Travelling crane capable of achieving multistation feed at same time period

A multi-station, material feeding technology, applied in the direction of conveyors, mechanical conveyors, transportation and packaging, etc., can solve problems such as inability to use, and achieve the effects of saving time, saving resources and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

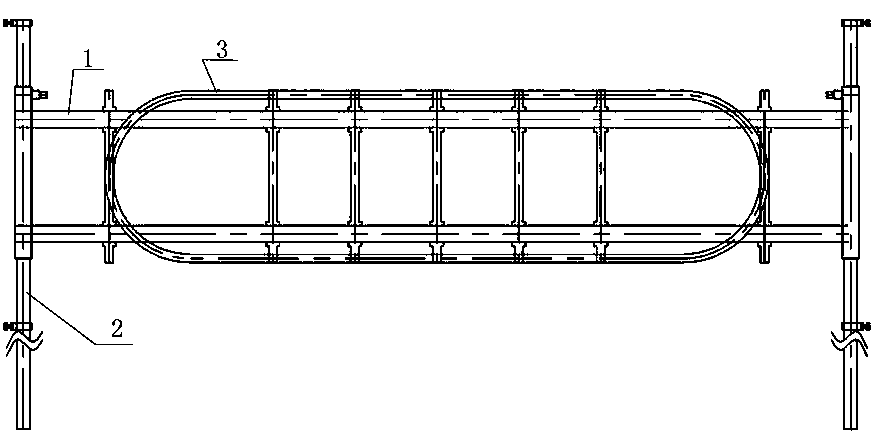

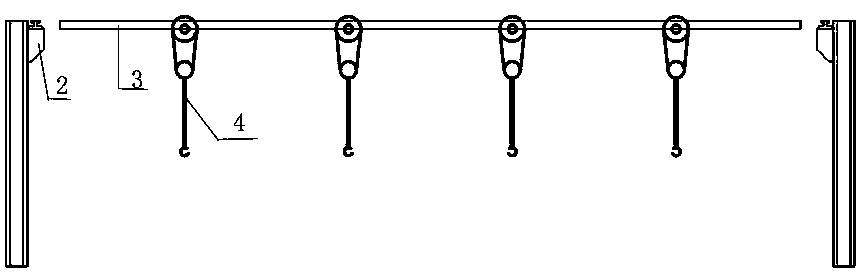

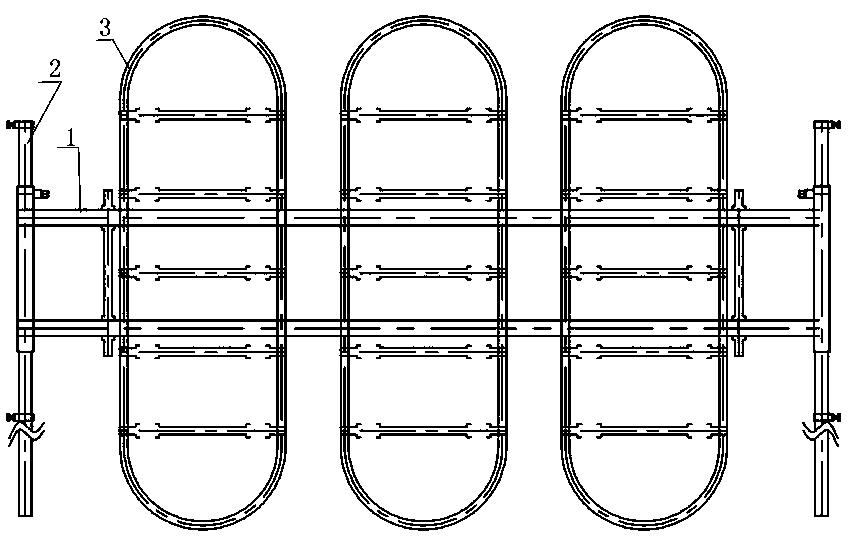

[0023] The present invention as figure 1 , 2 , 3, 4, 5, 6, and 7.

[0024] At the same time, the multi-station feeding crane includes the driving longitudinal beam 1, the two ends of the driving longitudinal beam 1 are erected on the guide rail 2, and a ring guide rail is arranged under the driving longitudinal beam 2, and a plurality of spreaders 4 are arranged on the ring guide rail .

[0025] There are one or more ring guide rails.

[0026] The annular guide rail is composed of a ring 5 shape or a waist shape 3 or a plurality of irregular arc segments 6 .

[0027] The circular guide rail in the shape of the circular ring 5 is connected in series by two circular rings.

[0028] There are one or more annular guide rails in the waist shape 3, which are arranged in the same direction or transversely with the running longitudinal beam 1 and are connected in series.

[0029] The structure of the present invention is based on the driving longitudinal beam 1 of the workshop, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com