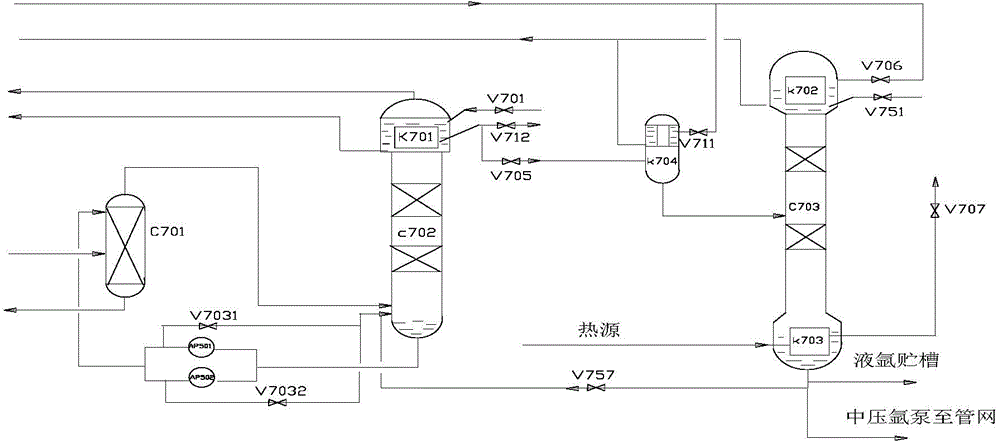

[0040] Attached below figure 2 And embodiment technical scheme of the present invention is described further:

[0041] Example 1

[0042] Take the KDON21000 / 22000 / 750 air separation unit of Laiwu Iron and Steel Group Co., Ltd. as an example.

[0043]A rapid argon injection technology for the air separation unit. When the air separation unit is started and the argon tower is put into the argon tower, when the argon fraction is about 6%, the throttle valve V701 of the crude argon condenser can be gradually opened to increase the load of the crude argon condenser K701; start The pre-cooled first circulation liquid argon pump AP501 or the second circulation liquid argon pump AP502, correspondingly, gradually close the first pump return valve V7031 or the second pump return valve V7032, and slowly pump the liquid at the bottom of the crude argon column II C702 Enter the crude argon column IC701, establish the rectification working condition of the crude argon column, during this...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com