Paddle Type Automatic Cotton Boiler

An automatic, paddle technology, applied in animal raw materials, textiles and papermaking, fiber processing, etc., can solve the problems of low safety factor, low work efficiency, uneven mixing time and uniformity, etc., to achieve a high degree of automation, structural Simple and effective, high-efficiency cooking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The structure of the present invention will be described below in conjunction with the accompanying drawings and embodiments.

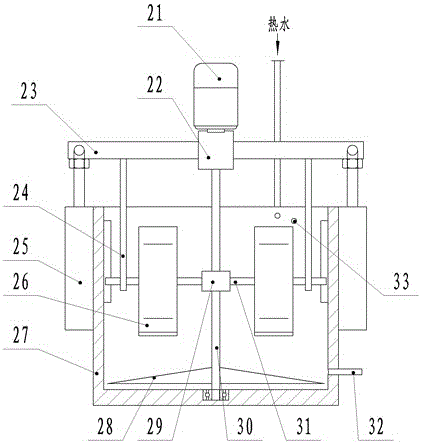

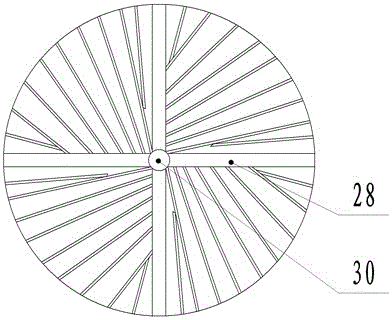

[0021] The hot water pipe of the boiler is connected to the cotton machine pot body 27, and the outer wall of the cotton machine pot body 27 is respectively equipped with a pneumatic cylinder or a hydraulic cylinder 25 along the center line, and a horizontal cylinder is installed on the lifting column of the pneumatic cylinder or hydraulic cylinder 25. The fixed support 23 spanning the pot body of the cotton cooking machine, the two sides of the fixed support 23 are equipped with rotating shaft supports 24, the middle of the fixed support 23 is arranged with a reducer 22 driven by a motor 21, and a vertical rotating shaft 30 is connected below the reducer 22. Rotating disc 28 is installed on rotating shaft 30 bottoms, and transmission box 29 is arranged in the middle of vertical rotating shaft 30, and a horizontal rotating shaft 31 fixed by rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com