Medal template manufacturing process

A technology for making craftsmanship and medals, applied in manufacturing tools, wood processing utensils, wood stamping and other directions, can solve the problems of operator's health impact, high scrap rate of sheet materials, high production cost, and reduce health impact and scrap rate. , the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] (1) Take a density board with a thickness of 0.9cm, and use a punch die to punch out a sheet of the required size according to the medal specifications to obtain panel 1.

[0040] (2) Place the obtained panel 1 on a steaming rack, steam at 100°C for 3 minutes, then dry it, and stick wood grain paper 3 on one side of the panel 1.

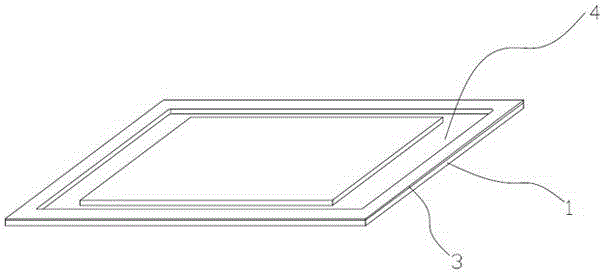

[0041] (3) Put the panel 1 pasted with the wood grain paper 3 into a hot-pressing mold, and heat press at 170°C for 2 minutes, so that the side of the panel 1 pasted with the wood grain paper 3 forms a concave-convex pattern 4 (see figure 1 ).

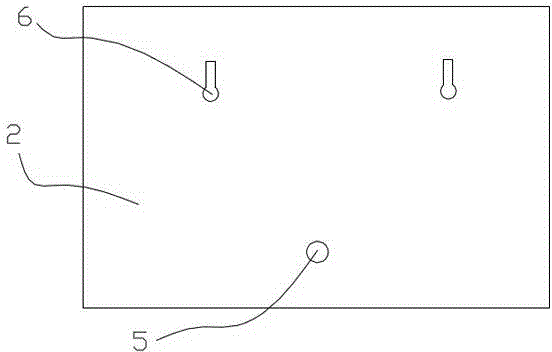

[0042] (4) Take another density board with a thickness of 0.6cm, punch out a sheet with the same shape as the panel 1, and punch out the bracket mounting hole 5 and the suspension groove 6 on the sheet to obtain the back panel 2 (see figure 2 ).

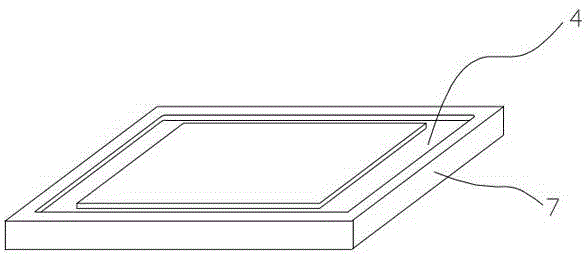

[0043] (5) Paste the wood grain paper 3 on one side of the back panel 2, so that the sides of the panel 1 and the back panel 2 pasted with the wood grain p...

Embodiment 2

[0046] (1) Take a density board with a thickness of 0.8cm, and use a punch die to punch out a sheet of the required size according to the medal specifications to obtain the panel 1.

[0047] (2) Place the obtained panel 1 on a steaming rack, steam at 110°C for 2 minutes, then dry it, and stick wood grain paper 3 on one side of the panel 1.

[0048] (3) Put the panel 1 pasted with the wood grain paper into a hot pressing mold, and heat press at 180°C for 1.5 min, so that the side of the panel 1 pasted with the wood grain paper 3 forms a concave-convex pattern 4.

[0049] (4) Take another MDF with a thickness of 0.7cm, punch out a sheet with the same shape as the panel 1, and punch out the bracket mounting holes 5 and the suspension grooves 6 on the sheet to obtain the back panel 2.

[0050] (5) Paste the wood grain paper 3 on one side of the back panel 2, so that the sides of the panel 1 and the back panel 2 pasted with the wood grain paper 3 are facing outward, and after the p...

Embodiment 3

[0053] (1) Take a density board with a thickness of 0.7cm, and use a punch die to punch out a sheet of the required size according to the medal specifications to obtain panel 1.

[0054] (2) Place the obtained panel 1 on a steaming rack, steam at 120°C for 1 min, then dry it, and stick wood grain paper 3 on one side of the panel 1 .

[0055] (3) Put the panel 1 pasted with the wood grain paper 3 into a hot-pressing mold, and heat press at 190°C for 1 min, so that the surface of the panel 1 pasted with the wood grain paper 3 forms a concave-convex pattern 4 .

[0056] (4) Take another density board with a thickness of 0.8cm, punch out a sheet with the same shape as the panel 1, and punch out bracket mounting holes 5 and hanging grooves 6 on the sheet to obtain the back panel 2.

[0057] (5) Paste the wood grain paper 3 on one side of the back panel 2, so that the sides of the panel 1 and the back panel 2 pasted with the wood grain paper 3 are facing outward, and after the panel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com