Booster type electronic control hydraulic bridge plug feeding tool

An electronically controlled hydraulic and bridge plug technology, applied in wellbore/well parts, earthwork drilling and production, etc., can solve the problems of short service life, long operation time, low work efficiency, etc., and achieve safe and reliable working process and simple maintenance , high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

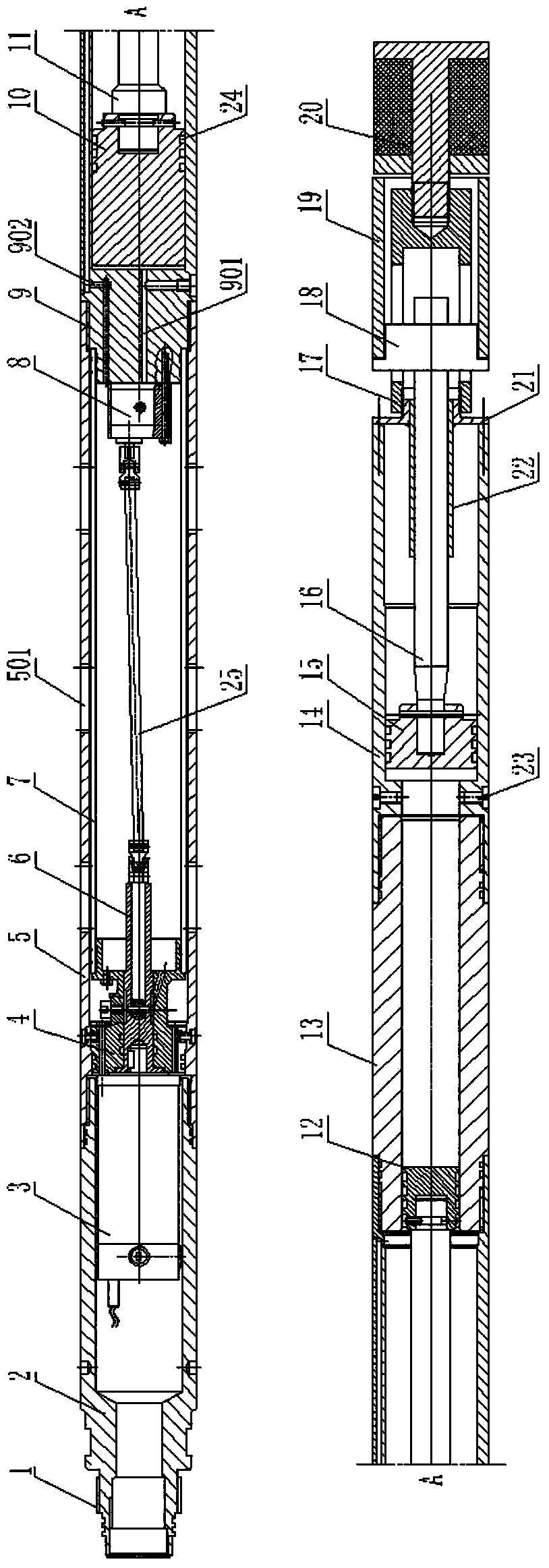

[0022] Such as figure 1 As shown, the pressurized electronically controlled hydraulic bridge plug insertion tool includes a motor cylinder 2, a balance cylinder 5, a hydraulic pressure boosting system and a working cylinder which are threaded sequentially from top to bottom. A connecting plug 1 integrated with the motor barrel 2 is provided at the upper end of the motor barrel 2, and a motor 3 is arranged in the motor barrel 2. As preferably, the motor 3 is a rare-earth DC motor, and the motor 3 wires are drawn from the upper end of the motor barrel 2. A motor base 4 is fixed on the inner upper part of the balance cylinder 5 by screws, and the motor 3 is fixed on the upper end of the motor base 4 by bolts. A transmission shaft 6 runs through the inner hole of the motor base 4 , and the upper end of the transmission shaft 6 is keyed to the output shaft of the motor 3 . A plurality of ventilation slots 501 are symmetrically provided on the cylinder wall of the balance cylinder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com