Rapier loom special for wide fabric

A technology of rapier looms and wide-angle cloth, which is applied in looms, textiles, textiles, and papermaking. It can solve the problems of high cost, large waste, and low production efficiency, and achieve the effect of increasing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Specific embodiments of the present invention will be described below in conjunction with the accompanying drawings.

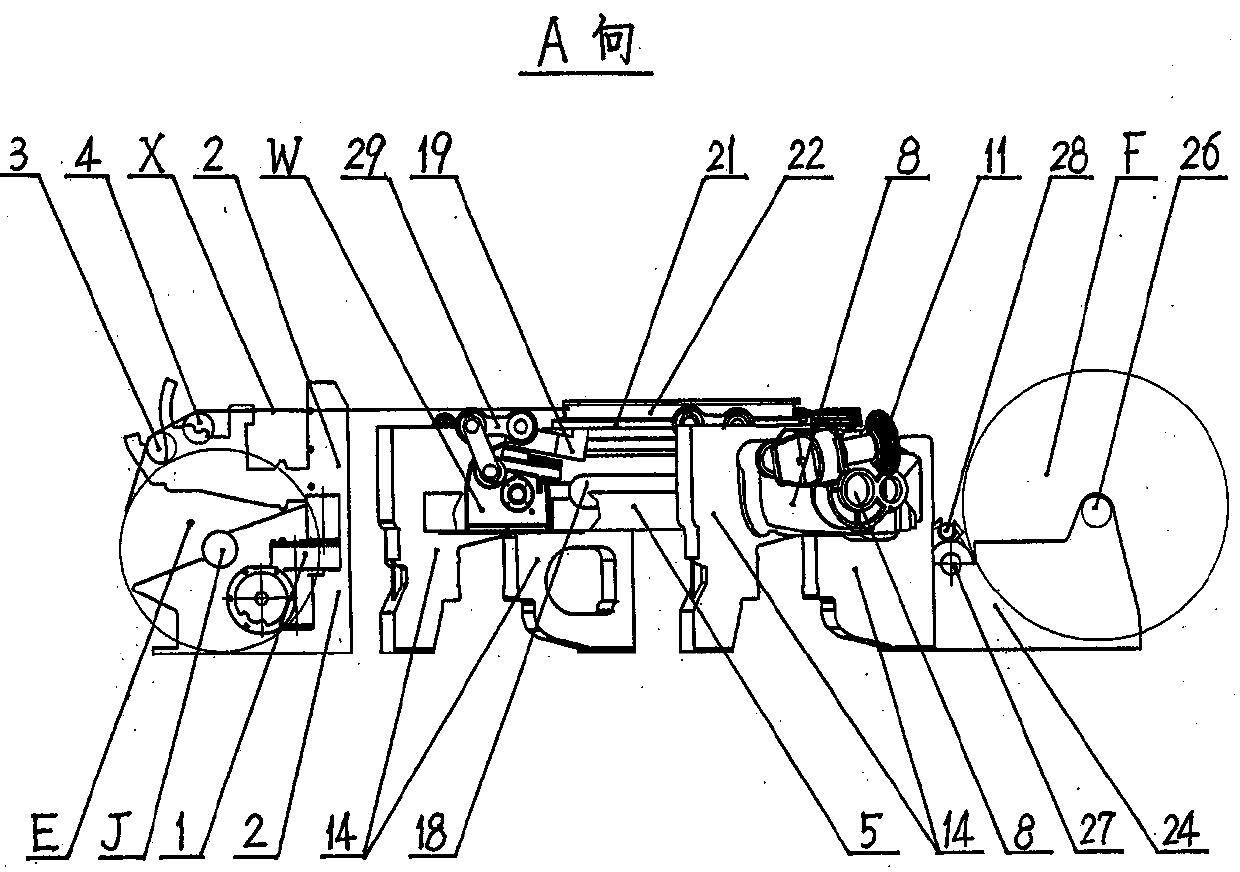

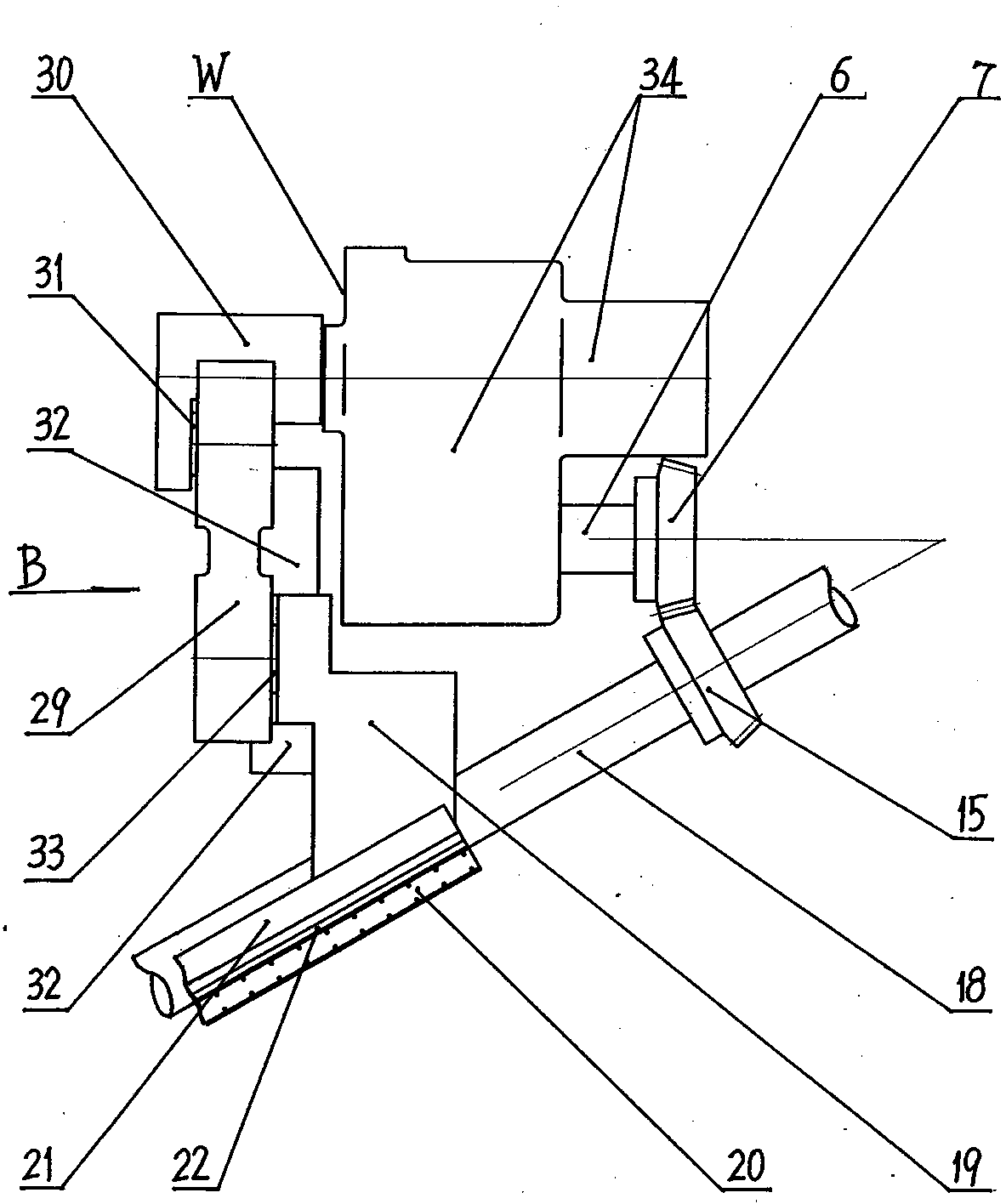

[0014] refer to figure 1 , figure 2 , the main frame 14 and the let-off frame 2 are placed at an oblique angle α, the inside of the two ends of the main frame 14 is provided with a beating mechanism W, and the shaft end of the conjugate cam mandrel 6 protrudes from the outside of the beating box 34, and the beating-up mechanism is fixed. The bevel gear 7 is engaged with the main shaft bevel gear 15 of the main drive shaft 18 of the main frame 14, and the main shaft 18 drives the conjugate cam mandrel 6 to rotate. The let-off frame 2 and the coiling frame 25 are placed in the same direction, the main frame 14 is installed between the let-off frame 2 and the coiling frame 25, and the main frame 14 is connected with the let-off frame 2 and the coiling frame 25. Diagonal setting. One end of the main frame 14 is provided with a main motor 13, the motor s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com