Efficient spraying machine suitable for cotton fields

A sprayer, a high-efficiency technology, applied in the application, device for catching or killing insects, animal husbandry, etc., can solve the problem of blowing branches and leaves, poor turning effect, weak penetration, poor control and defoliation effects, etc. problems, to achieve the effect of improving the effect of pesticide application, ensuring the effect of pesticide application and ensuring the benefit of cotton

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

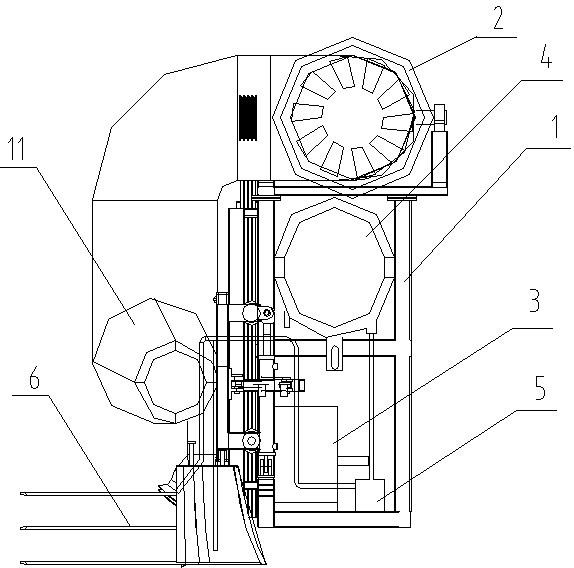

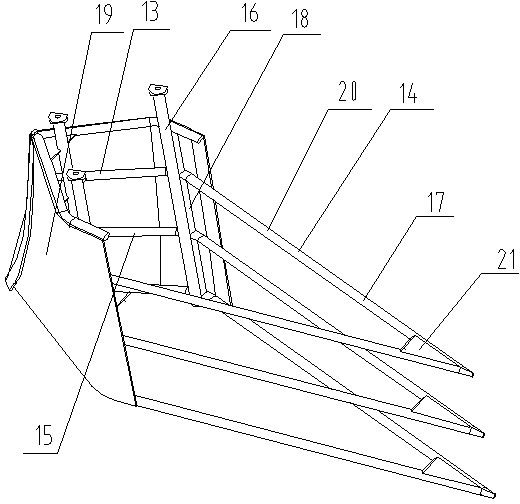

[0044] Such as figure 1 , 2 , shown in 14, a kind of high-efficiency sprayer that is applicable to cotton field, comprises support 1, fan 2, fan power system 3, medicine box 4, drug pump 5, fan 2, medicine box 4, fan power system 3 are respectively fixed on the bracket 1, the outlet of the medicine box 4 is connected to the inlet of the medicine pump 5 through a pipeline, and the fan power system 3 is connected to the fan 2 through a pulley rotation mechanism; Distributor 6, straight spray cylinder 7, inclined spray cylinder 8, each distributor 6 is respectively fixed on the nozzle mounting bracket 9, each straight spray cylinder 7 is fixedly arranged in each distributor 6, and the upper end of the straight spray cylinder 7 is fixed on the nozzle On the mounting bracket 9, the air outlet of the straight spray tube 7 faces the plant; the oblique spray tube 8 is fixed on the nozzle mounting bracket 9, and the oblique air cylinder 8 is arranged above the straight spray cylinder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com