Discharge device for rotary hearth furnace

A rotary hearth furnace and discharge technology, which is applied to furnaces, furnace types, furnace components, etc., can solve the problems of low discharge efficiency, dirty discharge, and low service life, so as to increase the discharge area and improve discharge efficiency. Material effect, the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

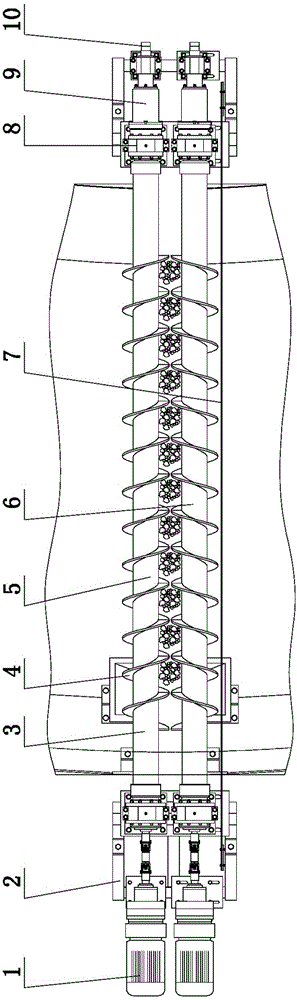

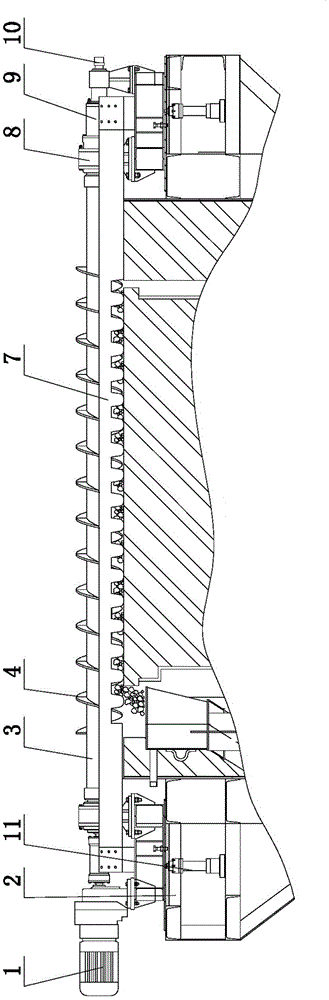

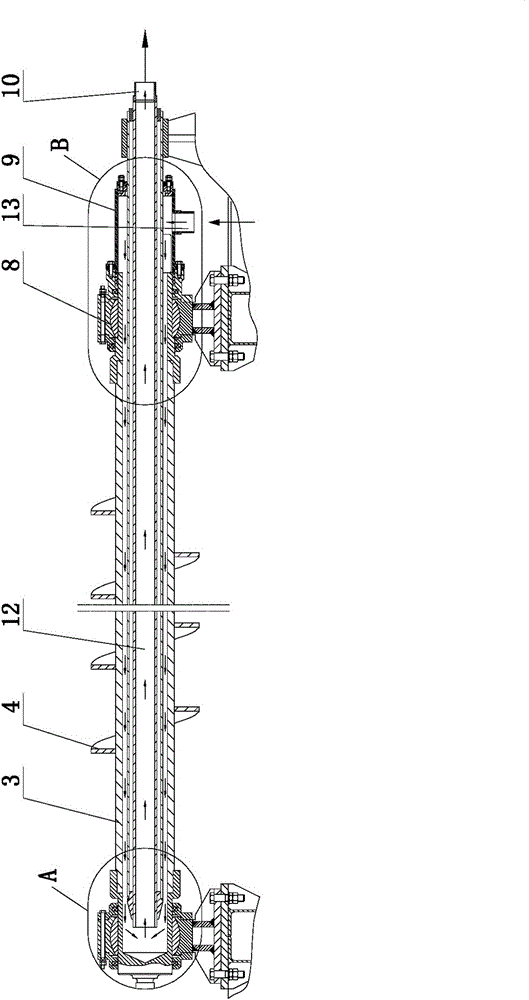

[0020] The present invention includes a first water-cooled screw 5 , and a second water-cooled screw 6 is arranged relative to the first water-cooled screw 5 .

[0021] Both ends of the first water-cooled screw 5 and the second water-cooled screw 6 are arranged on the lifting platform 2 connected with the hydraulic cylinder 11 .

[0022] A scraper 7 is arranged on the side of the first water-cooled screw 5 or the second water-cooled screw 6 . The scraper 7 can gather the scattered materials to the first water-cooled screw 5 or the second water-cooled screw 6, so that the first water-cooled screw 5 or the second water-cooled screw 6 can smoothly discharge the materials, and at the same time, the scraper 7 plays the role of clearing the material to avoid Hearth stick.

[0023] The scraper 7 is set as an arc-shaped tooth structure, through the arc-shaped teeth, materials of appropriate size can pass through to avoid jamming

[0024] The scraper 7 is also arranged on the lifting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com