Blending effect computing method applicable to blending operation of iron ore powder

A technology of operation production and calculation method, applied in calculation, special data processing application, instrument, etc., can solve the problems of negative effect, not in line with the actual production of mixing operation, zero effect, etc., and achieve the effect of accurate data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

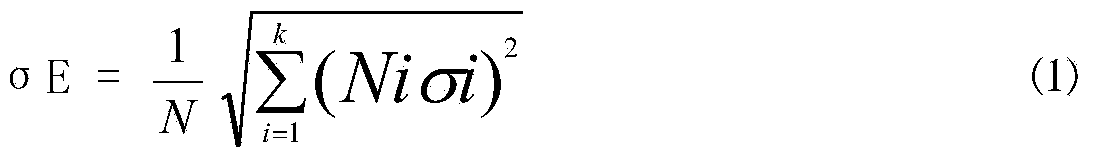

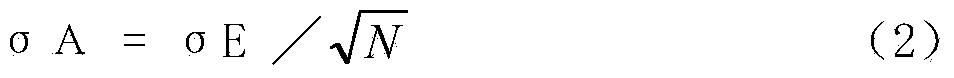

[0087] A method for calculating the mixing effect suitable for iron ore powder mixing operations, characterized in that: the following steps are carried out:

[0088] (1) Carry out mathematical simulation to the iron ore powder mixing operation process to obtain the content P(A) of iron ore in the mixing material:

[0089] Assuming that the raw materials participating in the mixing are only composed of iron ore and gangue, therefore, the mixing production process of the mixing operation process should be regarded as n times of independent repeated Bernoulli experiments, and A represents "iron ore appears". "In this event, 1-A represents the event of "appearance of gangue" or "absence of A". In this way, comparing the number of occurrences of A with the total number of times is the probability of occurrence of A, that is, the percentage content P(A)(%) of iron ore in the mixed material. Therefore, the total probability formula for the occurrence of iron ore in the mixed materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com