Overlap-connecting structure of escalator truss

An escalator and truss technology, applied in escalators, transportation and packaging, etc., can solve the problems of space waste, cost increase, installation difficulty, etc., and achieve the effect of reducing cost, reducing deformation, and easy connection and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

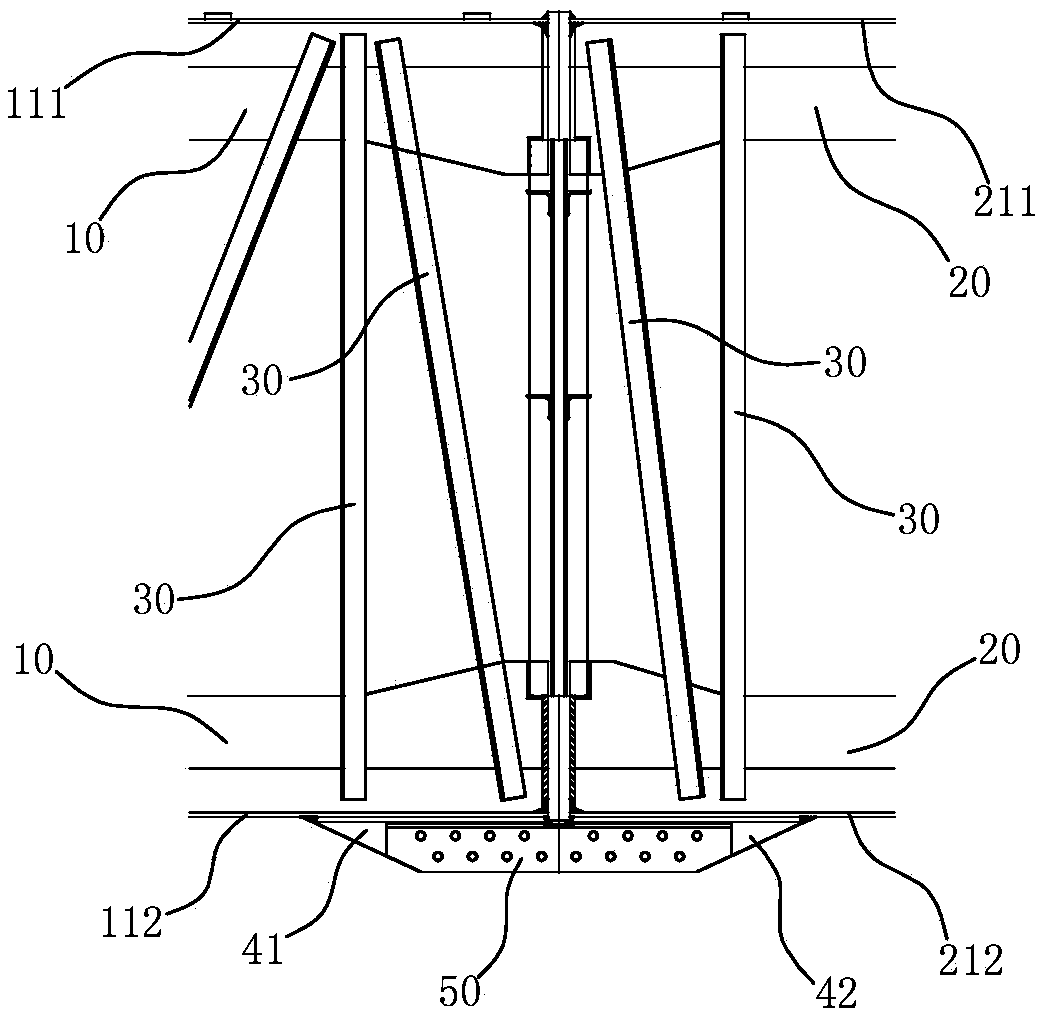

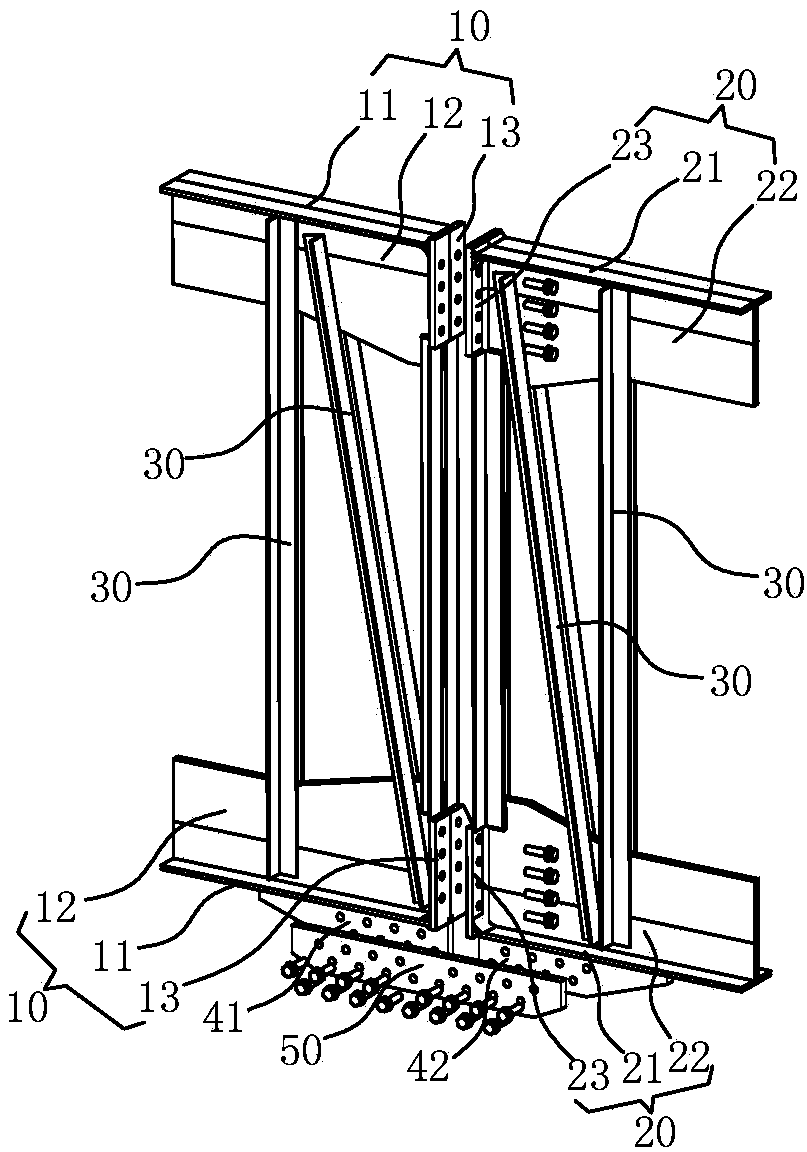

[0026] Such as Figure 1 to Figure 2 As shown, a connection structure of an escalator truss includes a first split truss and a second split truss, the first split truss includes two first main chords 10, and the two first main chords 10 are parallel to each other Or substantially parallel, and the two first main chords 10 are connected by a connecting beam 30, the second split truss includes two second main chords 20, and the two second main chords 20 are parallel or substantially parallel to each other, And the two second main chords 20 are also connected by a connecting beam 30 . The first main chord 10 includes a first main body 12, a first connecting end plate 13 and a first side 11, the first connecting end plate 13 and the first side 11 are both fixedly arranged on the first main body 12, the second The two main chords 20 include a second main body 22, a second connecting end plate 23 and a second side 21, the second connecting end plate 23 and the second side 21 are fi...

Embodiment 2

