A discontinuous air guide tube for an axial flow fan

A technology of axial flow fan and air guide tube, which is applied to components of pumping devices for elastic fluids, mechanical equipment, non-variable pumps, etc., and can solve the problem of reducing fan efficiency, increasing wind wheel resistance, and increasing fan Noise and other problems can be achieved to reduce the loss of air volume and air pressure, avoid eddy currents, and avoid internal leakage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

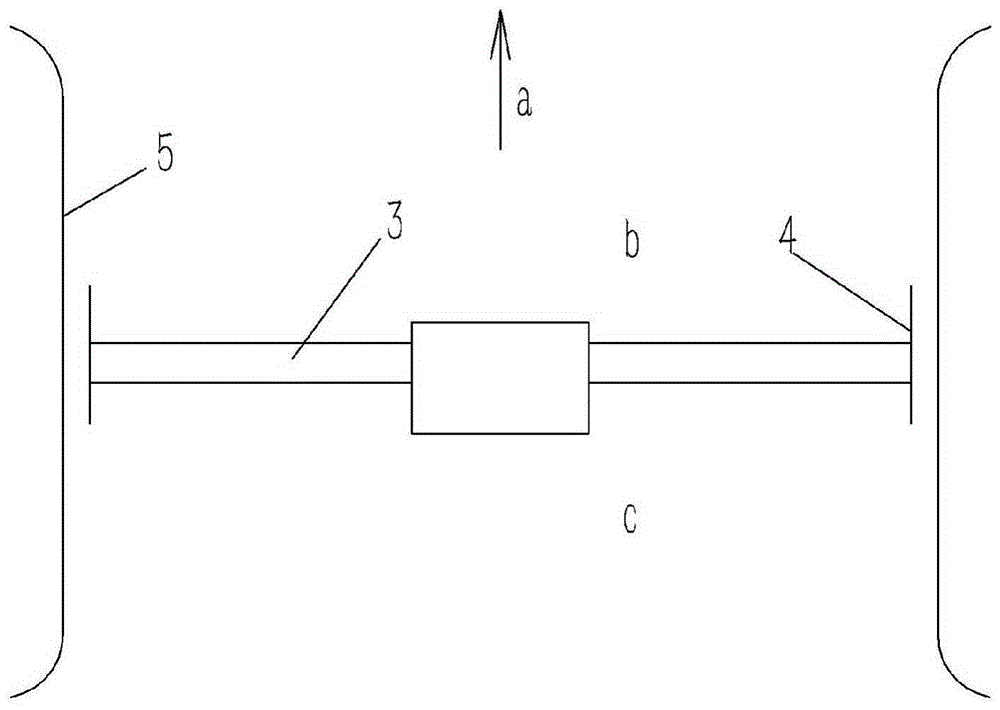

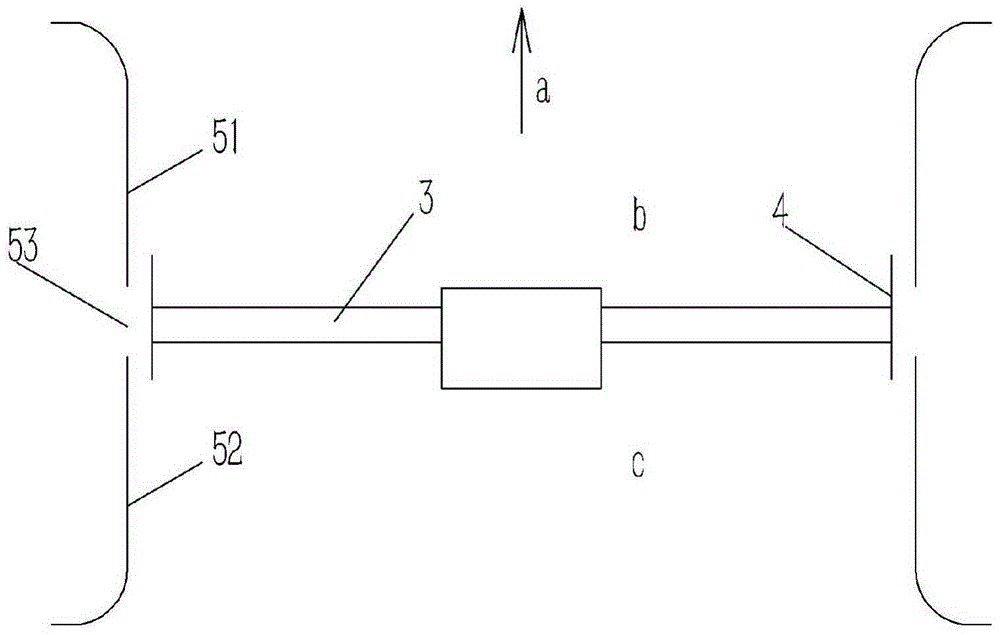

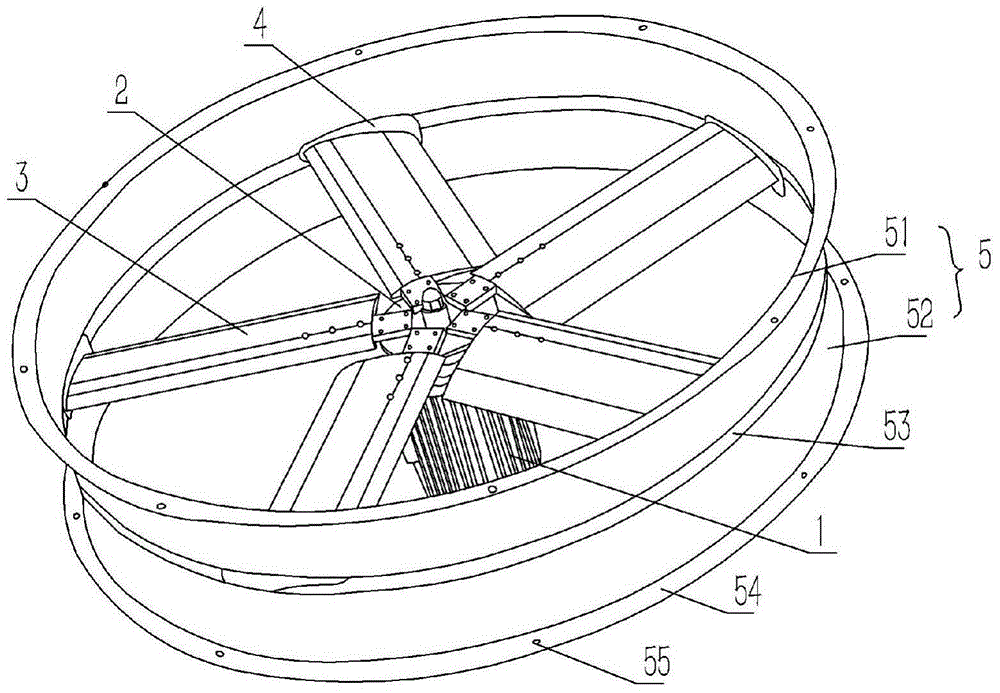

[0020] Example: see figure 2 , 3 As shown, a discontinuous air guide tube of an axial flow fan includes a motor 1 and an air guide tube 5, a rotating disc 2 is fixedly connected to the rotating shaft of the motor 1, and a plurality of fan blades 3 are connected to the rotating disc 2 by bolts. 3. Placed in the air guide tube 5, the upper and lower ends of the air guide tube 5 are formed with outwardly extending flanges 54, and the flanges 54 are formed with bolt holes 55, facing the air guide tube 5 at the outer end of the fan blade 3 An annular slot 53 is formed on the tube wall, and the slot 53 divides the air guiding tube 5 into two upper and lower cylinders of an air outlet tube 51 and an air inlet tube 52 .

[0021] The fan blades 3 are evenly distributed on the turntable 2 in a circular shape, and the outer ends of the fan blades 3 are fixedly connected with the fins 4 , and the slots 53 for dividing the air guide tube 5 are located on the horizontal outer side of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com