Organic compound fertilizer and manufacturing method thereof

A production method and compound fertilizer technology, applied in the field of agriculture, can solve problems such as unsuitable for production promotion, long preparation cycle, cumbersome steps, etc., achieve low production cost, improve the ability to resist diseases and insect pests, and achieve the effect of uniform composition

Inactive Publication Date: 2014-09-03

GUANGXI SOURCE OF THE FERTILIZER IND

View PDF5 Cites 23 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

But its disadvantages are: the steps in the preparation method are cumbersome, the preparation cycle is long, and it is not suitable for mass production and promotion.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0040]

Embodiment 2

[0042]

Embodiment 3

[0044]

[0045]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

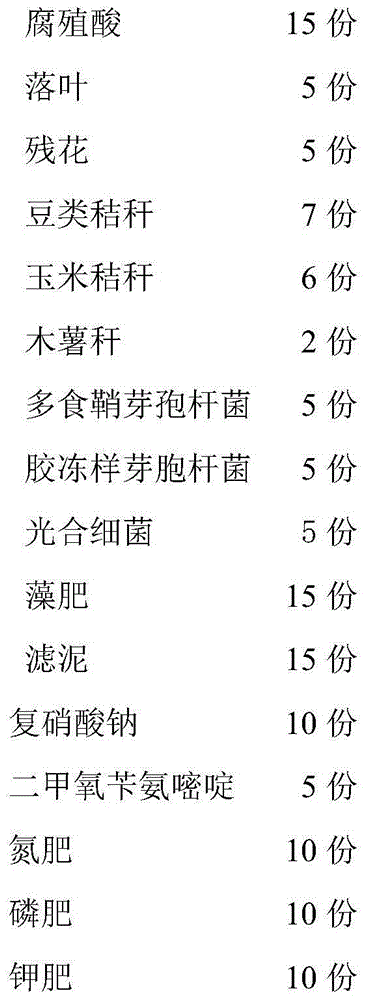

The invention discloses an organic compound fertilizer and a manufacturing method thereof. The organic compound fertilizer comprises the following components in parts by weight: 10-15 parts of humic acid, 20-25 parts of crop waste, 5-10 parts of biological microbial inoculant, 10-15 parts of alga fertilizer, 10-15 parts of lime sludge, 5-15 parts of synergist, 5-10 parts of nitrogen fertilizer, 5-10 parts of phosphate fertilizer and 5-10 parts of potassium fertilizer. The manufacturing method comprises the following steps: preparing raw material mixture powder; fermenting to obtain the organic compound fertilizer; and drying, granulating, screening, carrying out vacuum packaging with an aluminum foil, and the like. The biological microbial inoculant is utilized to ferment the agricultural waste, and the fermented agricultural waste is mixed with nutrient substances required by plants to prepare the organic compound fertilizer capable of enhancing the soil fertility and promoting growth of plants grown on the soil; and the organic compound fertilizer can sufficiently recycle the agricultural waste, thereby reducing the agricultural pollution and promoting the agricultural development.

Description

Technical field [0001] The invention belongs to the field of agricultural technology, and particularly relates to an organic compound fertilizer and a preparation method thereof. Background technique [0002] Fertilizer is an indispensable means of production for agriculture and forestry, especially in a country like China where arable land resources are limited and after years of cultivation, the fertility of the land has seriously declined. Long-term application of chemical fertilizers is likely to cause problems such as soil acidification, and the production and application of chemical fertilizers are likely to pollute the environment. Searching for environmentally friendly organic fertilizers is a subject faced by related researchers. Organic wastes such as sludge, livestock manure, pomace, soy sauce residue, medicine residue, dead branches and leaves, grass carbon, rice husk, etc. produced in daily production and life are rich in nutrients such as nitrogen, phosphorus, pota...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C05G1/00C05G3/00C05G3/02A01N63/04A01N63/00A01N25/30A01P3/00A01P7/04A01P21/00C05G3/60

Inventor 陈作军王修海陈明吴志勇

Owner GUANGXI SOURCE OF THE FERTILIZER IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com