[0029] Such as image 3 As shown, the difference between this embodiment and Embodiment 1 is that the first fixed reinforcing plate 41 is only fixedly connected to the first upper side, and the first fixed reinforcing plate 41 is located outside the first upper side, which is image 3 The upper side of the first upper side, and the second fixed reinforcing plate 42 is only fixedly connected to the outer side of the second upper side, that is image 3 The upper side of the second upper side of the middle. Other structures of this embodiment are the same as those in Embodiment 1, and will not be repeated here.

Embodiment 3

[0031] Such as Figure 4 As shown, the difference between the present embodiment and the first embodiment is that the first fixed reinforcing plate 41 is fixedly connected on the first upper side and the first lower side, and the second upper side and the second The second fixed reinforcing plate 42 is fixedly connected on the lower side, and the first fixed reinforcing plate 41 on the first upper side is located on the outside of the first upper side, i.e. Figure 4 On the upper side of the first upper side, the first fixed reinforcing plate 41 on the first lower side is located on the outer side of the first lower side, that is, Figure 4 The lower side of the first lower side, and the second fixed reinforcement plate 42 on the second upper side is located on the outer side of the second upper side, that is Figure 4 On the upper side of the second upper side, the second fixed reinforcing plate 42 on the second lower side is located outside the second lower side, that is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com