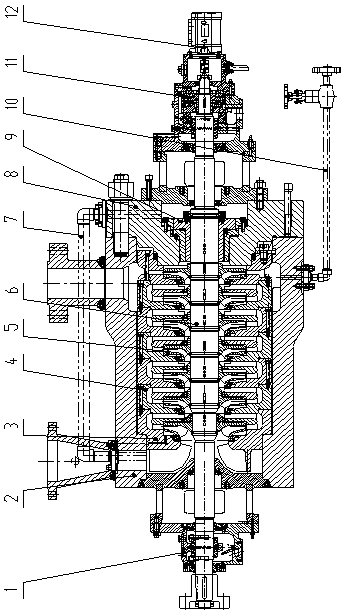

Double-cylinder sectional type horizontal multilevel centrifugal pump

A centrifugal pump and body segment technology, applied in the field of centrifugal pumps, can solve the problems of lack of stability and energy saving, and achieve the effects of compact structure, reliable operation and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing, the present invention is described in further detail:

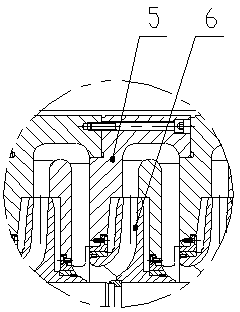

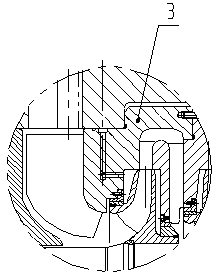

[0014] Such as figure 1 Shown, the present invention double barrel segmental horizontal multistage centrifugal pump is composed of driving end bearing part 1, cylinder body 2, suction box body 3, guide vane middle section 4, impeller 5, pump shaft 6, balance pipe part 7, pump Cover 8, balance mechanism 9, drain pipe 10, non-drive end bearing part 11 and other components, wherein the cylinder 2-1 in the sealed box located at the end of the drive-end bearing part is welded to the end plate 2-2 of the sealed box, The end plate 2-2 of the sealed box is welded with the cylinder (such as figure 2 shown); the guide vane and the middle section of the pump adopt an integrated structure, and the positive guide vane and the suction box are both open structures (such as image 3 shown). A shaft head oil pump 12 is connected to the end of the non-drive end bearing part (such a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com