Preparation method of magnesium oxide-mesoporous carbon composite material

A composite material and mesoporous carbon technology, applied in chemical instruments and methods, and other chemical processes, can solve the problems of poor recycling performance, high energy consumption, and low adsorption capacity, and achieve excellent performance, high specific surface area, and reduced Effect of regenerative energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

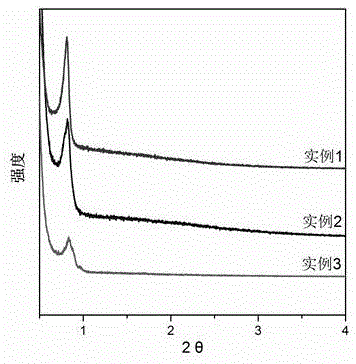

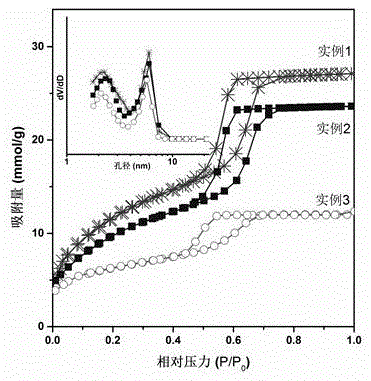

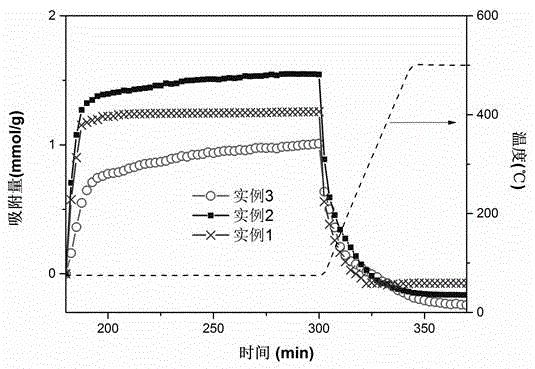

[0028] In this example, see figure 1 and figure 2 , a preparation method of magnesium oxide-mesoporous carbon composite material MgO / C-1-500, comprising the steps of:

[0029] a. According to the formula mass ratio: F127 / resol / TEOS / EtOH / HCl / H2O=1.6:1.0:2.08:12:7.3×10 -3 : 1.0, prepare mesoporous carbon material, adopt nitric acid as oxidant, nitric acid is dissolved in water, make the nitric acid modifier solution that concentration is 5mol / l, then at 40 ℃, 1.0g mesoporous carbon material is immersed in the nitric acid of 20g In the modifier solution, stir for 4 hours to oxidize the surface of the mesoporous carbon material; then repeatedly wash and filter the oxidized mesoporous carbon material until the pH value of the filtrate is neutral, and the mesoporous carbon material is completed. preprocessing;

[0030] b. The mesoporous carbon material that has been pretreated in the above step a is subjected to vacuum desorption in a vacuum oven for 6 hours at a drying tempera...

Embodiment 2

[0034] This embodiment is basically the same as Embodiment 1, especially in that:

[0035] In this example, see figure 1 and figure 2 , a preparation method of magnesium oxide-mesoporous carbon composite material MgO / C-2-500, comprising the steps of:

[0036] a. This step is the same as in Embodiment 1;

[0037] b. This step is identical with embodiment one;

[0038]c. The volume ratio of the mixed components of water and ethanol is mixed in the ratio of 1:1, the mixed solution of water-ethanol system, then 1.45gMg(NO 3 ) 2 ·6H 2 O is fully dissolved in 10g of water-ethanol mixed solution to prepare a magnesium nitrate solution, and then the magnesium nitrate solution is added dropwise on the dry mesoporous carbon material, and then left to stand at room temperature for 24 hours, so that the magnesium nitrate solution is fully impregnated into the mesoporous carbon material. The surface of the porous carbon material is then placed in an oven at 80° C. for drying for 6...

Embodiment 3

[0041] This embodiment is basically the same as the previous embodiment, and the special features are:

[0042] In this example, see figure 1 and figure 2 , a preparation method of magnesium oxide-mesoporous carbon composite material MgO / C-3-500, comprising the steps of:

[0043] a. This step is the same as in Embodiment 1;

[0044] b. This step is identical with embodiment one;

[0045] c. The volume ratio of the mixed components of water and ethanol is mixed in the ratio of 1:1, the mixed solution of water-ethanol system, then 2.15gMg(NO 3 ) 2 ·6H 2 O is fully dissolved in 10g of water-ethanol mixed solution to prepare a magnesium nitrate solution, and then the magnesium nitrate solution is added dropwise on the dry mesoporous carbon material, and then left to stand at room temperature for 24 hours, so that the magnesium nitrate solution is fully impregnated into the mesoporous carbon material. The surface of the porous carbon material is then placed in an oven at 8...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com