Capability verification sample for detection of textile color fastness to rubbing and preparation method thereof

A proficiency verification and friction-resistant technology, which is applied in the preparation of test samples, measurement devices, and mechanical devices, etc., to achieve the effect of simple preparation method and high success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Embodiment 1, select dyestuff to be direct blue 2R for use

[0042] (1) Select the base fabric: select a pure cotton woven plain bleached gray fabric with a smooth surface and no defects. The parameters of the gray fabric are: warp density 226 threads / 10cm, weft density 144 threads / 10cm, warp and weft yarn count 40Ne, The weight per square meter is 160g / ㎡, and the width is 150cm.

[0043] (2) Select the dyeing method: use the overflow dyeing method, and use the SME30 overflow dyeing machine.

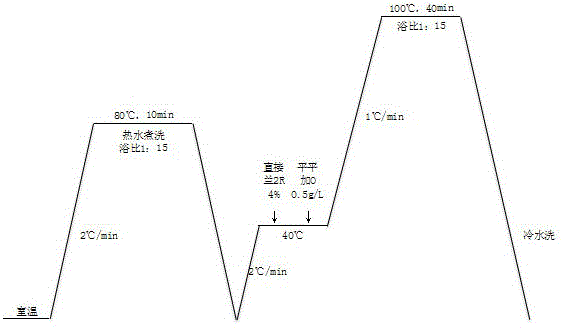

[0044] (3) Choose dye and formula: Direct Blue 2R. Its formula is: Direct Blue 2R 4% (o.w.f), Pingping plus O (leveling agent): 0.5g / L, the dyeing process curve is shown in figure 1 .

[0045] (4) Dyeing: The bath ratio is 1:15, and the dyeing process is: base fabric preparation → pretreatment → dyeing → washing → dehydration → drying, tentering and shaping → cloth inspection and rolling.

[0046] 1) Base fabric preparation: cut the base fabric according to the length required...

Embodiment 2

[0059] Embodiment 2, selects the dyestuff to be straight mixed blue D-RGL+coating for use

[0060] (1) Select the base fabric: select a pure cotton woven twill bleached gray fabric with a smooth surface and no defects. The parameters of the gray fabric are: warp density 260 threads / 10cm, weft density 140 threads / 10cm, warp and weft yarn count 40Ne, The weight per square meter is 158g / ㎡, and the width is 150cm.

[0061] (2) Select the dyeing method: overflow dyeing method, using SME30 overflow dyeing machine;

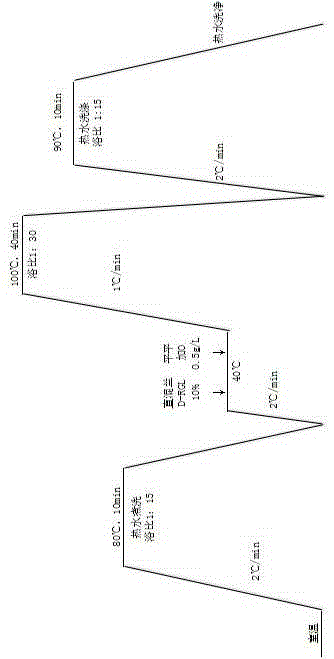

[0062] (3) Select dye and formula: direct mixed blue D-RGL + paint. Its formula is: straight mixed blue D-RGL 10% (o.w.f) + 0.25% paint (o.w.f), Pingping plus O (leveling agent): 0.5g / L, the dyeing process curve is shown in figure 2 ;

[0063] (4) Dyeing: The bath ratio is 1:30, and the dyeing process is as follows: base fabric preparation → pretreatment → dyeing → washing → dehydration → scraping paint → drying, tentering, shaping → cloth inspection, rolling;

[00...

Embodiment 3

[0078] Embodiment 3, selecting dyestuff for use is reactive dark blue B-2GLN 2%

[0079] (1) Select the base fabric: select a pure cotton woven plain bleached gray fabric with a smooth surface and no defects. The parameters of the gray fabric are: warp density 226 threads / 10cm, weft density 144 threads / 10cm, warp and weft yarn count 40Ne, The weight per square meter is 160g / ㎡, and the width is 150cm.

[0080] (2) Select the dyeing method: overflow dyeing method, using SME30 overflow dyeing machine.

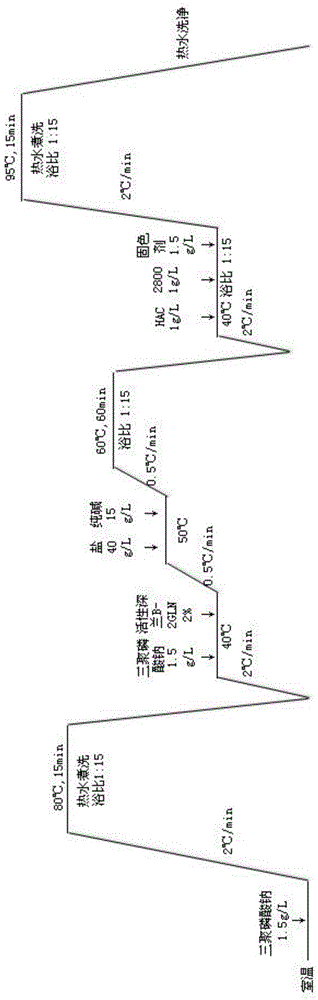

[0081] (3) Select dye and formula: active deep blue B-2GLN 2%. Its formula is: active dark blue B-2GLN 2% (o.w.f), sodium tripolyphosphate 1.5g / L, salt 40g / L, soda ash 15g / L, HAC 1g / L, surfactant 2800 1g / L, color fixation 1.5g / L, the dyeing process curve is shown in image 3 .

[0082] (4) Dyeing: The bath ratio is 1:15, and the dyeing process is: base fabric preparation → pretreatment → dyeing → washing → dehydration → drying, tentering and shaping → cloth inspection and roll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com