Preparation method of laser controllable synthesis of monodisperse active metal nanoparticles

An active metal and nanoparticle technology, which is applied in the field of preparation of active metal nanoparticles, can solve the problems of inability to realize the size control of active metal nanoparticles, difficulty in synthesizing monodisperse active metal nanoparticles, etc., and achieves easy control, good dispersibility, Easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) Using a cadmium target with a purity of 99.999% and a thickness of 5mm as a raw material, sand the surface of the target to remove its oxide layer; place the metal target in distilled water for ultrasonic cleaning for 2 minutes, and then place it in cyclohexane Ultrasonic cleaning for 2 minutes; repeat three times and then air dry naturally to dry the surface of the target.

[0027] (2) if figure 1 As shown in (a), the cadmium target is placed in 20 mL of oleic acid ethanol solution, the volume percentage of oleic acid is 0.1%, the distance between the liquid surface and the upper surface of the cadmium target is 5 mm, and a nanosecond pulse laser with a wavelength of 1064 nm is used to focus on On the upper surface of the target, the laser energy density is about 120mJ / cm 2 , repetition frequency 5Hz; the whole process is protected by an argon flow with a flow rate of 60sccm to prevent the oxidation of cadmium and to remove oxygen; and it needs to be supplemented ...

Embodiment 2

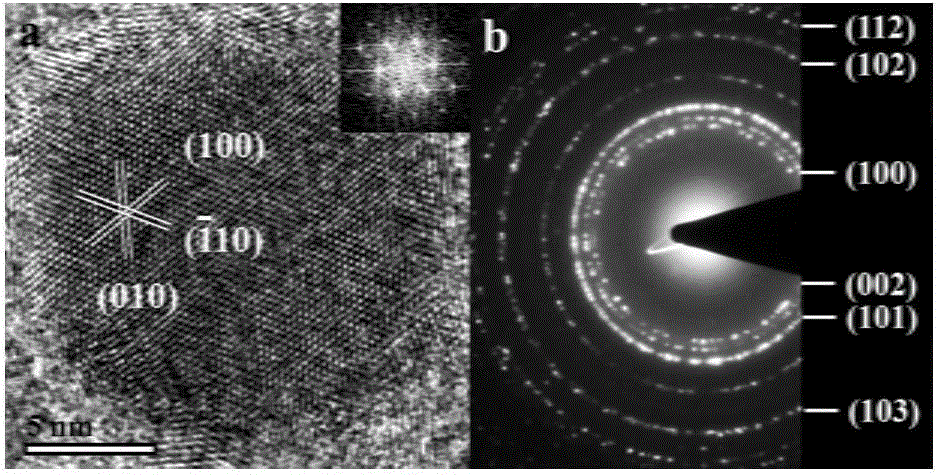

[0034] With respect to embodiment 1, in the step (3), the laser energy parameter is changed into 250mJ, and all the other conditions are constant, and the corresponding characterization of the monodisperse cadmium nanoparticles obtained is as follows Figure 4 (a) ~ (c) shown. from Figure 4 (a) It can be seen that the prepared particles have good dispersion and uniform size, Figure 4 (b) reflects the good crystallinity of a single particle, Figure 4 (c) According to particle size statistics, the size of the product obtained by parallel pulsed laser irradiation at 250mJ energy is 13.6±1.0nm, and the size distribution is 7.3%, which also meets the requirement of monodisperse size distribution of less than 10%.

Embodiment 3

[0036] With respect to embodiment 1, in step (3), laser energy parameter is changed into 300mJ, and all the other conditions are constant, and the corresponding characterization of the monodisperse cadmium nanoparticle that obtains is as follows Figure 5 (a)~(c), from Figure 5 (a) It can be seen that the prepared particles have good dispersion and uniform size, Figure 5 (b) reflects the good crystallinity of a single particle, Figure 5 (c) According to particle size statistics, the size of the product obtained by parallel pulsed laser irradiation at 300mJ energy is 10.1±1.0nm, and the size distribution is 9.9%, which also meets the requirement of monodisperse size distribution of less than 10%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com