Self-selecting crusher that can automatically sort hard objects

An automatic sorting and crusher technology, applied in the direction of grain processing, etc., can solve the problems of low working efficiency, failure to reach the crushing particle size, shortened service life, etc., to improve crushing quality and efficiency, ensure the output particle size, and work efficiency high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

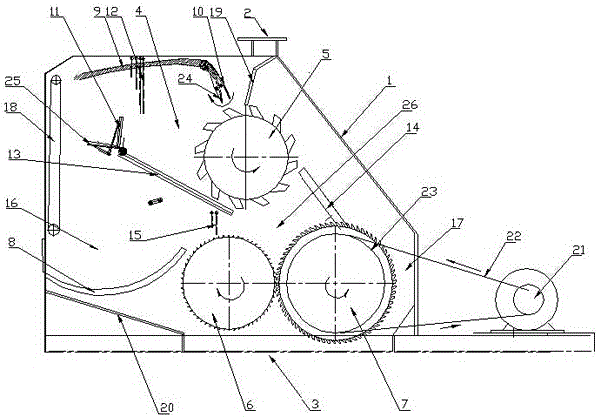

[0023] A self-selection crusher capable of automatically sorting hard objects, comprising a shell 1, a feed port 2 and a discharge port 3, the inner cavity of the shell 1 is divided into a primary crushing chamber 4 and a secondary crushing chamber Chamber 26, wherein, the primary crushing chamber 4 includes the first working pair 5 and the blocking mechanism located below the feed inlet 2, and the secondary crushing chamber 26 includes the second working pair located below the primary crushing chamber 4 6 and the third working pair 7, and a screen 8 is set between the second working pair 6 and the housing 1, and the diameter of the screen 8 is greater than or equal to the particle size requirement of the medium.

[0024] As a preference, the blocking mechanism is arranged on the flying path of the medium from the first working pair 5, including the elastic movable tongue 10 of the feed inlet at the end of the upper crushing plate 9, the elastic material selection tongue 11, an...

Embodiment 2

[0026] On the basis of the above structure, a deflector 13 can be installed obliquely under the elastic material selection tongue 11 to guide the primary sorted crushed medium and a small amount of hard objects that have not been sorted out to the secondary selector. Broken chamber 26 for re-sorting and crushing.

[0027] In the secondary breaking chamber 26, above the third working pair 7, a counter-attack baffle 14 is set on the medium flying strike route, and the counter-attack baffle 14 is preferably arranged as perpendicular as possible to the medium flying strike direction, so that It can change the flying direction of the crushing medium and the mixture of hard objects flying in the secondary crushing chamber 26, so that the crushing medium is further broken, and reversely moves to between the second working pair 6 and the third working pair 7 for hard extrusion Broken, while making the hard objects move to the hard object holding area 16, and realize sorting again.

Embodiment 3

[0029] On the basic structure of the first and second embodiments, a partition plate 15 can also be set above the second working pair 6 on the medium flying path to separate the secondary breaking room 26 into a hard object storage area 16 and a secondary crushing area 17; a sound-absorbing and shock-absorbing barrier 18 is set above the hard object storage area 16; a feed baffle 19 is set between the feed port 2 and the first working pair 5 for adjusting the feed Feed angle for port 2.

[0030] There is an outlet guide plate 20 arranged obliquely below the screen 8, so that the medium that flies into the hard object holding area 16 and whose particle size is smaller than or equal to the diameter of the screen 8 meshes, under its own gravity, from After falling from the screen 8, it moves to the discharge port 3 along the material guide plate 20 of the discharge port.

[0031] The power mechanism can be two groups, including structures such as motor 21, power belt, transmissi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com