Energy saving and efficiency improving method for plunger pump

A plunger pump, connected to the technology, applied in the pump, pump control, liquid variable capacity machinery and other directions, can solve the problems of low energy efficiency and mechanical efficiency, comprehensive work efficiency reduction, large mechanical loss, etc., to achieve shortened production cycle, The effect of reducing the difficulty of product maintenance and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

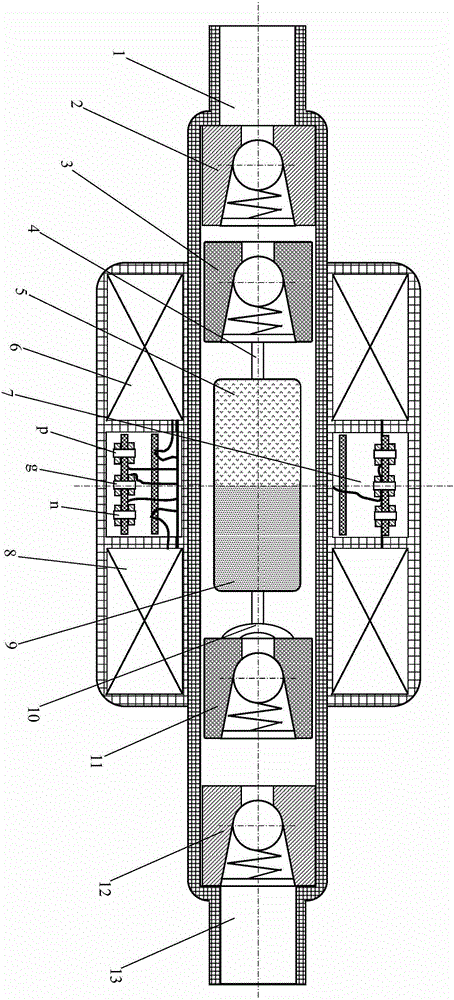

[0018] exist figure 1 In the illustrated embodiment of the invention—a linear drive plunger pump sectional view:

[0019] From left to right, the pump body of the linear drive plunger pump is divided into suction end, suction section, middle section, discharge section and discharge end. In the pump body, the suction section, the middle section, and the discharge section space between the suction valve 2 and the discharge valve 12 form a cylindrical piston cylinder; the suction end valve 3, the permanent magnet N pole 5, the permanent magnet S pole 9 and the discharge end valve 11 pass through The connecting structure of the connecting rod 4 and the connecting frame 10 constitutes a cylindrical piston. The piston is driven by the drive circuit through the N pole electromagnetic coil 6 and the S pole electromagnetic coil 8 .

[0020] Suction port 1, as the gas and liquid suction port and the installation end matched with the suction pipe, is located at the suction end of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com